Polypropylene bag production line (15000 pcs/day)

Out of stock

All kinds of products are sold packaged today. For this reason, polypropylene bags serve as an excellent packaging product for building materials, flour products, sugar products and even poly products. Therefore, AFEX-GROUP company decided to present this profitable business to you. The most important infrastructures for production are:

242,300$

Out of stock

- Building: space for production of not less than 1300 m2;

- Power supply: 380v 50hz electric current and 500kw/h transformer;

- Technical water for cooling;

- Work force: 12 people

- The building must have a ventilation system

List of equipment in the line:

- Mixer 1m3

- Extruder line

- Thread winding equipment

- Bag weaving equipment – 6 pieces

- Bag cutting, sewing and 4-color printer equipment

- Waste bag recycling granulator

- Equipment for hydraulic pressing of finished bags

MIXER

The start of production starts with mixing the products in the Mixer. The main raw material is PP (polypropylene) with a small amount of Masterbatch and other polymers added.

| Mixer | |

| Sigimi | 100kg |

| Motor speed | 4kw |

| Rotation speed | 300 |

| Weight | 700kg |

| Voltage | 380v |

| Dimensions | 1700*1400*2900 |

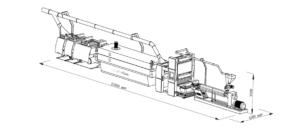

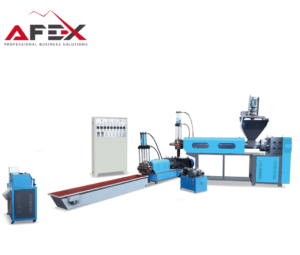

EXTRUDER LINE

It is one of the most important parts in extruder production. The production capacity of the extruder is selected depending on the number of weaving equipment you will receive. Extruder is considered part of making yarn for bag weaving from granule. Depending on the type of bag, its thickness and width can be changed.

The equipment produces tapes (threads) by heating polypropylene and high-density polyethylene. These threads then go to the winding equipment. The equipment can use 100% recycled PP(polypropylene) and PE(polyethylene), powder or granule form PP and high density PE as raw materials. Extruder screw and cylinder are made of 38CrMoA1A alloy steel. If the equipment is treated with nitrogen, its strength will increase even more. Equipment rollers are coated with hard Cr(chromium) material.

| EXTRUDER | |

| Screw dysmetry | 125 mm |

| Rotation speed | 20-80 times/min |

| Extruder power | 30kw |

| Heating power | 80kw |

| Motor power | 3-5,5kw |

| Oven heating power | 35kw |

| Tape (thread) thickness | 0,025-0,08mm |

| Sigimi | 50-100kg/h |

| Installation dimensions | 20500*2200*1450mm |

| Weight | 8000kg |

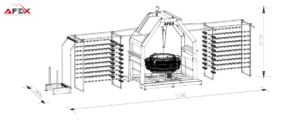

THREAD WINDING PART

In this part, the finished threads are wound on special spools. The wrapping process is controlled by a computerized system. This part is also selected depending on the number of pieces of weaving equipment.

This equipment is equipped with a 2.2/3 kw motor to increase energy efficiency using the latest technologies. The parts in the equipment are easily replaced, due to which the spare parts wear less, move more stably and roll flat.

| Wrapping equipment | |

| Number of spindle layers | 5 |

| Number of spindles | 220 |

| Ribbon spindle width | 200mm |

| Winding speed | 30-160 |

| Main engine power | 2,2kw |

| Winding motor power | 9kw |

| Installation dimensions | 6200*1620*1600mm |

| Weight | 3400kg |

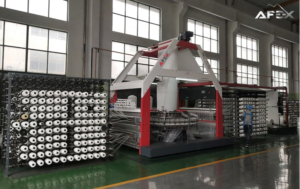

BAG WEAVING EQUIPMENT

Weaving equipment will vary depending on the diameter and density of the product you are producing. Our widely used bag weaving machines are 4G and 6G models. If you intend to produce bags intended for Big bag, i.e. 1 ton products, then 10G-12G models are suitable for you. To change the diameter of the bags, you need to add molds for a special cylinder.

If we compare with old models, this equipment has more and better facilities. For example, the principle of operation of the equipment is simple and stable, no special oil is needed, it emits less than 82 dB (decibels).

| WEAVING EQUIPMENT | |

| Rotation speed | 140-180ps/min |

| Hardware power | 4,5kw |

| Sigimi | 65-120metr/h |

| Main engine power | 2kw |

| Dimensions | 8500*2200*2650mm |

| Weight | 2000kg |

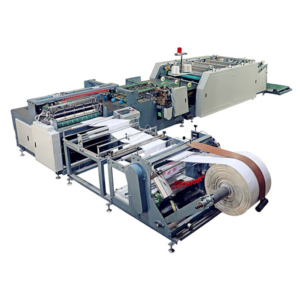

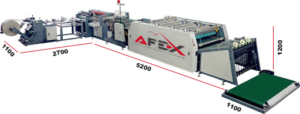

BAG CUTTING, SEWING AND 4 COLOR PRINTER EQUIPMENT

This equipment outperformed previous models and production processes, significantly speeding up the bag production rate. Cutting and lining the bags by hand is a labor-intensive and labor-intensive process. Therefore, it is advisable to entrust this part to automatic equipment.

Equipment features

1) Due to the fully automated equipment, one worker can manage all processes in the equipment.

2) The whole equipment is made of Q235 iron, so it works faster and more stable.

3) It is possible to install a hot cutter and a cold cutter in one piece of equipment. It is enough to press one button to change the cutting blades.

4) There is less damage to the environment due to the smoke absorption function.

5) Inks are automatically poured into the printer.

6) There is a two-layer drying system. This will help the bags dry faster.

| Cutting, sewing, printer equipment | |

| Speed | 40-50ps/min |

| Max cutting width | 800mm |

| Cutting accuracy | 650mm |

| Bending method | One or two floors |

| Max coloring width | 1350mm |

| Total power of motors | 6,45kw |

| Air capacity | 0,4metr k/min |

| Installation dimensions | 12*4,5*1,3m |

| Equipment weight | 9000kg |

WASTE BAGS RECYCLING GRANULATOR

Whether we like it or not, as with any business, the bag manufacturing business will sometimes produce waste bags. For this reason, it is advisable to turn some non-standard bags into pellets and use them again for yarn production and new bags.

| GRANULATOR | |

| Screw diameter | 85mm |

| Screw rotation speed | 10-110 min |

| Motor power | 22 kw |

| Production volume | 60kg/h |

| Installation dimensions | 5800*1250*1100mm |

| Weight | 2000kg |

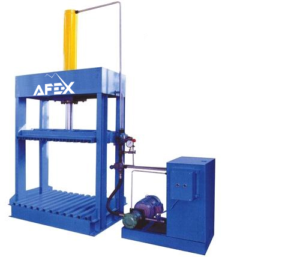

HYDRAULIC PRESSING EQUIPMENT FOR READY BAGS

Ready-made bags are pressed with a force of 60T to minimize transport costs during delivery to the customer. This packaging process is quite simple and does not require specially qualified personnel.

| PRESSING EQUIPMENT | |

| Pressure | 60 ton |

| Motor power | 7,5kw |

| Installation dimensions | 2600*930*2600mm |

| Weight | 1800 kg |

The stages of bag production consisted of these parts. If you need information on types larger or smaller than this production volume, you can contact our offices.

Based on 0 reviews

Show reviews in all languages (2)

There are no reviews yet.