PVC decorative panels production line

Out of stock

List of required equipment:

- Delivery equipment 3 pcs

- PVC mixer

- Vibrating sieve

- Portable bunker (silo) 2 pcs

- Extruder equipment

- Vacuum calibration equipment

- Equipment for straightening PVC panels and bringing them to the next stage

- Laminating and stamping equipment

- Cutting equipment

- Finished product assembly equipment

- PVC film cutting equipment

- PVC crushing crusher equipment

- Special pulverizer (mill) for PVC

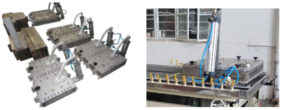

- Molds

98,700$

Out of stock

Automatic delivery equipment

Automatic delivery equipment serves to deliver raw materials and products to the equipment. This line requires 3 pieces of delivery equipment.

The first delivery equipment is loaded with raw materials and delivered to the mixer.

The raw material coming out of the mixer goes to the second delivery equipment and is delivered to the vibrating screen through it. Sifted raw materials are put into a portable hopper through the third delivery equipment. The portable hopper is rolled up to the extruder equipment, the raw material from the hopper is loaded into the fourth delivery equipment and delivered to the extruder through it.

| First delivery equipment | |

| Bunker capacity | 200 kg |

| Motor power | 2.2 sq |

| Delivery pipe diameter | 159 mm |

| Second and third delivery equipment | |

| Product transfer rate | 200 kg/h |

| Motor power | 2.2 sq |

| Delivery pipe diameter | 133mm |

PVC mixer

PVC raw materials and chemical additives were mixed using a mixer. Raw materials are put into the heating mixer at the first stage, and at the next stage, the raw materials are transferred to the cooling mixer. The finished product is delivered to the next equipment using an elevator.

The total production capacity of the mixer: 500 kg/h

The mixer consists of the following parts:

- Heat mixer

- Cooling mixer

- Automatic delivery elevator

- Electric control unit

Heat-mixing mixer

| Total size | 300 liters |

| Production capacity | 500 kg/h |

| Motor power | 55 sq |

| Heating power | I12 sq |

| Quantity of blades | 3 pcs |

| Mixing time | 8-10 minutes at a time |

Cooling mixer

| Total size | 600 liters |

| Production capacity | 500 kg/h |

| Motor power | 11 sq |

| Rotary blade speed | 60 rpm |

| Type of cooling | Water cooling |

| Cooling time | 10-12 minutes at a time |

| Weight | 4500 kg |

| Size | 4600x3000x3000 mm |

Vibrating sieve

The raw material delivered by the elevator falls into the sieve. Sieve sifts raw materials using vibration. The product coming out of the sieve goes to the elevator.

| Motor power | 3 sq |

| Sieve diameter | 2000 mm |

| Material | SS 304 |

| Production capacity | 2000 kg/h |

Portable bunker

The portable hopper has four wheels and is used for transporting raw materials and products.

| Bunker size | 1500l/h |

| Bunker wall thickness | 3mm |

| Bunker diameter | F1100 mm |

| Material | SS304 |

Extruder equipment

Raw materials passed through a mixer and a sieve are put into the hopper of the extruder using a special hopper. From the hopper, the product enters the extruder, where the raw material is squeezed through a small hole with a rotating spiral screw. As a result, the raw material is compressed and has a solid shape. The resulting pressure increases the temperature of the raw material, which helps to increase the efficiency of mixing the components. At the next stage, the resulting mass enters the plasticizing zone, where it is heated and melted. The melted mass is poured into a mold. The raw material comes out of the mold in the form of a plastic panel.

Don’t forget the molds here. Molds of different sizes are placed inside the extruders. In this case, the size of the mold is made according to the customer’s request. Dimensions of molds: 250, 300, 350, 400 mm.

Screw diameter: 55 /120 mm

The length of the auger is :1245 mm

Product width (mould) : 200-500mm

Screw rotation speed : 1-34.8 rpm

Heating power : 14 kW

Nitriding hardness : 940 HV

The depth of nitration is : 0.4-0.7 mm

Extruder hopper heater: Cast aluminum heater

Heating zones: 4

Extruder hopper cooling method : Air cooling

Vacuum calibration and cooling equipment

The function of vacuum calibration equipment is to maintain the shape of plastic pipes. The plastic panels coming out of the extruder are hot. It is very easy for them to change shape when it is hot. This equipment solves this problem by vacuuming and cooling.

The power of the vacuum pump is 4 kW

Vacuum pump pressure -0.08 Mpa

Vacuum parts 20 pcs

Cooling parts (using water) 20 pcs

The length of the vacuum cooling table is 1500 mm

The capacity of drying PVC panels is 1.5 kW

Equipment for straightening PVC panels and bringing them to the next stage

This equipment is used for straightening plastic panels. The panels pass between two belts and are pressed and transferred to the next stage.

The maximum pulling force is 15000 N

The speed of pulling is 0.5-5 m/min

The power is 1.5 kW

The material of the traction block is Rubber

Laminating and stamping equipment

The finished panels from the laminating and stamping equipment are passed through special rollers, in this process a PVC film with a special image and pattern is glued and not stamped for a strong adhesion.

The maximum panel width is 400 mm

The maximum panel thickness is 2-80 mm

The total power is 1.7 kW

Conveyor speed is 5-30 m/min

The size of the equipment is 2200×900 mm

Cutting equipment

Our equipment cuts plastic panels according to the length required by the customer. A distinctive feature of the equipment is that it does not emit any dust or debris when cutting a plastic panel. When plastic panels are cut on conventional equipment, scraps of those panels are formed and as a result the quality of the product is damaged. This equipment does not produce any extra parts or dust.

The maximum cutting size is 400 mm

Blade material High-quality steel

Blade diameter is 90 mm

The required air pressure is 0.3 Mpa

Control style PLC control panel

Finished product assembly equipment

The PVC panels coming out of the cutting equipment go to the collecting equipment. This equipment is 4 meters long, and the collecting part is made of stainless metal.

The length is 4 meters

The material of the panel assembly part is SS304

PVC film cutting equipment

The function of this equipment is to cut PVC films from large rolls into small PVC panels.

The maximum winding diameter is 400 mm

The maximum speed is 200 m/min

The maximum cutting speed is 50-180 m/min

Cutting width 50-500 mm

The diameter of the winding shaft is 76 mm

Voltage 380V 50 HZ

The power is 4 kW

The weight of the equipment is 2000 kg

The size of the equipment is 2800x1500x1600 mm

PVC crushing crusher equipment

Product reception area is 505*320mm

The diameter of the rotating blades is 400 mm

For PVC panel width <500 mm

The number of rotating blades is 5 pieces

The rotation speed is 500r/minute

The number of fixed blades is 2 pieces

Blade material SKD-11

The size of the output product is 10 mm

Capacity 250-350kg/hour

The power of the main engine is 15 kW

The power of the air blower is 4 kW

The volume of the silo is 0.5m3

Special pulverizer (mill) for PVC

PVC pulverizing equipment, that is, it can also be called a mill by another name. It is used for grinding plastic and other products of solid and granule type. Raw materials are delivered to the grinding part through the vibrating delivery part. A high-speed mill grinds the product, and the product from it is directed to the next stage through a special suction unit. When the products are added in the required dose, they are crushed in a mill and brought to the form of a uniform powder. Larger pieces that did not pass through the sieve are thrown back into the mill, and the process is repeated again. This equipment is mainly used for crushing LDPE, LLDPE, RPVC, HDPE, UPVC, PC and other plastic brands. Almost all plastic extrusion lines use this equipment service.

Made in China

Voltage 380v 50hz

Motor capacity is 37 kw/h

Grinding mill external diametric 500mm

The number of internal blades is 12 pieces

The number of moving blades is 24 pieces

Control panel Push-button control panel

Suction fan motor 3kw

The volume of the hot mixer is 300L

Mixer rotation speed 475-950 r/min

Product release method is 0.75 kw ventilation method

Sieve size 30-80 (selectable)

Production capacity is 180-280 kg/hour

The size is 2500*2100*3800 mm

It weighs 2100 kg

Molds

Video from the production process

There are no reviews yet.