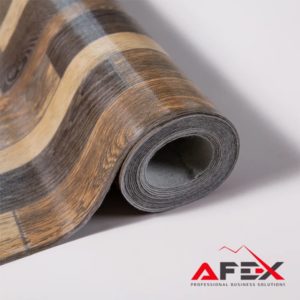

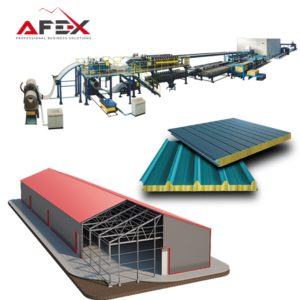

linoleum production line

Out of stock

The demand for construction materials in our country is increasing more and more. Because of this, we can show the increasingly developing housing construction sector in our country. The construction of new houses and buildings increased the sales of such materials. Linoleum is one of the most widely used materials in housing.

AFEX-GROUP company will continue to offer the next profitable equipment to entrepreneurs of our country. With the help of this production line, it is possible to produce high-quality and thick linoleum with various designs

365,000$

Out of stock

General information

Production volume: 600-800 kg/hour

Product size: width – 980 mm (changes according to the customer’s request), thickness 2-8 mm

Voltage: 380V 50Hz

Total capacity: 200 kw/h

Necessary raw materials: PVC powder, non-woven fabric, composite films

Required area size: 150-200 square meters

Number of workers: 7-8

Equipment list

- Twin screw extruders

- Hydraulic sieve

- Molds (2 sets)

- Three-roller forming equipment

- Composite laminate heating equipment

- Laminating part

- Equipment for wrapping non-woven fabric

- Temperature control equipment

- Roller cooling equipment

- Cooling section (with cutting section)

- Leveling equipment

- Transverse cutting equipment

- Electronic control panel

80/156 pair of extruders

The most basic equipment of the production line is, of course, extruders. In this extruder, quality metals 38CrMoAIA and 20CrMoTi are used, and spare parts are made in Japan and China. Due to the presence of a total of 5 heating zones in the equipment, raw materials are melted in good condition and quality products are produced.

Nitriding thickness: 0.5-0.7 mm

Main motor: AC motor (Brazil)

Engine power: 55 kW

Motor speed: 0-1500 r/min

Screw speed: 0-50 r/min

Motor type: 3-phase asynchronous motor

Hydraulic sieve

The main function of this equipment in the line is to clean the excess parts and waste found in the product. This, in turn, helps to increase the quality of the product.

Form F150: hydraulic, two-station

Heating zones: 3

Heating capacity: 12 kW

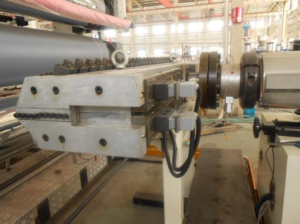

Molds

Number of molds: 2 (1 for upper layer, 1 for lower layer)

Material: steel

Heating zones: 7

Mold width 1200 mm

Product width: 980 mm

Product thickness: 2-8 mm

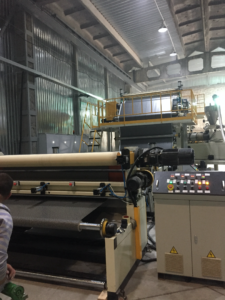

Three-roller forming equipment

Roller diameter: 400mm

Roller width: 1400 mm

Chrome thickness: 0.08 mm

Motor power: 2.5 kW

Control panel: Sweden ABB electronic panel

Composite laminate heating equipment

Heating rollers: 3, F200 x 1400

Motor power: 0.75 kW

Control panel: Sweden ABB electronic panel

Laminating equipment

Heating rollers: 3, F200 x 1400

Motor power: 0.75 kW

Control panel: Sweden ABB electronic panel

Non-woven fabric wrapping equipment

Roll width: 1200 mm

It is easy to remove the rollers

Material: Aluminum

4-station temperature control equipment

Cooling method: oil

Average temperature: 160C

Heating power: 4×12 kw

Three sets are used for three-roll forming equipment, and one set is used for preheating the rolls, when there is excess pressure, when the temperature is high, when there is a shortage of oil, and other alarm functions.

Roller cooling equipment

Roller diameter: 3×400 mm, 1400 mm

Motor power: 1.5 kW

Cooling method: internal water cooling

Control panel: Sweden ABB electronic panel

Cutting equipment

Length: 6m

Roller: Aluminum

Knives: 2 sets

There is a feature of collecting the cut parts

Straightening-transmitting equipment

Size: F250x1400 mm

Roller material: nitrile rubber

Motor power: 2.5 kW

Control panel: Sweden ABB electronic panel

Control: pneumatic

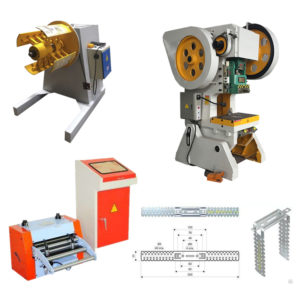

Transverse cutting equipment

Pulling roller: F 180 x 1400 mm

Blade: Triangular

Control panel: Sweden ABB electronic panel

Screen: PLC screen

Electronic control panel

Operating system: Siemens TP1200

PLC screen: Siemens

Anti-low voltage section: Schneider

Video footage of the process

There are no reviews yet.