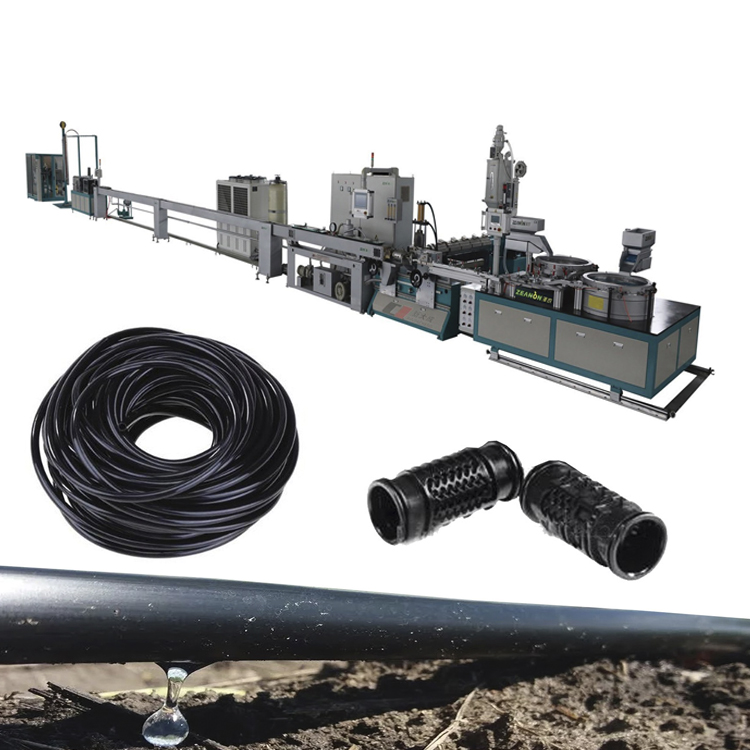

Production line of drip irrigation hoses

Out of stock

As a result of consistent reforms being carried out in our country, special attention is paid to each field. For example, we can cite education, medicine, food and other fields. One of such fields is definitely agriculture.

Our line, which we want to present to you in this post, is becoming more and more relevant in the field of agriculture. Because more attention is being paid to agriculture in order to meet the growing demand of the population for food. There is no doubt that the most important thing in agriculture is the supply of water to crops. Saving water is also important here. That is why farmers are switching to drip irrigation. We hope that you will be able to make a sufficient contribution to the development of the agricultural sector through our production line.

68,900$

Out of stock

General information

- Hose diameter: 12mm-20mm

- Hose thickness: 0.6mm-1.0mm

- Hole spacing: 200mm-1500mm

- Production speed: 40-45m/minute

- Punching speed: 300 per minute

- Hose reel length: 500m-1000m

- Working power: 65KW

- Maximum extruder capacity: 120kg

- Electronic control system: PLC

- Weight of the whole line: 6000 kg

- Line dimensions: 25m*3.5m*2.4m (length*width*height)

- Required area: 90 square meters

- Number of workers: 2

- Raw materials: PE and colors

Equipment list

Main

- Equipment and conveyor for correcting the hole part

- Extruders and molds

- Vacuum equipment

- Water cooling unit

- Hole forming equipment

- Supplier equipment

- Two-round wrapping equipment

Optional

- Hydraulic filter equipmen

- Color line extruder

- Laser printer

- Camera control system

- Chiller

- Mixer

- Air compressor

So, we got acquainted in detail with the list of all the necessary information and equipment. Now, we can consider the production process step by step.

At the first stage, we use the sealing device for the holes

In the photo above, you can see that the green belt conveyor is dropping the pre-prepared parts into the pot. These parts were adjusted to reach the next equipment inside the boiler. In short, these hole pieces are covered over the tubes that take shape inside the extruder.

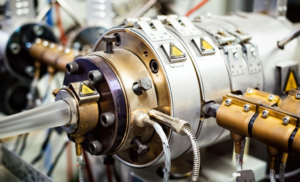

In the second step, the extruder shapes the hoses

The most basic equipment of this production line is, of course, the extruder and molds. First of all, the equipment melts the raw materials. Then, with the help of molds, it produces hoses of the required thickness and diameter (technical parameters can be adjusted using the LCD screen).

As mentioned earlier, we need to melt the raw materials. For this we need the above equipment. The equipment melts the raw material and the melted raw material goes from the bottom to the next equipment.

Our melted raw materials are formed in the required dimensions in this mold. A hole stopper is also installed inside the equipment. The hoses taken out of the mold are immediately cooled with water.

In the third stage, our formed hoses go to the vacuum equipment

Briefly, the main purpose of using vacuum equipment is to ensure that the diameter of the hoses that come out of the mold does not change. Because after the extruder and the mold, the hoses are in a boiling state and their shape can change. That’s why we use vacuum equipment.

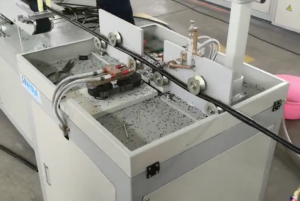

In the fourth step, we cool the hoses with water

In the fourth step, we cool the hoses again with water. The sole purpose of this is to improve the quality of our hoses by hardening them.

In the fifth stage, a hole is left in the hoses

The turn came to the most basic feature of the hose. A feature that differs from other hoses is the presence of holes. For this we need a device that makes holes on both sides.

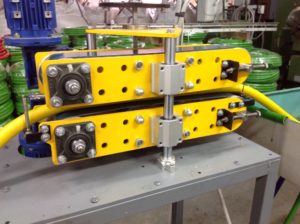

In the sixth stage, the product is transferred to the supplier’s equipment

At this stage, our finished hose should be delivered to the wrapping equipment. That is why we need the above equipment. He straightens and delivers the hose.

At the seventh stage, we wrap the hoses

We use two circular winding machines to wrap hoses. And with that, all processes have come to an end. Our drip irrigation hoses are ready for sale.

Below we have decided to provide you with optional equipment. You can produce the required product without this equipment. You can improve the quality and appearance of your products through these devices. Let’s get to know one by one.

Hydraulic filter equipment

The function of the equipment is as follows: sometimes recycled raw materials can be used. This is where the equipment freezes. Cleanses old raw materials. If new materials are always used, this equipment will not be needed.

Color plotting equipment

The device has the ability to draw 1, 2 or 4 colored lines.

Laser printer

The equipment can write any letters and words on the hoses

Camera control system

The function of the equipment is to notify when an error occurs. This is redundant

prevents the production of unusable hoses.

Chiller

The equipment is needed to change the water temperature. Because it’s normal

water temperature is sufficient to produce hoses of the required quality

may not be. The equipment is especially needed in summer.

Mixer

It is necessary to mix raw materials and colors.

Air compressor

The equipment helps to increase the quality and volume of production. The equipment is of good quality

high pressure air is also needed for its operation. This is the purpose of the equipment

consists of

Video footage of the line operation

This is the end of the information we want to present to you. now,

we can get acquainted with the prices of the equipment.

| Prices (Main) | |

| Drilling equipment and conveyor | $ 68900 |

| Extruders and molds | |

| Vacuum equipment | |

| Water cooling unit | |

| Hole forming equipment | |

| Equipment supplier | |

| Double-circuit equipment |

| Prices (Optional) | |

| Hydraulic filter equipment | $ 4950 |

| Color line extruder | $ 3750 |

| Laser printer | $ 4300 |

| Camera control system | $ 9750 |

| Chiller | $5400 |

| Mixer | $ 2250 |

| Air compressor | $ 5700 |

| TOTAL | $ 36100 |

There are no reviews yet.