Construction equipment

Whipped polyethylene tubes production line for insulation

Availability:

Out of stock

Polyethylene pipes whipped for insulation are an excellent insulation tool for heating systems, hot and cold water supply and sewage systems.

Pipe wall thickness: 15 mm. Inner diameter: from 6 mm to 86 mm. The Material is moisture-resistant, retains its physical and chemical properties, does not mold, does not rot, is oil and gasoline-resistant, flexible and lightweight, easy to install and glue.

49,000$

Out of stock

Features of insulation pipes:

- Reliably protects against condensation and heat loss.

- Environmentally friendly, safe to use, does not require the use of personal protective equipment.

- Materials do not burn

- Swallows noise.

- Resistant to moisture.

- Significantly reduces heat losses, which ultimately saves money.

- Operating temperature range: -40 to +90 ° C.

- The service life is 50 years.

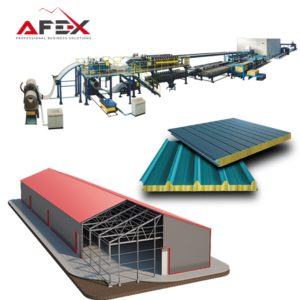

Overview of the line

Equipment and devices within the line

Automatic raw material delivery equipment

| Delivery speed | 200 kg / h |

| Motor power | 0.75 kw |

| Delivery height | Up to 3 meters |

Automatic raw material (powder-shaped) conveying equipment

| Delivery speed | 0.5-2 kg / h |

| Motor power | 0.75 kw |

Extruder equipment

| Motor (explosion proof | Motor, Brand: Siemens |

| Motor power | 22 kW |

| Reducotor | Polished metal |

| Schesterna material | high quality steel |

| Surface hardness | 54-62 HRC |

| Accuracy | Class 6 |

| Vint | |

| Screw diameter | Daschatlari75mm |

| Screw material | Given nitrogen ishkov. Surface hardness above 38CRMNALA HV900 |

| Heating and cooling | |

| Heating zones | Zone 8 |

| Heating circle material for plasticizing part | stainless steel |

| Circle material for the cooling part | explosion-proof cast aluminum |

| Cooling method | With water |

Bhutan delivery system

| Pump type | High pressure |

| Type of foam-forming equipment | Diluted butane dosing pump |

| Transfer rate | 16L / hour |

| Output pressure | 10-30 Mpa |

| Motor (explosion proof | 2.2 kw |

Anti-compression system (GMs pump)

| Pump type | Superior |

| Single cylinder anti-compression gear type | Dispensed glycerin monostearate dosing pump |

| Transfer rate | 3.6 L/H |

| Dosage container size | 10L |

| Output pressure | 10-30 Mpa |

| Engine power | 0.75 kW |

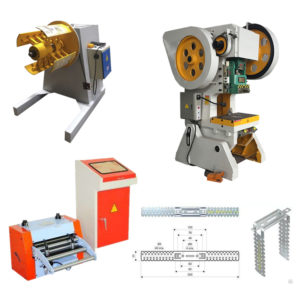

Automatic high speed hydraulic setka change system

| Hydraulics station | 1 vol. |

| Electrical appliances and pipes | 1 set per engine |

| Motor power | 3 kw |

Extruder head (golovka) and mold

| Structure | Round extruder has adjustable and pressure measuring device output head |

| Materials | Thermally machined high quality steel |

| Temperature control zone | Zone 3 |

| Temperature control accuracy | ±1° C |

| Heating power | 3 kw |

| Water cooling system in the head part | Available |

Air cooling ring

| Cooling type | Using an air loop |

| Fans | 3pcs x 0.33 kw |

| Cooling ring diameter | Depending on the diameter of the product |

Pipe pulling and cutting equipment

| Capacity | 2.2 kw |

| Cooling type | Air ring |

| Speed control system | Available |

| Length measurement system | Available |

| Management system | Available |

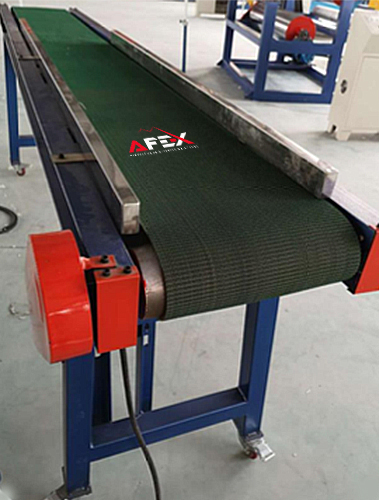

Conveyor

| Length | 3 m |

| Kuvai | 1,5 kVt |

Management system

- The control system is equipped with an air cooling fan to ensure that all electrical components work in good condition.

- To ensure that the equipment always works in the best condition, all parts in the electric control Cabinet have been used from internationally famous brands.

Tower for cooling with water

| Watercourse | 50m3 / so |

| Size | 2215x2215x2830 mm |

| Fan diameter | 1400 mm |

| Motor power | 1.5 kw |

Air compressor

| Motor power | 7,5 kVt |

| Size | 180 L |

There are no reviews yet.