Mix production equipment AF-L011

Out of stock

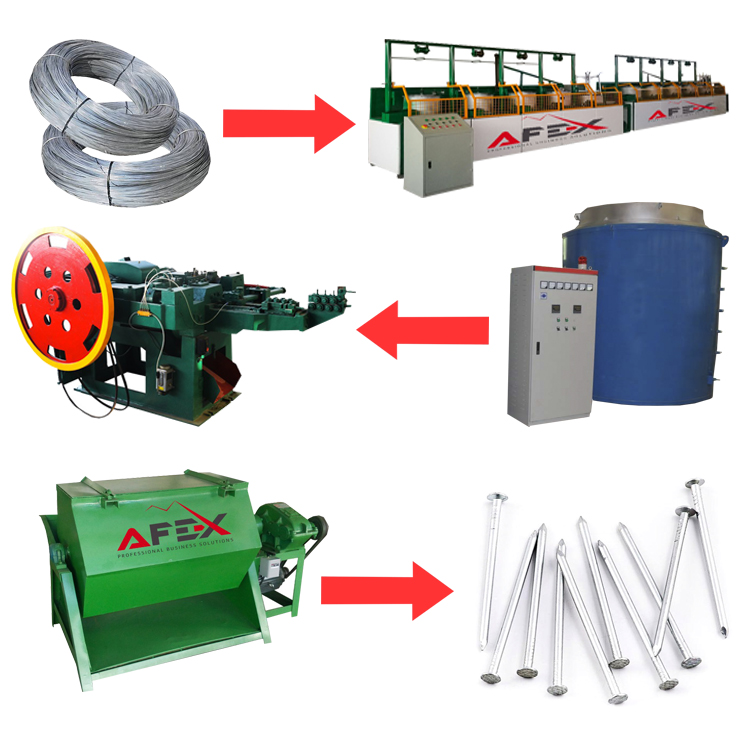

We have decided to provide you with a nail production line based on the demands of many of our customers. Mix is currently considered one of the most popular building materials in construction works in our country. Mix production business is considered more effective than other businesses as it allows you to get quick income and easy to find buyers for your products. You can get to know the production process closely through our recommended line below.

128,000$

Out of stock

WIRE STRETCHING EQUIPMENT

Entrepreneurs who want to make more money from the business of mixing, buy a wire with a diameter of 5.5 mm and stretch it to the diameter they need. In this process, the mass of the wire does not increase or decrease. In this line, you can also make a profit by selling different diameter wires, there is a difference between the prices of thick diameter wire and non-thick diameter wire. The wire stretching line we recommend can stretch from 5.5mm to 1.2mm. Wire stretching is carried out in two stages, and in the first stage it is stretched up to 2 mm.

| Wire stretching equipment | |

| Produced | China |

| Model | APL560/APL480 |

| Incoming wire diametric(MAX) | 6.5 mm |

| Outgoing wire diametric(MIN) | 1.2mm |

| Power consumption | 88kw/h |

| Speed of operation | 50-60m/min |

| Motor type | Inverter |

| Control Panel | PLC+buttom |

WIRE HEATING FURNACE

Wires stretched up to 2 mm are inserted into a heating furnace and kept at a temperature of 850 C for 2-3 hours. This process serves to increase the elasticity of the wire. At the end of this process, you can again stretch the wire to a diameter of 1.2 mm.

| Wire heating furnace | |

| Produced | China |

| Model | HF2000 |

| Internal temperature | 950C |

| Working temperature | 850C |

| Power consumption | 120kw/h |

| For heat storage part | 35kw/h |

| Heat up time | 2-3 hours |

| Control panel | PLC+buttom |

| Production volume | 2 tons/at one time |

TIP ROLLER

The tip roller equipment prepares the end of the wire for the stretching equipment, that is, by making the three parts into a flat shape, it brings it into a state where it rolls well on the drum.

| Type roller | |

| Produced | China |

| Model | TR6 |

| Internal temperature | 950C |

| Voltage | 380v50hz |

| Power consumption | 3kw/h |

| Wire diameter | 6.5-2mm |

WIRE WELDING EQUIPMENT

Wire welding equipment is also involved in the wire stretching process. This equipment connects the end of the wire in the new wire wrap by welding when the wire in the wire wrap is depleted. After that, the wire will not be disconnected.

| Wire welding equipment | |

| Produced | China |

| Model | DH 6.5 |

| Weight | 150 kg |

| Voltage | 380v50hz |

| Power consumption | 10kw/h |

| Wire diameter | 6.5-2mm |

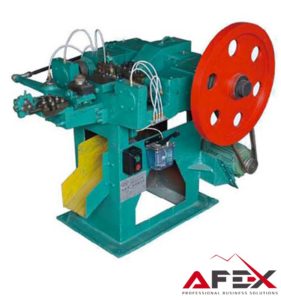

MIX PRODUCTION EQUIPMENT

The finished coils of wire are placed in the nailing equipment. Depending on what size nail you need, you can choose a nailer. If you want to produce all kinds of nails, then it is advisable to buy the equipment recommended below.

| Mix release equipment AF-1C(9-25mm) | |

| Produced | China |

| Model | AF-1C |

| Weight | 560 kg |

| Voltage | 380v50hz |

| Power consumption | 1.5kw/h |

| Wire diameter(MIN) | 0.9mm |

| Wire diameter(MAX) | 1.6 mm |

| Size | 1440*1040*1270mm |

| Speed of operation | 450 pieces/min |

| Mixing equipment AF-2C(20-60mm) | |

| Produced | China |

| Model | AF-2C |

| Weight | 1200 kg |

| Voltage | 380v50hz |

| Power consumption | 2,2kw/h |

| Wire diameter(MIN) | 1,2mm |

| Wire diameter(MAX) | 2,8 mm |

| Size | 1640*1215*1370mm |

| Speed of operation | 350 pieces/min |

| The length of the mix | 20-60 mm |

| Mixing equipment AF-3C(25-85mm) | |

| Produced | China |

| Model | AF-3C |

| Weight | 1400 kg |

| Voltage | 380v50hz |

| Power consumption | 3 kw/h |

| Wire diameter(MIN) | 1,8mm |

| Wire diameter(MAX) | 3,8 mm |

| Size | 1990*1200*1250mm |

| Speed of operation | 300 pieces/min |

| The length of the mix | 25-85 mm |

| Mixing equipment AF-4C(25-85mm) | |

| Produced | China |

| Model | AF-4C |

| Weight | 1700 kg |

| Voltage | 380v50hz |

| Power consumption | 4 kw/h |

| Wire diameter(MIN) | 1,8mm |

| Wire diameter(MAX) | 3,8 mm |

| Size | 2200*1400*1350 mm |

| Speed of operation | 190 pieces/min |

| The length of the mix | 30-110 mm |

| Mixing equipment AF-5C(70-170mm) | |

| Produced | China |

| Model | AF-5C |

| Weight | 1900 kg |

| Voltage | 380v50hz |

| Power consumption | 5,5 kw/h |

| Wire diameter(MIN) | 3mm |

| Wire diameter(MAX) | 6 mm |

| Size | 2800*1500*1550mm |

| Speed of operation | 170 pieces/min |

| The length of the mix | 70-170 mm |

POLISHING EQUIPMENT

After the nail comes out of the nailing equipment, it is thoroughly polished. During the polishing process, your nails will become brighter and avoid unnecessary questions for customers. In the process of polishing, as well as in the process of nail production, problems such as the error caused by the speed of the knife, i.e. the three parts not opening well, are eliminated.

| Mix polishing equipment PM-600 | |

| Produced | China |

| Model | PM-600 |

| Weight | 11100 kg |

| Voltage | 380v50hz |

| Power consumption | 2.2kw/h |

| Size | 1640*900*1000mm |

| Speed of operation | 600 kg at once |

| Duty cycle | 1-3 hours |

GRINDING EQUIPMENT

As a result of regular work with mixing equipment with metal, it is necessary to sharpen the blades installed on it frequently. Since the knives have a specific type, it is recommended to sharpen them using a special wheel.

| Sharpening equipment NG-300 | |

| Produced | China |

| Model | NG-300 |

| Weight | 200 kg |

| Voltage | 380v50hz |

| Power consumption | 0.75kw/h |

| Size | 1110*690*1200mm |

| Sharpening length | 300mm |

| Area of use | For cutting knives |

With the line recommended above, you will be able to produce nails and wires of any size. Realizing that mixing production is a profitable industry, we will help you find a qualified technologist and the necessary raw materials for production. Of course, some of our entrepreneurs may not have enough initial funds to purchase the above line, in such cases, we advise you to purchase nail-making equipment, polishing equipment, and wheels. And we undertake to conclude contracts for the wires of the diameter you need at low prices from the places where we sold the entire line.

For the above line, the buyer must fulfill the following requirements:

Indoor space of not less than 150 m2

2 workers

380 v 50 hz power supply for indoor installation

Other minor requirements as required by the engineer technologist

Video about the small line

Based on 0 reviews

Be the first to review “Mix production equipment AF-L011” Cancel reply

Related products

-

Metalworking equipment

Metal sheet CNC cutting (guillotine) equipment (6*3200)

0 out of 5(0)Key Features: Fully European design, streamlined appearance, monoblock, welded steel frame, ST44 A1 material, high tension equipment. Since the cutting beam is designed in an internal inclined structure, the slabs fall very easily and the accuracy of the products is also guaranteed.

SKU: n/a15,200$ -

Metalworking equipment

AF-K7 Pipe flattening equipment

0 out of 5(0)Conical pipe flattening equipment is the equipment used to process any metal pipes into a cone and reduce the diameter of the pipe.

Pipe materials are stainless steel, copper, carbon steel, iron, galvanized, aluminum and other metals.

The products are widely used in tables and chairs, doors and windows, railings and handles, and other fields.

SKU: n/a10,700$

There are no reviews yet.