Toilet paper production line (Fully automatic)

Out of stock

Every new entrepreneur, when starting his business, definitely aims to see a big profit. Making a big profit from business, in turn, depends on several factors. These are: the availability of raw materials, the price of the product, the seasonality of the product, the technology used and the income of the population. If all of these listed factors are found in the product produced by the entrepreneur, the sale of the product will certainly develop.

51,300$

Out of stock

The toilet paper production line also meets all the requirements mentioned above. For this reason, it is among the projects with business prospects. The production line that we offer you increases the production volume and the equipment works in fully automatic mode. Now let’s have detailed information about the production line.

General information

Production capacity: 2-3 tons/8 hours

Number of floors: 3

Number of workers: 1

Required area size: 70-80m2

Power: 25 kW

Necessary raw materials: a roll of cellulose, a package

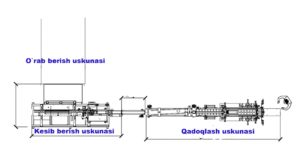

A set of equipment

- Equipment for cutting from a large package to a small package

- Automatic cutting equipment

- Automatic packaging equipment

- Compressor

Now let’s take a closer look at each of the production steps and equipment.

Production process

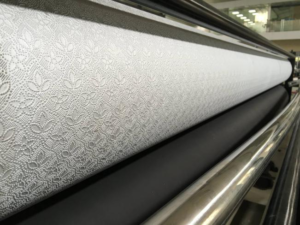

The equipment for wrapping from a large package to a small package

Before starting work, we should pay attention to 2 factors. The first is the number of layers of toilet paper. Currently, we see that manufacturers in our country are making 1, 2, and in some cases 3-story. The most common is certainly 2-story. You can produce 1, 2, 3 layers in our equipment. The second is the raw material size. The equipment can use a roll of cellulose up to 2200 mm wide. Rolls with a width of 1800 mm are mainly used in our country. The width of the raw material roll affects the production volume.

Features:

- Embossing

- Automatic wrapping, punching and cutting

- Automatic glue spraying

- Automatic pneumatic paper loading

- Automatic bushing delivery system

- Delivery equipment to automatic cutting equipment

Features:

- PLC control system is used in this model, production process is fully automated, production speed is high.

- The equipment can automatically change the bushing, as well as automatically increase and decrease the speed when changing the bushing.

- The device also has an automatic alarm feature. This feature alerts the operator when the cartridge or paper is out.

- The roll holds the cellulose using pneumatic pressure.

- The equipment can produce toilet paper both with and without a sleeve.

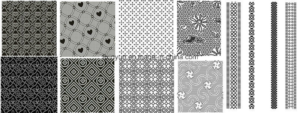

Patterned shafts are installed in the equipment. You can see our ready-made patterns in the pictures below. According to the customer’s request, special mold shafts can be made.

| Small wrapping equipment | |

| Equipment model | AFX-2200T |

| Paper width | <2200mm |

| Production capacity | 2-3 tons/8 hours |

| Winding speed | Max 280m/min |

| Control Panel | PLC screen |

| Number of floors | 3 |

| Power consumption | 6 sq |

| Equipment dimensions | 6200*3200*1900mm |

| Equipment weight | 2.5 tons |

Automatic cutting equipment

Papers coming out of the wrapping equipment are automatically sent to the cutting equipment. It does not require any labor force. With the help of the equipment, it is possible to cut in different sizes. If you want to make toilet paper, you need to cut it 10-12 cm long, if you want to make paper towels, you need to cut it longer (15-20 cm).

- LCD touch screen settings are easy to control.

- No workers are needed during the cutting process, very safe.

- It is easy to set the number of cuts and the length of cuts and can be connected with the automatic packaging machine.

- Machine settings are advanced and stable. Control parts are mainly used of quality imported parts.

-

Cutting equipment Cutting speed 80-100 times/minute Cutting length 100-200mm Cutting height 50-150mm Cutting width 70-120mm Air pressure 0.6Mpa Power 7.5kw Weight 1 ton

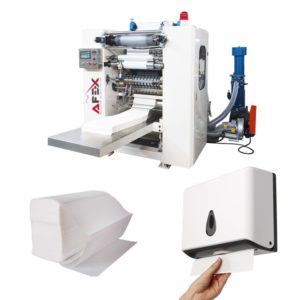

Packaging equipment

And the last stage, as always, is the block packaging equipment for convenient delivery of the product to the customer. It is possible to pack up to 2, 4, 6, 8, 10, 12 boxes depending on the requirements of the buyer in the area where you live and plan to sell your product. When you order a packing bag, don’t forget to leave holes in it that are easy to grab by hand. This will provide additional convenience for the buyer who receives your product.

- PLC control system. Machine settings can be preset.

- Only one worker is needed to operate the machine.

- With a sensor that guarantees safety.

- One machine can be used to pack products of all sizes.

| Packaging equipment | |

| Type | 2 lines |

| Packing speed | 8-15 per minute |

| Total power | 3.5kw |

| General dimensions | 6200*2900*1400 mm |

| Packaging dimensions | Length 400-600mm. Width 160-240mm. Height 160-240mm |

| Weight | 700 kg |

Compressor

Compressor

Air pressure is 0.6m3

Voltage 380V50Hz

The power is 4kw

The speed is 2890r/min

Video footage of the process

With this, our production process has come to an end. You can watch the following video to get an impression of the general process.

There are no reviews yet.