Iron fences (sets) production line

Out of stock

Hello, dear followers and customers of AFEX-GROUP. As we all know, the production sector in our country is developing more and more, and the production mechanisms are also improving. This post is about a set of equipment for the production line of iron fences (sets), which are widely used in agriculture and household, as well as in the construction industry.

39,700$

Out of stock

General information

- Wire thickness: 3mm-6mm

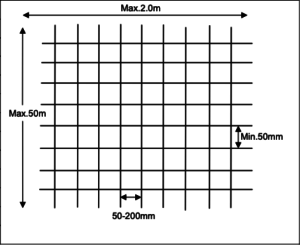

- Distance between wires: 50-200mm

- Performance: 30-40m/min

- The maximum length of the fence: 30m

- Maximum width of the grid: 2m

- Number of electrodes: 41

- Welding speed: 0-80pcs/min

- Voltage: 380V 50Hz

- Power: 125KVA

- Welding time: 10ms-1ooms

- Control panel: PLC touch screen

- General dimensions of the line: 5100*2800*1700mm

- Cooling method: by water (5.12m3/hour, at 25-30C temperature)

We found out what kind of wire mesh we can produce with our production line. Now let’s get acquainted with what equipment is included in our production line.

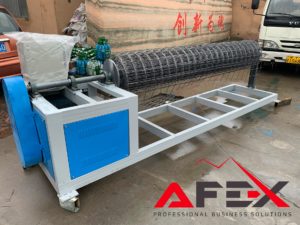

A set of equipment

- Automatic welding equipment

- Wire delivery equipment

- Wire cutting equipment

- Wire straightening equipment

- Wrapping equipment

- Finished product cutting equipment

- Water cooling system

This includes all the necessary equipment. Now we can move on to production processes.

The first stage – we will prepare the wires

Before starting the production, first of all, we need to bring the raw materials to the condition we need. Wires are in coils. For production, you need the right wire. For this, we need 4 different types of equipment: 2 different types of equipment for straightening horizontal wires, and 2 different types of equipment for straightening vertical wires.

Cutting equipment for horizontal wires

Wires are initially in coils. The function of these two devices is to straighten and cut the wires in the coil state to the required length. Please note: The maximum width of our iron fences is 2m. Our first equipment cuts the coiled wires to the required length. The second equipment consists of the delivery of coiled wires to the equipment.

| Cutting equipment | |

| Wire diameter | 3mm-6mm |

| Maximum cutting length | 3m |

| Main motor | 2,2KW |

| Additional motor | 0l,75KW |

| Production volume | 30-40m/min |

Corrective equipment for vertical wires

It’s time for the next equipment. At this stage, the wires are not cut. The wires are separated from the finished roll and straightened before the welding equipment. 2 types of equipment are also involved in this process: wire supplying equipment and correcting equipment. The equipment consists of a total of 41 electrodes.

The second stage – Wires are welded

We have reached the most important stage of our production process. At this stage, we will connect and weld the wires we have prepared vertically and horizontally. Our equipment has a welding capacity of 80 times per minute and consists of 41 electrodes. The principle of operation of the equipment is as follows:

We place the wires we cut in the first step on the upper part of the equipment. And to the second part, we connect permanent wires with equipment. Welding equipment welds these wires horizontally and vertically. You can see the progress of the work through the video below.

The third stage – Wires are coiled

After the welding stage is completed, the steel bars are cut to the specified length using special cutting equipment. The length of the iron fence can be maximum 30 meters. The welds coming out of the welding equipment are automatically sent to the wrapping equipment. After our iron fences are wrapped, they are ready for sale!!!

Based on 0 reviews

Be the first to review “Iron fences (sets) production line” Cancel reply

Related products

-

Metalworking equipment, Other equipment

Leather belt production line

0 out of 5(0)Most of the leather belts are imported products. That is why we believe that the production of this product in the territory of our country will give you good results. We first need raw leather or a leather substitute to make the product. 10 types of equipment are involved in the production process, and our company recommends these equipments to you at the most reasonable prices.

SKU: n/a25,700$ -

Metalworking equipment

AF-N7 Metal pipe winding tracer

0 out of 5(0)The advantages of the metal pipe wrapping machine are: simple operation, high production efficiency, stable forming effect, high speed and other features.

Pipe materials: stainless steel/copper/carbon steel/iron/galvanized/aluminum etc.

Application: Pipes designed for furniture, construction and other industries.

SKU: n/a11,900$ -

Metalworking equipment

Metal door production line

0 out of 5(0)Doors, including steel doors and gates, are always in demand. Modern polished steel doors and gates represent an ever-necessary home component. Therefore, the production of steel doors in the world market, this type of activity is a promising business idea, although the competition in this field is relatively high. Almost everyone can organize this activity, because the production of doors is not a technologically difficult activity.

SKU: n/a323,500$

There are no reviews yet.