Hydraulic CNC metal sheet bending (listogib) equipment (80T/2500)

Available on backorder

This equipment is used for bending steel sheets or stainless metals. Mainly used in steel metal processing industry.

13,900$

Available on backorder

| (AF-67Y-80T/2500) Detailed technical details | |

| Part names | Parameters |

| Nominal pressure | 800 KN |

| Table length | 2500 mm |

| The distance between the hulls | 2095 mm |

| Main part height | 370 mm |

| Speed of operation | 60/8/66 mm/s depending on the size of the load |

| Base engine model | Y132M-6 |

| Main motor power | 5.5 KW |

| Main motor speed | 960 r/min |

| Linear piston fault model | 10MCY14-1B |

| Linear piston failure pressure | 32 Mpa |

| Linear piston failure flow volume | 20 ml/r |

| Rear Electric Motor Counter Adjuster Part Model | 10MCY14-1B |

| Rear electric motor counter power | 0.55 KW |

| Rear electric motor speed counter | 900 r/min |

| Equipment dimensions | 2500*1500*2200mm |

1. Use of equipment:

This equipment is a metal bending (listogib) equipment. metal sheets are used to make various products. The equipment consists of part frame, working table and pressing cylinders. The main bending dies are used for a long time, do not change shape, and maintain high bending accuracy. The folding mold is processed by a special method, it can serve for a long time. The press brake also has CNC press brake, CNC steel plate bending equipment, electric-hydraulic synchronized CNC press brake. It is mainly used for bending steel sheets or stainless metals. Mainly used in steel metal processing industry. Our equipment is equipped with a high-precision PLC control panel. In it, the pressure ton can be adjusted depending on the thickness of the metal.

Hardware parts:

|

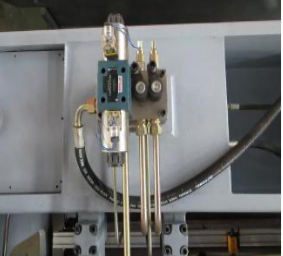

Brief description: Hardware control panel (you can ensure security through the fingerprint scanner) Hydraulic Sistema brand; BOSCH/REXROTH Hydraulic cylinder brand: BOSCH/REXROTH Electrical system brand: SHNINDER/SIEMENS Pump: Gear pump Motor brand: SIEMENS Control panel: E21 Upper part segment: 1 total Bottom mold metal: 1 set Front supply part: 2 pcs In addition, the control panel includes an emergency stop button and a safety section. |

|

Number of adjusting bolts: four pieces Additional tools: a set (screw driver and nut wrench, wrench) Manual and diagram: presented in book form |

|

Rear panel control system

1. Block control panel 2. General alternating current motor control, frequency generator 3. High precision positioning 4. Work volume calculator 5. Hold/Decompression time adjustment

|

Delivery service:

Briefly about the equipment:

Examples of products that can be prepared using this device:

Based on 0 reviews

Be the first to review “Hydraulic CNC metal sheet bending (listogib) equipment (80T/2500)” Cancel reply

Related products

-

Metalworking equipment

AF-M7 Metal pipe engraving machine

0 out of 5(0)Metal pipe embossing equipment is used for making beautiful embossing on any metal pipe. The equipment has simple operation, high production efficiency, stable forming effect and other features.

Pipe materials: stainless steel/copper/carbon steel/iron/galvanized/aluminum etc.

Pipe shape: Round and other shapes.

Application: Pipes designed for furniture, construction and other industries.

SKU: n/a11,800$ -

Metalworking equipment

Metal door production line

0 out of 5(0)Doors, including steel doors and gates, are always in demand. Modern polished steel doors and gates represent an ever-necessary home component. Therefore, the production of steel doors in the world market, this type of activity is a promising business idea, although the competition in this field is relatively high. Almost everyone can organize this activity, because the production of doors is not a technologically difficult activity.

SKU: n/a323,500$ -

Metalworking equipment

AF-N7 Metal pipe winding tracer

0 out of 5(0)The advantages of the metal pipe wrapping machine are: simple operation, high production efficiency, stable forming effect, high speed and other features.

Pipe materials: stainless steel/copper/carbon steel/iron/galvanized/aluminum etc.

Application: Pipes designed for furniture, construction and other industries.

SKU: n/a11,900$ -

Metalworking equipment, Other equipment

Leather belt production line

0 out of 5(0)Most of the leather belts are imported products. That is why we believe that the production of this product in the territory of our country will give you good results. We first need raw leather or a leather substitute to make the product. 10 types of equipment are involved in the production process, and our company recommends these equipments to you at the most reasonable prices.

SKU: n/a25,700$

There are no reviews yet.