Kitchen sponge production equipment

Out of stock

We will continue to recommend profitable businesses and high-quality production technologies for clients of “AFEX-GROUP”! Kitchen sponge production business is considered one of the businesses to satisfy continuous market demand. Today, in the production of kitchen sponges, the most modern materials with an increased level of usability are used. The variety of sponges is divided into categories. For example: metal sponges for removing burnt food. Foaming soft sponges for cleaning glassware, furniture, tiles, stoves and other types of dishes. There are different types of foaming sponges. In stores and markets, you will find different types of foam and synthetic fiber sponges, which differ in their external design.

19,800$

Out of stock

Cooking a kitchen sponge is a step-by-step, technologically uncomplicated process. You can make this product at home. The main component is abrasive synthetic fiber of the required thickness and small or large foam foam. The product that we recommend to you, when interacting with the foam cleaner, releases foam and cleans the abrasive fibers. This is the most effective way to clean dishes. In our daily life, we often do not pay attention to the quality level when buying this product. Product quality saves you time and water.

In the production of quality products, we offer you technologies for the production of synthetic fiber sponges with a level of serviceability and a beautiful external design.

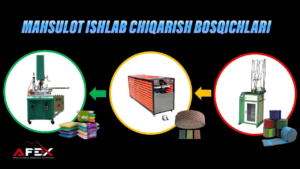

Let’s get acquainted with the production technologies of the product.

The equipment we need.

1)Nylon fabric weaving machine.

2) Equipment for applying foam to fabric.

3) Ultrasonic cutting equipment.

4) Air compressor

1)Nylon fabric weaving machine.

With this machine, you can weave wire and synthetic abrasive fibers. You can weave different types of ornaments and decorative flowers on the fabric. This weaving machine is able to weave 17-20 meters of finished fabric in one hour. The diameter of the woven fabric is 102mm. For continuous production of sponges, high-level automatic, touch screen control, can store 10 different kinds of formulas for weaving fabrics, and adjust the formula at any time.

⚠️Note; In order to increase production volume, you can purchase additional weaving machines. This does not affect the production capacity of other equipment.

| Nylon fabric spinning machine | |

| Power | 0,55 kw/ 220v |

| Control panel | PLC |

| Work speed | 17-20 m/h |

| Filling diameter | 102mm |

| Size | 450*500*800mm |

| Weight | 260kg |

With the help of a weaving machine, we send the finished fabrics to the next equipment.

2) Equipment for applying foam to fabric.

Applying foam to fabric – this stage is performed using equipment that is technologically less complicated than manual work, but with high efficiency. The machine places the cut-to-size foam into the fabric.

⚠️Note; This equipment is based on a pneumatic mechanism, that is, it works with the help of a compressor. There are electric versions of this equipment, if you want to buy the electric version it will cost you $1,000 less than the total listed amount.

| Palaron weaving equipment | |

| Power | 3kw/380v |

| Management system | Pneumatic control |

| I/O speed | 130m/h |

| Size | 2700*800*1200mm |

| Weight | 300kg |

We send the semi-finished products prepared using the equipment to the next equipment.

3) Ultrasonic cutting equipment.

The equipment automatically welds and cuts the sponges to size. With the help of a computer control system, you can produce products in the required dimensions. You can put the finished product for sale in markets and stores in bundles of 3-5 pieces, tied with the name of your company.

| Ultrasonic cutting equipment | |

| Ultrasound power | 3200w |

| Power supply | AC 110/220 |

| Welding field | Diametr 250mm |

| Production efficiency | 3000-4000 pc/h |

| The length of the sponge | 80mm-150mm |

| The width of the sponge | 60mm-110mm |

| The thickness of the sponge | 10mm-50mm |

| Time to weld | 0,01-9,99s |

| Time to wait | 0,01-9.99 s |

| It’s time to be late | 0.01-9.99s |

| Size | 1500*800*1900mm |

| Weight | 380kg |

4) Air compressor.

Air compressor; An auxiliary device is considered to be the equipment for foaming the foam and the ultrasonic cutting equipment.

| Compressor | |

| Voltage | 220v/50hz |

| Power | 0,78*3kw |

| I can | 70l |

| Maximum pressure | 7bar |

| Size | 900*360*735mm |

| Weight | 65 kg |

There are no reviews yet.