Paper bag production equipment (with 2 different color printers)

Out of stock

AFX-B330 paper bag making machine is environmentally friendly paper bags, which can be used as food paper bags and raw material paper bags.

155,000$

Out of stock

Of course, due to the growing demand for paper bags in our country, Afex Group wants to present you with another excellent production line. This production line is a very efficient and profitable business, because if this business is organized properly, it will definitely be successful in a short period of time. You will have to make an initial investment to start this production, but in 1.5-2 years you will definitely be able to cover this investment.

Here are some of the advantages of this production line:

- The fact that the product has a wide range;

- High demand for manufactured products;

- Raw materials are cheap and can be found in our country;

- Cooperation with large trade and industrial enterprises;

- High demand in fast food chains.

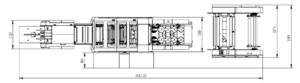

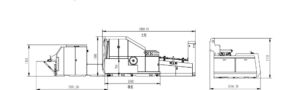

This equipment consists of paper bag side-to-side gluing, tube forming, tube cutting, , bottom gluing and package assembling. The whole machine is equipped with Japanese YASKAVA electronic control system, high speed can be achieved by servo motor. Equipped with high-precision photoelectric sensors, strong stability, simple maintenance, production efficiency are all combined in this equipment.

| AF-B330 paper production equipment | |

| Paper package length (cut length) | 280-530mm |

| Paper package width | 150-330mm |

| The width of the bottom part of the paper package | 70-180mm |

| Paper thickness | 60-150g/m2 |

| The width of the paper roll | 470-1050mm |

| Roll paper diameter | 1300 mm |

| The maximum speed of the equipment | 220pcs/minute |

| Paper package rotation speed | 180-200pcs/minute |

| Hardware power | 380V 3 phase 4 line 8kw |

| Equipment weight | 8000 kg |

| Equipment dimensions | 9500*2600*1900 mm |

External dimensions: 9500*2600*1900mm

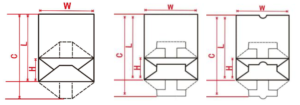

W: paper package width

C: the length of the bottom part of the paper package

L: paper package height

H: the width of the bottom part of the paper package

Automatic correction system, the system is mainly to ensure the smoothness and stability of the web paper position.

The part that forms the bottom part of the paper package

The part connecting the bottom part of the paper package

The formed paper package is pressed together and released. The bagging device can set automatic counting when the finished product exits the equipment according to the requirements.

| Materials and technical process of the main equipment | |

| Main outer material | Cast iron QT400 |

| Gear material | 38CrMnAl |

| Handle material | 45, 40 Cr |

| Other materials | ZG270-500, G12MOV |

| The thickness of the shaft between the layers | >0.08mm |

| The surface thickness of the drive gear | 45-50 HRC |

| Materials of fastening screws | 45# steel grade 12 |

| Conveyor belt material | Switzerland Habasit |

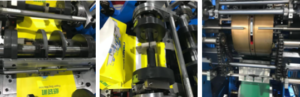

Two color printer equipment (optional)

1. Control units

1.1: Basic machine control by transducer (converter).

1.2: The gear motor sends ink separately with two sets of rollers

2. printed parts

2.1: Pneumatic lifting and lowering printing plate cylinders, automatic lifting plate cylinders are activated when the machine is stopped. After that, the ink can be activated automatically. When the machine is opened, it signals the automatic unloading plate to start the printing cylinder.

2.2.: Ceramic anilox chamber doctor knife painting, ink pump cycle 2.3. High-precision oven 360 ° rotation longitudinal register

2.4. ±20 mm transverse register.

3: Drying part

3.1: External heating tube, temperature indicator, electric current control, centrifugal fan wind drying.

| AFX-LT2-800-1400 printer hardware | |

| Maximum copier width | 800mm-1400mm |

| Maximum copy width | 760 mm |

| Print length range | 230-800mm |

| Copy speed | 5-100m/minute |

| Accuracy of equipment operation | <+0.20mm |

| Line parts | |

| Name | Price |

| AF-B330 main production line | 124 000$ |

| Two color printer (optional) | 31 000$ |

| Total cost | 155 000$ |

There are no reviews yet.