Asphalt production plant

Out of stock

Buildings and structures are a symbol of the power of each country. The perfection and quality of buildings and roads greatly contribute to the reputation of the country. In recent years, positive changes have been taking place in this field in our country.

One of the main problems in our country is that most roads do not meet quality standards. This can be attributed to various factors. Our company offers you, dear customers, a mini factory for the production of asphalt, one of the main construction products. We hope that you can produce quality and affordable products through this factory.

383,900$

Out of stock

Advantages

- Safe – asphalt pavements provide high speed resistance, provide high color contrast between the asphalt pavement and road markings, and provide drivers with a good view of the road in all weather conditions. Asphalt roads melt ice and snow faster than other roads.

- Smooth – asphalt pavements provide a smoother surface than other pavements. Because asphalt is softer, it reduces tire wear, which means better fuel economy and lower carbon dioxide emissions.

- Noiseless – Asphalt roads can reduce road noise by up to seven decibels. For reference, it should be mentioned that reducing the noise by only three decibels is equivalent to doubling the distance between the noise source and the listener.

- Environmentally friendly – asphalt is a 100% recyclable product. Asphalt requires 20% less energy to produce and build than other pavement materials. After consumption, used tires and other petroleum products can be reused in new asphalt pavement, thus saving natural resources.

- Durable – asphalt pavements are durable for a long time. All asphalt pavements are cohesive and flexible. This increases their scope and capabilities.

The main parts of the plant

Below you can see the main production parts of the factory:

- Raw material delivery system

- Raw material drying-heating system

- Raw material mixing system

- Pneumatic pressure system

- Central control system

- Dust removal system (wet dust)

- Mineral powder storage and delivery system

- Asphalt heating system (energy efficient)

General information

Now let’s get acquainted with more detailed information about this mini factory. Below you can familiarize yourself with the general technical indicators of the plant:

- Production capacity: 60 tons/hour

- Hot asphalt temperature: 130°C-165°C

- Operating noise: ≤70 db(A)

- Process control: Manual and fully automatic

- Voltage: 380V, 50Hz

- Power: 135.84kw

- Plant dimensions: 36*18*13 m

- Required area: 650 square meters

- Raw materials: carbon, nitrogen, sulfate, hydrogen, nickel, metal and other oil residues, coal, water, mineral stones.

- Types of asphalt: hot and cold

One piece of information should be mentioned here. With this line, two different types of asphalt can be produced. Therefore, there will be changes in the chemical composition of the asphalt. Depending on the characteristics of the asphalt and the desired density, the plant can be adjusted. Now we can move on to the necessary equipment and processes.

Raw material delivery system

The first step in production is to store the necessary raw materials and supply them to the next equipment. So, for this we need a raw material storage tank. This plant has 4 such tankers. This means that 4 different raw materials can be stored. According to the customer’s request, tankers are added for an additional fee.

| Storage tanks | |

| Capacity | 4*6.5 m3 |

| Loading height | 3 m |

| Width | 3.2 m |

| Motor power | 4*1.5kw |

| Belt width | 500 mm |

| Vibration motor power | 2*0.25kw |

Next, we need two types of conveyors (TK-35 AND TK-45). Their task is to collect raw materials from tankers and deliver them to the next equipment.

| TK-35 | |

| Belt width | 500mm |

| Capacity | 80 tons/hour |

| Power | 4kw |

| TK-45 | |

| Belt width | 500mm |

| Capacity | 80 tons/hour |

| Power | 5,5kw |

Raw materials may contain various wastes and excess small stones. Therefore, we place a screen (screening equipment) between two conveyors.

Raw material drying-heating system

Now it’s time to heat the ingredients. Burning them at a high temperature leads to high quality. First of all, you need a cylinder drum divided into three parts to heat them. The temperature inside the cylinder drum is around 400-500 degrees.

| Cylinder barbara | |

| Diametr | F1,2m |

| Length | 5,2m |

| Motor power | 11kw |

| Capacity | 80 tonn/h |

We also need equipment for burning coal. This plant of ours is adapted to work on coal, taking into account the latest situations. This equipment includes a coal crusher. On average, 13-15 kg of coal is needed to produce 1 ton of product. The equipment consumes a total of 45kw of electricity.

Lifting equipment

Our factory includes two elevators. The first is to raise the aggregate that has reached the state of mixture. The second one picks up the powdery raw materials left over from the aggregates. You can understand this in detail from the video at the end of the post.

Screening system

So, we took the aggregates, which are finished products, up. At the next stage, we will use the 4-layer vibrator equipment. This equipment separates the aggregates from each other with the help of shaking and sieves of different sizes. The motor power of the equipment is 7.5kw.

Measuring system

In the previous stages, we separated the aggregates using a vibrating screen. At this stage, we can separate them from each other and measure them. For this we need 3 measuring containers: for hot aggregate, for raw materials in powder state and for measuring asphalt. 3 sensors are placed in each of them and have capacities of 700kg, 80kg and 50kg, respectively.

Mixing system

We have reached the most important part of our production process – mixing of products. Proper mixing of semi-finished raw materials has a great impact on the quality of our final product, asphalt. For this we need the following equipment

| Mixer | |

| Mixing capacity | 700kg |

| Duration of mixing | <48s |

| Motor power | 30kw |

| Number of compartments | 4 ta |

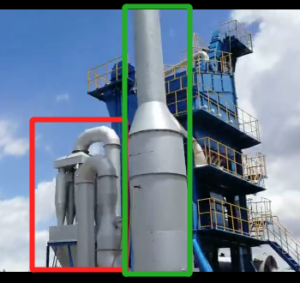

Dust removal system

This system requires the equipment in the pictures below.

The part inside the red frame is the cyclone dust removal equipment. The green part is the water filter cleaning equipment.

Transport and storage system

In the production process, raw materials are also brought to a powder state. because asphalt in the powder state is also added to hot asphalt when repairing roads. For this we need two silos and a conveyor. You can find out what kind of powder it is through the video in the last part.

Tankers, bunkers and pumps are also needed for transportation and storage of ready-made asphalt.

Pneumatic pressure system

For this we need one air compressor and its other spare parts. The capacity of the air compressor reaches 3 m3/min. The power is 7.5kw.

Management system

Our line includes a fully automated electronic control system. It includes:

|

|||||||||||||||

Through the video posted below, we present the production processes of the asphalt plant in an animated form.

| Prices | |

| Raw material delivery system | 383 900$ |

| Raw material drying system | |

| Lifting equipment | |

| Screening system | |

| Measuring system | |

| Measuring system | |

| Mixing system | |

| Dust removal system | |

| Transport and storage system | |

| Pneumatic pressure system | |

| Management system | |

There are no reviews yet.