Adhesive tape (scotch tape) production line

Out of stock

About the product in brief:

“SCOTCH” in common languages, despite the English name Scotch – Scotland, was first created in Germany. Duct tape was originally made of gauze and was patented in 1882 to Paul Karl Beiersdoff. Pharmacist Oskar Troplowitz, who worked at Beiersdorf AG at that time, improved it in 1901 and named it LEUKOPLAST. Later, the adhesive tape produced by Scotsman Dick Drew in 1925 was called “SCOTCH” (English scotch – Scotland).

68,700$

Out of stock

Adhesive tape is one of the widely used products mainly in stationery, packaging, enterprises and organizations, construction, schools, offices and other fields.

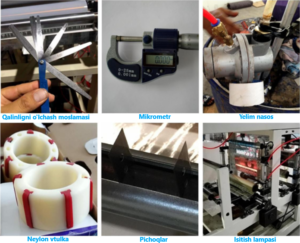

Required raw materials:

1) Polymer BOPP film.

2) Glue.

3) Cardboard.

The quality of the product depends on the quality of the raw materials. The basis of the adhesive tape is a polymer film. It can be of different thickness. Standard thicknesses start at 30 microns. Therefore, it should be chosen depending on the type of adhesive tape to be made.

Another important component of scotch tape is glue. Usually (Acrylic glue) water-based adhesives are used. Other types can give off a specific smell, which is generally not liked by the consumer.

Cardboard should be bought the most durable, because it is the basis and should not be deformed.

Sales:

Product sales do not depend on the season. Customers are in demand for colored, decorated, and sealed versions of adhesive tape for office use. You can meet customer demand by producing adhesive tapes with the logo of major manufacturers and selling companies. It’s best to start with the most standard sizes with 45-48 mm wide adhesive tape, then you can expand gradually. On sale, you can find adhesive tapes of various widths that are in demand by customers.

Required field:

All equipment of the production line can be placed on an area of 150 square meters. The minimum height of the ceiling should be above 3 meters. Having all the equipment in one place ensures the production of many products with less workers. The number of workers requires 3-4 people.

Taking into account the budget and product sales of entrepreneurs, we provide a small but short-term multi-product production line for the customers of the “AFEX GROUP” team!

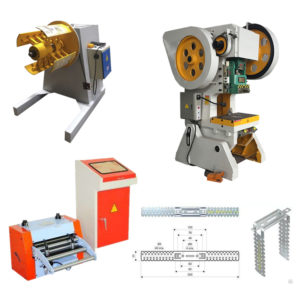

Line tracking equipment:

1) Equipment for cutting roll papers to size

2) Paper tube making equipment

3) Cut paper tubes to size

4) Equipment for installation of size pipes and extraction of finished products

5) Polymer film gluing and coloring equipment

6) Equipment for wrapping glued tapes in sizes

7) Roll length measuring equipment

The total production capacity of the line is 20-30 meters/min (width 500mm). That is, 10 pieces/min of scotch tape with a width of 50 mm and a length of 30 meters.

1) Equipment for cutting roll papers to size

Equipment conveniences; Speed regulation, upper and lower blades adjustment in the range of 20-1600 mm, pneumatic paper expansion or tension are all placed on the control panel.

| Technical indicators | |

| Paper width | 1600mm |

| Paper diameter | 1200mm |

| Cutting width | 40mm |

| Cutting speed (min) | 200m |

| Cutting knives | 25 |

| Power | 5kw |

| Equipment dimensions | 2200*2200*1600mm |

| Weight | 1000kg |

This equipment cuts the paper rolls to size. The paper cut to size is sent for pipe making.

2) Paper tube equipment.

A paper tube is made from glue and paper using equipment. The equipment is low-noise, all functions can be adjusted on the control panel, and it has the convenience of automatic cutting of the specified length.

| Technical indicators | |

| I/O speed | 1-8m/min |

| Gluing method | 1-2 servings |

| Paper fold diameter | 15-100mm |

| Orash layer | 3-13 layers |

| Management system | Computer PLC |

| Equipment size | 2900*1800*1600mm |

| Weight | 2000 kg |

We send the pipes ready in the equipment to the size cutting equipment.

3) Cut paper tubes to size

The equipment cuts the paper tubes to the specified dimensions using a circular disc. The cut pipes are pushed out using a pneumatic (compressor) cylinder. We send the size pipes to the equipment for installation and extraction of finished products.

| Technical indicators | |

| Minimum cut | 12mm |

| Pipe diameter | 76,2mm |

| Air pressure | 0,5mpa |

| Working speed | 30m/min |

| Power | 2,2kw |

| Dimensions | 1500*600*1000mm |

| Weight | 200kg |

4) Equipment for installation of size pipes and extraction of finished products

The equipment has the ability to automatically install pipes of size and remove finished products. This equipment also works with a pneumatic (compressor) cylinder.

| Technical indicators | |

| Pipe diameter | 25,4-76,2 mm |

| Air pressure | 5mpa |

| Dimensions | 2800*800*1350mm |

| Weight | 120kg |

5) Polymer film gluing and coloring equipment

Polymer Bopp uses a printer to print transparent, printed, colored, patterned, and logo tapes (two colors are provided in this equipment). A layer of acrylic glue is applied to the equipment and dried in a drying oven at a temperature of 70-90 degrees. The product coming out of the oven is wound on reels.

(You have 2 options either to roll it into a large package and then cut it to size or connect it directly to the cut to size equipment for the finished product.)

| Technical indicators | |

| I/O speed | 20-30min/m |

| The width of the colypes | 500mm |

| Gluing method | 1-2 servings |

| Cogozkatlam diameter | 15-100mm |

| Orash layer | 3-13 layers |

| Management system | Computer pls |

| Print out | two-color printing |

| The length of the oven | 6m |

| Power | 3faz, 380v,50hz |

| Dimensions | 8,1*1,6*2,6 m |

| Weight | 2000 kg |

6) Equipment for wrapping glued tapes in sizes

This equipment has a total of 8 shafts, 4 large shafts and 4 small shafts.

| Technical indicators | |

| I/O speed | 120/min |

| Cutting width | 500 mm max |

| Cutting width | 10mm min |

| Management system | Computer plc |

| Power | 4kw max |

| Tension | 3faz, 380v,50hz |

| Dimensions | 1,6*1,3*1,35 m |

| Weight | 1000 kg |

7) Roll length measuring equipment.

The equipment is used to measure package lengths and rewrap poor quality packaged products.

| Technical indicators | |

| I/O speed | 50-100 m/min |

| Roll diameter | 200 mm max |

| Power | 0,2 kw |

| Dimensions | 500*450*650 mm |

| Weight | 50 kg |

There are no reviews yet.