Ultrasonic welding and sewing equipment AF-L020

Out of stock

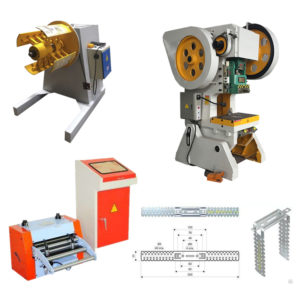

As our time progresses, innovations are rapidly entering every field. Including in the field of textiles, innovations with somewhat economical and convenient solutions are taking place in our lives. The equipment that AFEX-GROUP LLC recommends to you today is the ultrasonic welding equipment, which has been serving to decorate our imported products with various shapes for 3-4 years. This equipment differs from the equipment of its previous generation with a number of advantages. At present, baked products are very popular in our country and in the world. For the production of these forged products, traditional bending machines and modern bending machines are used. Traditional looms do the stitching using yarn, and this manufacturing process is not without some drawbacks. Below we will compare the new ultrasonic and traditional threading.

29,000$

Out of stock

Spinning equipment requires constant monitoring and maintenance costs are high. (Needles, servo motor, inverter, etc.)

The bending speed is low, taking into account the consumed electrical energy, the useful work coefficient is not high.

The type of motor to be welded and its thickness must be constantly monitored, otherwise this mistake can cost you dearly.

The cost of the equipment

Excessive noise during operation

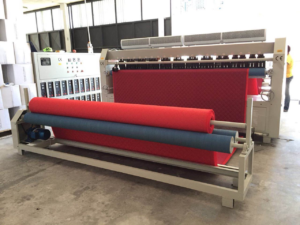

We offer you a new and up-to-date ultrasonic welding machine and, in addition, an ultrasonic sewing machine. What amenities does the line we recommend have?

The cost of the output will be significantly reduced

Due to the high speed, orders are fulfilled on time

Since the bending is done through a special mold, the equipment costs are relatively cheap. The most important thing is that no thread is used during the weaving process.

We also recommend ultrasonic sewing equipment to sew the edges of your product to minimize your costs. You can do many other things with this equipment.

Artificial leather products can also be used

Even after many washes, the quality of the curl remains unchanged

You can produce 2-layer (fabric+sintepon) and 3-layer (fabric+sintepon+fabric) products with the help of the sewing equipment we recommend. Below you can familiarize yourself with the technical specifications of the equipment.

| Produced | China |

| Voltage | 380v50hz |

| Power consumption | 1.5KW-5KW+0.75KW-2KW+0.75KW |

| Ultrasound generator | 600w* (6-20 units) |

| Fabric width (fold width) | 2200 mm |

| Size | 7000x2700x2100(LxWxH)3T |

| Weight | 0-400m/h |

| Speed of operation | 20 kHz |

The AFEX-GROUP team will not spare its advice to our entrepreneurs who want to start work in this field, how to start this work on their own, where to get the necessary raw materials, whether there is a specialist to start the work, and we have qualified specialists. We can produce products that are currently popular in our markets, such as blankets, pillows, outerwear, car seat covers, etc. Below are some samples of products for your attention.

You can also use a regular sewing machine for the edges of your product, but we recommend an ultrasonic sewing machine. Thread is not necessary for this equipment, and the appearance of your product will also be dramatically different from others. By choosing the appropriate rollers, you can make the border with different floral patterns. In this case, the frequencies are given to the desired point and the situation is like welding. In this case, it is convenient for ready-made products in the form of fabric + sintepon + fabric, and the fabric itself can also be used.

With the help of the two equipment offered to you above, you can produce many products that are popular in the market of our country. We have worked hard for your business development because you are not limited to the same product and the cost of your products is slightly cheaper than other similar product providers and you have few competitors so far. We think that the business that we offered you today was good.

There are no reviews yet.