Shovel (shovel) production line

Out of stock

Hello, dear customers of AFEX-GROUP. There is a saying in our people: “If your work tool is good, your work will be less”. We can see how true this saying is throughout our lives. Due to the arrival of spring in our country, we would like to inform you about the production of shovels, which are one of the most used working tools by our people in this season. Below you can get acquainted with a set of equipment needed for production, production process sheets and sketches of a shovel.

44,900$

Out of stock

General information

- Production Name: Shovel Production

- Production volume: 40 units/hour on average (depending on the size)

- Production capacity: 40kw/h

- Required area: 60 square meters

- Special requirements: Protection against water and dust, availability of 380V electric current at the installation location.

- Number of workers: 2

- A set of equipment

The complete set includes the following equipment:

- Automatic press equipment

- Special molds

- Wood rounding equipment

- Handle polishing equipment

- Tool for ovalizing the handle

- Automatic press equipment

So, the equipment we need in the first place is automatic press lab equipment. With the help of the equipment, you can make the specially cut metal parts into different shapes using molds. At this point, it is necessary to pay attention to one piece of information. 3 different molds can be used in the equipment.

| Automatic pressing equipment | |

| Nominal pressure | 1600KN |

| Max hydraulic pressure | 25 MPa |

| Desktop size | 720*620mm |

| Main power | 11kw |

| Equipment dimensions | 2800*1500*3400 mm |

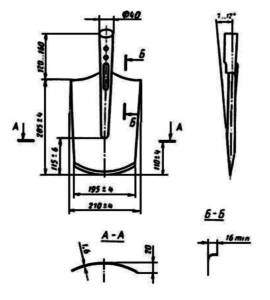

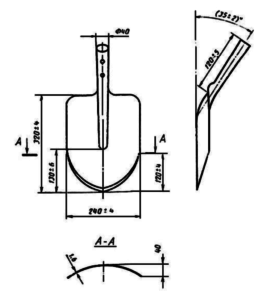

The task of the first mold is to cut a shovel part from rectangular metal. After cutting, the metal looks like this.

With the help of the second mold, we can now bend the cut metals.

The handle input end of the metal part is fixed with the help of the third mold.

With this, the metal part of our shovel is ready. If you noticed, during the production process, we used one press equipment, we only changed the molds. If you want to increase the volume of production, it is better to get 3 press equipment for 3 molds.

In the drawings below, you can see drawings for the production of shovels of various shapes.

Wood rounding equipment

So, first of all, we need the above equipment for woodworking. The task of this equipment is to bring the rectangular logs to the diameters we need. Let’s consider the technical indicators of the equipment:

| Wood rounding equipment | |

| Voltage | 380V50Hz |

| Main motor power | 4kw |

| Additional motor power | 0.75kw |

| Number of blades | 2 |

| Production speed | 5m/min |

| The wood is diametric | 20-60mm |

| Min length of wood | 500mm |

| Equipment dimensions | 1470*590*1000mm |

| Weight | 520 kg |

You can see footage from the production process in the following video:

Handle polishing equipment

At the next stage, we process the upper part of the handles, that is, we polish them. By polishing, we beautify our handles, make them easier to grip and are considered to prevent various injuries (removes nicks). Film from the production process

| Polishing equipment | |

| Voltage | 380V50Hz |

| Main motor power | 2.2kw |

| Additional motor power | 0.44kw |

| Speed of operation | 5-10m/min |

| Grinding diametric | 10-60m/min |

| General dimensions | 800*700*1350mm |

| Weight | 210 kg |

Tool for making the end of the handle oval

In order to make it convenient to work with our shovel and not to cause harm and discomfort to the hands during work, we should make the handles of the shovel oval. Oval shaping also requires separate equipment.

| Oval forming equipment | |

| Working diameter range | 20-40mm |

| Spindle speed | 5000r/min |

| Motor power | 1.5kw |

| General dimensions | 720*560*820mm |

| Net weight | 130 kg |

Based on 0 reviews

Show reviews in all languages (1)

Be the first to review “Shovel (shovel) production line” Cancel reply

Related products

-

Metalworking equipment

AF-M8 Marking equipment for metal pipes

0 out of 5(0)Metal pipe embossing equipment is used for making beautiful embossing on any metal pipe. The equipment has simple operation, high production efficiency, stable forming effect and other features.

Pipe materials: stainless steel/copper/carbon steel/iron/galvanized/aluminum etc.

Pipe shape: Round and other shapes.

Application: Pipes designed for furniture, construction and other industries.

SKU: n/a28,000$ -

Metalworking equipment

AF-N7 Metal pipe winding tracer

0 out of 5(0)The advantages of the metal pipe wrapping machine are: simple operation, high production efficiency, stable forming effect, high speed and other features.

Pipe materials: stainless steel/copper/carbon steel/iron/galvanized/aluminum etc.

Application: Pipes designed for furniture, construction and other industries.

SKU: n/a11,900$ -

Metalworking equipment, Solution product lines

Production line of PU insulating decor products for walls

Metalworking equipment, Solution product lines

Metalworking equipment, Solution product linesProduction line of PU insulating decor products for walls

0 out of 5(0)This production line:

The whole line adopts the first line brand touch screen, sine frequency converter. Features: Real-time monitoring and data display of the entire line; The equipment is easy to use, can do start and pause, automatic and manual mode change.

SKU: n/a237,000$

There are no reviews yet.