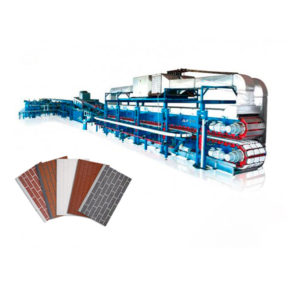

Spunbond production line

Out of stock

About the product in brief:

Spunbond is a non-woven fabric production technology. Later, this term began to be called the name of the fabric produced by this technology.

398,400$

Out of stock

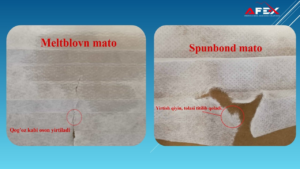

First, let’s distinguish Spunbond fabric from other non-woven fabrics. These fabrics, which are usually similar to each other, differ in their names and production methods. The most common types of non-woven fabrics are Cellulose, Meltblown, and Spunbond. can be visually distinguished in these pictures.

Although our main topic is Spunbond fabric and production technologies, we will touch briefly on Cellulose fabric and Meltblown fabric. The reason is that the demand for these products is high.

Cellulose fabric

Cellulose non-woven fabric; The raw material is mainly PP+Paper. In order to improve the quality level, for example, viscose, cotton, PET and other additional composites can be added.

Application: You can see it mostly in baby diapers (Pampers), sanitary napkins. Cosmetology, medical services, small towels, napkins, alcohol tampons and other fields are also widely used.

Meltblown fabric

Meltblown Nonwoven Fabric – Meltblown (meltblowing) is a traditional method of producing microfibers and nanofibers in which a polypropylene (PP) melt is blown through high-velocity hot air to extract micro and nanofibers.

Application: It is mainly used for oil products, water, air filtration, respiratory protection, medical masks, medical clothes, baby diapers, antibacterial non-woven fabric against dust and bacteria.

The “AFEX GROUP” team also offers the services of supplying and installing lines for the production of cellulose fabric and meltblown fabric for its customers with the help of qualified technologists.

To distinguish spunbond fabric from other non-woven fabrics, we can identify spunbond and meltblown fabrics with easy and simple tests.

Meltblown fabrics are easy to tear like paper. Spunbond fabrics are difficult to tear, and after tearing, you can see in the picture that they are like cotton fibers.

Meltblown burns quickly and leaves less waste. Spunbond fabrics turn into plastic waste during burning.

Another easy way to identify and differentiate is to use a medical mask (original).

We have distinguished SPUNBOND fabric from other non-woven fabrics. Now we will get acquainted with the information and production technologies of Spunbond fabric.

SPUNBOND-Synthetic fiber combined non-woven fabric. SPUNBOND continues to be promising in the world market with a high growth rate compared to textile fabrics. The last year of 2020 (also due to covid-19) this fabric The demand has increased even more.

• Environmentally friendly.

• Does not combine with chemicals.

• Does not emit dangerous substances.

• Low flammability.

•Temperature resistant -55°C +120°C.

•Retains dryness and moisture.

Application:

Spunbond is one of the widely used products in medical masks, special medical clothes, bags, shoes, product packaging, furniture, road construction, agriculture, sun protection of horticultural products, construction and other fields.

Required raw materials:

1) Polypropylene (PP) is a thermoplastic polymer of prolylene.

2) Polyethylene terephthalate – thermoplastic polyesters.

3) Polyamides – plastics based on synthetic compounds.

Polypropylene (PP) is mainly used as a raw material for the production of spunbond fabrics, because it provides the most dense distribution of combined synthetic fibers and the production of high-quality fibers per kilogram of raw materials.

Types of product density:

Product density varies from 15 g/m² to 600 g/m². This parameter is determined depending on the desired goals. Spunbond with a density of 15 g/m² is used for sewing disposable clothes and other products, and from 120 g/m² is used as a variety of fabrics and agrotextile fabric.

In the market, you can see products of this brand type.

•S- Spunbond

•SS- Spunbond+Spunbond

•SMS- Spunbond+Meltblown+Spunbond

• FAQ- Spunbond+Spunbond+Spunbond

These trademarks identify the fabric layer.

Sales:

The demand for non-woven fabrics is increasing both in the world market and in the markets of our country. A significant part of the goods is bought by wholesale trade enterprises and sewing factories. The remaining parts are bought for use in agriculture and road repair. you can get

Business plan:

From the manufactured SPUNBOND fabric, you can make the following finished products.

• Special medical clothes

• Bag of clothes

• Disposable footwear

• A bag of blankets and sheets

• Special bags

Required field:

The total size of the equipment is 30×12 meters. The height of the ceiling should not be less than 12 meters. There should be a building with an area of at least 1500 square meters to accommodate the equipment, raw materials and finished products. The building also includes crane equipment and light trucks. there must be ways out.

Required supplies:

All elements of the infrastructure of the industrial facility must be provided with electricity, water supply, (gas).

• Line power – 250 KW/380V, 50HZ.

•Required transformer-above 400KW/380V, 50HZ.

• For 1 ton of product – 400 KW energy consumption.

• Amount of water circulation – 100 m3 / hour.

• The amount of water filling is 0.5 m3 / hour.

• The number of workers requires 5-8 people.

Production mechanism:

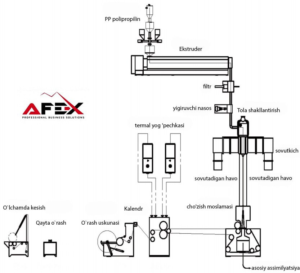

The process of forming synthetic fiber (S line) includes the following main stages:

1) Preparation of polymer raw materials and delivery to the melter.

2) Polymer dissolution and solution filtration.

3) Giving the solution to the spinning set.

4) Fiber formation.

5) Aerodynamic drawing and air cooling of fibers.

6) Laying fiber on the conveyor for the production of synthetic fabric.

7) Calendering and wrapping the resulting synthetic fabric.

We have also familiarized ourselves with the production mechanism and all the necessary information.

Line tracking equipment and devices

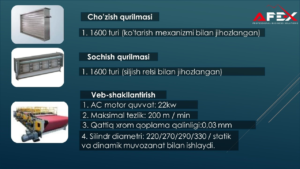

I. Basic devices.

1) Automatic pitatel.

2) Main extruder.

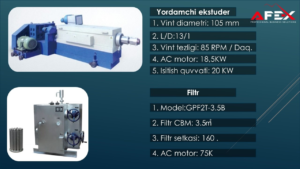

3) Auxiliary extruder.

4) Filter.

5) Spinning pump.

6) Fiber forming device.

7) Cooling system.

8) Stretching device.

9) Spraying device.

10) Web formation (special conveyor).

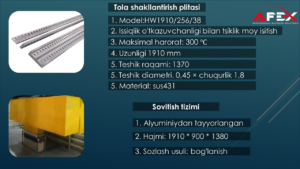

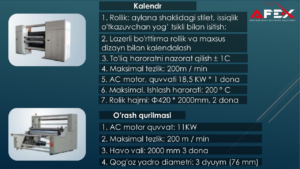

11) Calendar

12) Wrapping equipment.

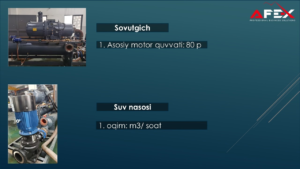

II. Auxiliary devices

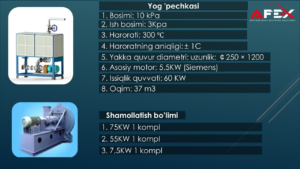

1) Oil stove.

2) Ventilation (ventilation) department.

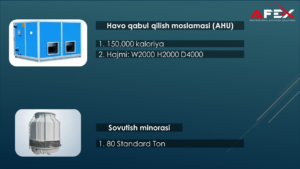

3) Air intake device.

4) Cooling tower.

5) Refrigerator.

6) Water pump.

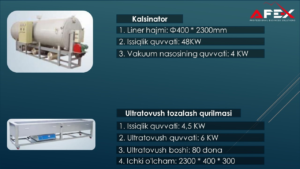

7) Calcinator.

8) Ultrasonic cleaning.

9) Oil tank.

10) Cart for fabric.

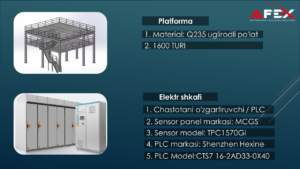

11) Platform.

12) Electric cabinet.

•The capacity of the line is 1600mm wide, it produces products with a density of 15-200 grams/m2. The production speed is 150-180 meters per minute for a product with a density of 15 grams.

Necessary information on the technical indicators of the equipment and devices on the line.

With the help of an automatic pitatel, polypropylene products are taken from a special container and supplied to the extruder with enough raw materials for melting. The extruder sends the raw materials to be melted and filtered at a temperature of up to 250 degrees.

The auxiliary extruder is used for the processing of defective and low-quality products. The filtering device is one of the important parts in the quality production of products.

The melted raw material is spun into yarn after the filtering device by the spinning pump.

The formed plastic fibers are cooled with cold air in the cooling system. The cooled fibers are sent to the stretching device.

The stretching device puts the cooled fibers into a thin long shape and compacts them together. Condensed 1600mm fibers are continuously placed on a special conveyor for web formation with the help of a spreading device.

In the calendering equipment, the formed fibers are given special shapes with the help of rollers at a temperature of 200 degrees in the calendering equipment.

Oil stove heats oil for calender equipment at 200 degree heat. Main motors in ventilation section.

Cooling This device supplies cold air to the fiber forming cooling system. The amount of water circulation is 100m3/h.

There are no reviews yet.