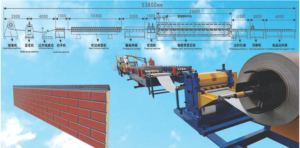

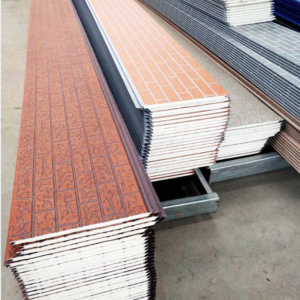

Production line of PU insulating decor products for walls

Out of stock

This production line:

The whole line adopts the first line brand touch screen, sine frequency converter. Features: Real-time monitoring and data display of the entire line; The equipment is easy to use, can do start and pause, automatic and manual mode change.

237,000$

Out of stock

The length of the PU insulation decor production line for walls is about 54m, mainly consisting of winding machine, embossing machine, smoothing and grinding machine, molding machine, polyurethane grinding machine, back layer material rack, laminating machine, and cutting device, air It consists of a compressor (according to the customer’s proposal), a PLC control system and devices that supply the finished product.

Basic equipment and parameters of the production line

This equipment is manufactured using high quality 45# steel solid shaft conditioner, I steel, square pipe and steel plate welding, magnetic powder brake force expansion device. Features: the winding adopts passive traction type, equipped with a brake system to control the expansion force; There is a special design principle to get rid of plate embossing waste.

AUTOMATIC ROLL DISTRIBUTION EQUIPMENT:

| General dimensions | 2200*1000*1000mm |

| Supply part width | 600mm |

| Weight bearing capacity | 3 T |

| Cylinder diameter | 470mm-510mm |

| Expansion control panel | 400NM magnetic powder |

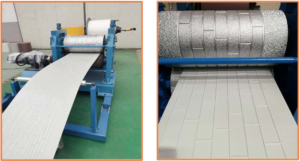

Embossing part

Structure: The frame is made of high-quality steel plate welding, the roller is made of high-quality 45# steel, the surface is tempered and chrome-plated, and it has a precision gear drive equipped with a brand frequency conversion motor. Features: CNC engraving machine and professional flower roller are carefully used by experts in hand engraving, color steel plate smooth, delicate pattern, precise layers, three-dimensional sense printing is the second level of the wall board. designed to provide color, and it certainly has a high aesthetic effect.

| General dimensions | 2200*800*1200mm |

| General dimensions | 310*600mm |

| Roller material | 45# steel |

| Roller surface | Tempered, chrome plated |

| Speed | 0-16 m/min |

| Engine power | 380V,50hz,4.0KW |

| Transmission mode | A gear that moves up and down |

| Pressure regulation | Screw pressure |

| Printed thickness | Color steel 0.2-0.5mm*500mm |

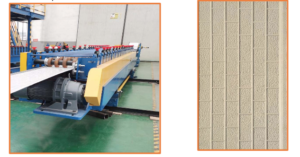

Angle forming machine

Structure form: The frame is welded with high-quality steel plates and H-BEAM steel. The spindle and roller are made of tempered heat treated 45# steel. Features: Development of multi-wheel flange form for embossing color steel;

| General dimensions | 7200mm*1050mm*1200mm |

| Color steel forming | 380mm*16mm |

| Speed | 0-10m/min |

| Roller forming | 18 |

| Roller material | Cr15 high quality steel processing, hard chrome plating |

| Spindle material | ⌀55mm 45# steel, pressed and hardened

|

| Gear shifter | 45# high quality steel |

| Engine power | 380V, 50Hz, 7.5KW |

Technical parameters for molding

| General dimensions | 7800mm*1050mm*1200mm |

| The part that forms the color of steel | 380mm*16mm |

| Speed | 0-10m/min |

| Roller shaper | 22 |

| Roller material | Cr15 high quality steel |

| Spindle material | ⌀55mm 45# steel, pressed and hardened

|

| Gear shifter | 45# high quality steel |

| Engine power | 380V, 50Hz, 7.5KW |

Roll wrapping platform

Structure: It has convenient opening machine and brake system.Features: special frame design is convenient to change coils, and two sets of aluminum foil unloading racks work alternately to improve working efficiency.

| General dimensions | 4000mm*1200*600mm |

| Wrapping material | Aluminum dice paper |

| Supply part width | 380mm*500mm*600mm |

| Extension control panel | Automatic braking system |

Mixer and spreader for polyurethane (PU) component A and B:

Structure form: heating tank, additional insulation layer; The top head is a fine mechanical seal device to ensure air flow during mixing; High precision gear metering pump; Using floating mechanical seal device, high shear spiral mixing head, uniform mixing of mixing head, no clogging with automatic cleaning system. Features: High injection precision, uniform mixing, stable performance, simple operation, high production efficiency.

| General dimensions | 1800mm*1500mm*2200mm |

| Control system | PLC control cable |

| Engine power | 380V,50Hz,7Kw |

| Injection pressure | 0.2-0.5 mpa |

| Injection current | 15-69g/S |

| A or B | 250L |

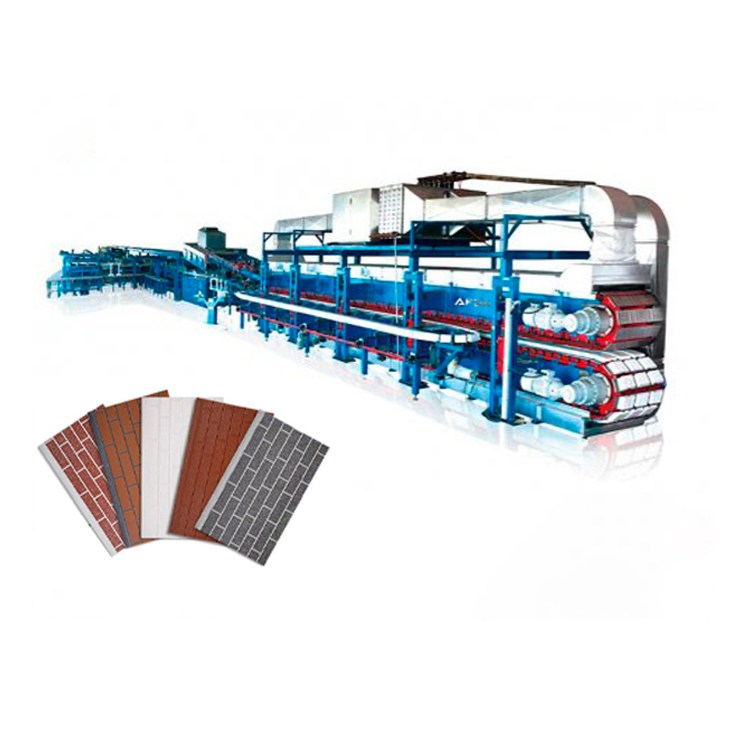

Rubber belt lamination equipment.

Structure form: The frame is made of high quality 30# channel steel and steel plate welded; There is a high-quality high-temperature rubber belt and a guide roller with precise power. Features: The upper and lower parts of the machine can be lifted synchronously, and the lamination is very stable and consistent. The outer wall of the laminating machine is equipped with an insulation board to ensure that the internal temperature is not lost and the wall board is smooth and beautiful; It has fast working speed, high level of automation, high production efficiency.

| General dimensions | 23000mm*1200mm*2800mm |

| Forming plate | 16*380mm (thickness and width) |

| Frame structure | 30# channel steel, no power guide

|

| Heating system | four automatic temperature control 0-60 ° C electric heating

|

| Laminated structure | Two layers of temperature-resistant rubber belt 0-60°C

|

| Supplier panel structure | Up and down synchronous gear transmission |

| Engine power | 380V, 50Hz, 7.5 KW , 6-12m/min |

| Full capacity of the equipment | 380V, 50Hz, 60 kw (includes heating power)Cutting equipment with servo system |

Structure form: The frame is welded by high quality steel plate and square tube. Adopt a pneumatic system device; A high-powered vacuum device is acceptable. Features: human-machine interaction and intelligent operation, control electric cabinet, servo motor tracking cutting device, cutting accuracy and stability are greatly improved;

| General dimensions | 2600mm*1600mm*1500mm |

| Hard plate | Pneumatic pressing |

| Cutting speed | 4000 rpm |

| Shear thickness | It can be changed automatically |

| Engine power | 380V, 50Hz, 6Kw |

PLC control electrical panel

/ PLC Structure: The whole line adopts first-line brand touch screen, sine frequency converter. Features: real-time monitoring and data display of the entire line; The equipment is easy to use, can do start and pause, automatic and manual mode change.

Samples of the finished product:

| Part names | Amount | Price |

| Automatic roll dispensing equipment | 1 | 8500$ |

| Embossing part | 1 | 24000$ |

| Measuring device with infrared light | 1 | 600$ |

| Leveling device | 1 | 600$ |

| Molding equipment | 1 | 35000$ |

| Mixer and spreader for polyurethane (PU) A and B components | 1 | 24000$ |

| Special platform for aluminum coil | 1 | 4900$ |

| Laminating equipment | 1 | 89000$ |

| PLC control panel | 1 | 7600$ |

| Cutting equipment with servo system | 1 | 9800$ |

| Transportation costs (container 40HQ) | 3 | 33000$ |

| TOTAL | 237 000 USD | |

Based on 0 reviews

Be the first to review “Production line of PU insulating decor products for walls” Cancel reply

Related products

-

Metalworking equipment, Solution product lines

Iron fences (sets) production line

0 out of 5(0)Hello, dear followers and customers of AFEX-GROUP. As we all know, the production sector in our country is developing more and more, and the production mechanisms are also improving. This post is about a set of equipment for the production line of iron fences (sets), which are widely used in agriculture and household, as well as in the construction industry.

SKU: n/a39,700$ -

Metalworking equipment

Metal cylinder containers production line

0 out of 5(0)“AFEX-GROUP” offers a production line of metal containers with hooks from 1 liter to 5 liters with high profit for our entrepreneurs. For our customers who purchase this line, our company will provide close practical support in starting this activity.

SKU: n/a118,000$ -

Construction equipment, Metalworking equipment

Gypsum board profile production equipment (double mold)

Construction equipment, Metalworking equipment

Construction equipment, Metalworking equipmentGypsum board profile production equipment (double mold)

0 out of 5(0)Gypsum plasterboard products have entered the modern construction industry at a rapid pace, and in turn, the demand for accessories necessary for the installation of this product has increased significantly. Due to the increase in demand, metal profiles began to take the place of wooden slats on the market.

SKU: n/a19,500$

There are no reviews yet.