MDF door production line AF-L012

Out of stock

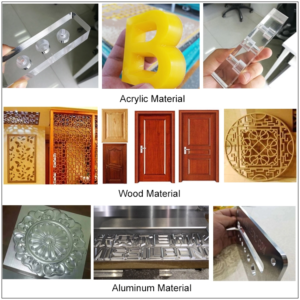

Earlier, we were amazed by the work done by flower craftsmen, now our master craftsmen are turning to modern technologies to make their work easier and to make it better. Modern equipment guarantees that you will do your work with quality, without errors and on time. Controlling this equipment, which seems complicated at first glance, is not a difficult task. Our equipment has a computerized control system, and we will introduce you to the basic skills. Wooden doors are being replaced by aluminum profile and MDF doors every day. In such conditions, you also have the opportunity to make good money by starting this business. MDF panels are sold ready-made, and they are cut to the required size, the customer’s desired pattern is printed on it, the layers are fastened together with the help of a hot press, the product is varnished, and at the last stage, holes are made for installing a lock on it. Although the production process seems simple at first glance, producing a good product requires good design skills and love from you. With the equipment we offer, you can start making simple furniture.

29,400$

Out of stock

First, we start the work by cutting the MDF panel to the required size. It is custom made for us or based on customer’s requirement and the size is different in each province customers. For this we will need a double saw cutting equipment. The double-saw cutting equipment cuts the product in the same plane without blowing the edge, for this, the product comes out with a high-quality product due to the high speed of the small front saw.

| Double saw cutting equipment | |

| Model | AFX-MJ6132YII |

| Volume size | 3200x3150x900mm |

| Table size | 3200x375mm |

| The width of the saw and hedge cutter | 1250 mm |

| Cutting height | 80mm(45 Max 55mm) |

| Diametric of the saw blade | 305mm |

| The speed of the saw blade | 4000/6000 rpm |

| Main blade speed | 8000 rpm |

| Power | 5.5kw |

| Weight | 850/950 kg |

After cutting our MDF panels to the required size for the door, they have to be decorated with various patterns according to the customer’s requirements. If your customer wants glass doors, we can make them too. The main requirement for the craftsman who uses the rover equipment is that he has the skills to use the AutoCAD program.

| Pattern engraving rover equipment | |

| Model | AF-1325CNC |

| Control Panel | A separate panel |

| Work area size | 1300x2500x220mm |

| Motor type | Spindle 3 kw/h |

| Cooling system | Water cooling |

| Driver type | Leadshine 882 |

| Transmission | X, Y, Z |

| Inverter | 3.7kw |

| Size | 3150x2120x1950 |

| Weight | 1000 kg |

| Work program | Type#ARTcam/Ucancam |

The base for the MDF door is made, then the two surfaces of the base are covered with MDF, and the parts that are connected to the base are well glued and strengthened using hot surface hydraulic pressing equipment. No nails or other reinforcing materials are used in this process, so our products are of high quality.

| Hydraulic hot surface press(100T) | |

| Model | HPM 214*6 |

| Press power | 1000KN/100T |

| Number of floors | 1 floor |

| Max temperature | 120C |

| Heating system | Electric heating (with thermal oil) |

| Total power consumption | 28.5 kw/h |

| Voltage | 380v50hz |

| Desktop (Mylar coated) | 2500x1300x42mm |

| Size | 3600x1710x2080mm |

| Weight | 7600 kg |

This auxiliary equipment is necessary to prevent excess waste from entering our production plant and to ensure the smooth operation of our equipment. The operation of the equipment is quite simple, it collects waste in special bags, you can clean it and put it back after the work is done.

| Vacuum cleaner | |

| Model | M9020 |

| Suction power | 3150m3/h |

| Wind speed | 35-40m/second |

| Motor speed | 2900R/min |

| Total power consumption | 3 kw/h |

| Voltage | 380v50hz |

| Bag size | O470x2 |

| Weight | 70 kg |

This equipment that we offer you is very convenient, it can be used even after the door is installed in the apartment. Works both vertically and horizontally. The use is somewhat simplified, and the probability of mistakes in the process of use by masters is high.

| Lock opening device for MDF door | |

| Model | LD2400 |

| Voltage | 220v50hz |

| Max punching speed | 2000mm/min |

| Management | Manual, semi-automatic |

| Total power consumption | 550w/h |

| Weight | 5 kg |

After the work is completed, it is necessary to paint our doors well with paint and varnish. You will need an air compressor for this process. We did not include it in the line because compressors are not difficult to find in the local market.

Prices

Rover equipment $7,400

Hydraulic hot surface press (100T) $16,800

Vacuum cleaner $400

The lock replacement tool is $1,300

Double saw cutting equipment $3,500

The total price is $29,400

There are no reviews yet.