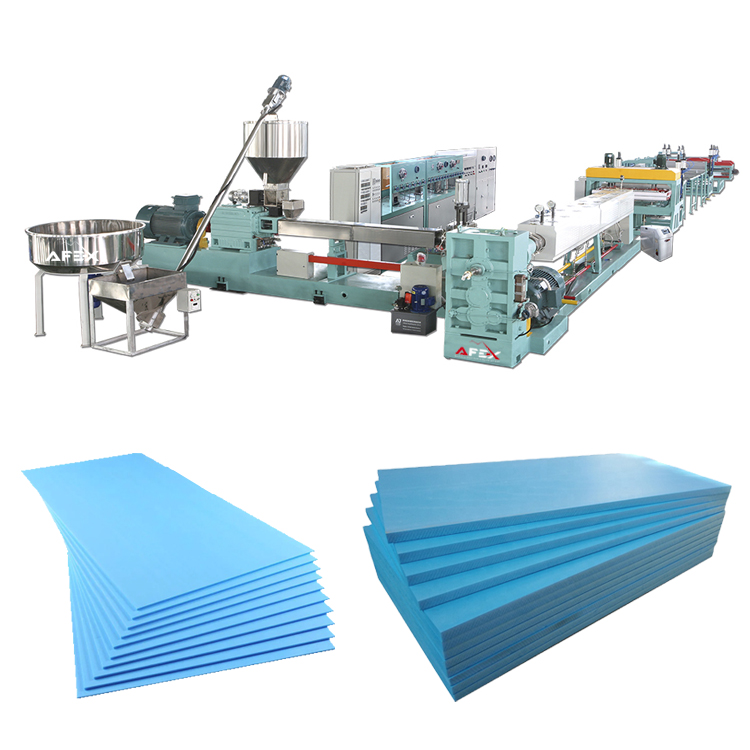

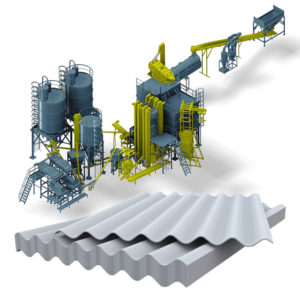

Insulating XPS panels production line

Out of stock

AFEX-GROUP continues to provide new and modern production lines. Using the equipment of the next production line, entrepreneurs can produce xps foam foam. Below you can familiarize yourself with the general information of these devices.

890,000$

Out of stock

About the product

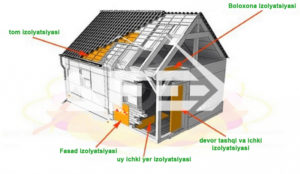

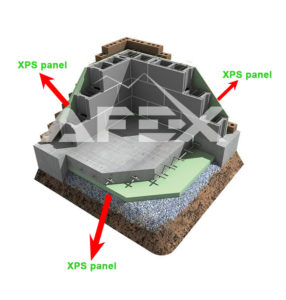

Extruded polystyrene (XPS) is a lightweight and flexible insulating rigid foam that resists water absorption, making it a good choice for a number of construction and commercial applications. XPS panels are used for a variety of purposes – wall and ceiling insulation, room cooling, under concrete slabs (i.e. under parking lots) and even for architectural purposes.

Residential insulation: between walls, for internal parts of balconies and roofs.

Roof Insulation: XPS insulation can be placed on top of the roof or as interior insulation.

Agriculture: XPS panels can be used as roofs, ceilings or interior walls for poultry houses, mushroom farms and factories.

Temperature maintenance: used in cool rooms, cold storage floors and refrigerators.

This product is one of the energy-saving products. Due to the fact that the production process requires less energy than other types of products, it emits less harmful gases to the environment. Due to this, the emissions to the environment can be reduced by up to 25%. It is up to 40 percent more efficient at trapping heat and cold when used for homes and buildings.

XPS panel applications

General information

- Production volume: 400-600 kg/hour

- Density: 26-45 kg/m3

- Finished product width: 600 mm

- Length of finished product: 1200 mm

- Finished product thickness: 20-100 mm

- Product composition: PS, foam chemical, foaming chemical, masterbatch and other substances (according to demand)

- Total power: 200 kw, 380V 50Hz

- Compressed gas consumption: 1.5 m3/min

- Water consumption: 15m3/hour

- Required area size: 70*10m*6m (length*width*height)

Equipment list

- Five-station raw material mixing system

- System of twin-screw extruders

- Raw material measuring part

- Second single-screw extruder (with static mixer)

- Temperature control part

- Calibrator

- Cooling parts

- Milling equipment

- Alignment-transmission equipment

- Cutting equipment

- Control point

Now we can get acquainted with the technical parameters and production stages of all the equipment.

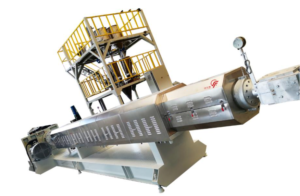

Five-station raw material preparation system

In this part, one of the main equipments – stainless steel was used to make the silo. There are also 2 GPPS vacuum delivery units to deliver raw materials to the mixer.

With the help of 5 stations, 400-1000 kg of raw materials can be melted and ready for production in one hour.

Twin screw extruders

The most basic equipment of the production line is, of course, extruders. With the help of extruders, ready raw materials are melted and the product is released. The line uses a 2-stage, i.e., two-screw extruder.

| Motor | AC motor Siemens |

| Power | 132 sq |

| Screw size | F 75mm |

| Barrel material | 38CrMoAIA |

| Cooling method | Through water |

Raw material measurement system

This production unit consists of several pieces of equipment. The most basic equipment is pumps, which measure and deliver the required amount of raw materials to you. Pumps are made of 38CrMoAIA metal with high hardness and will serve for many years.

CO2 pumps

| Power | 7,5 kw |

| Capacity | 15-75 L/h |

Butanol pumps

| Motor | 5,5kw |

| Pressure | 50mpa |

| Capacity | 72 L/h |

Ethanol pumps

| Motor | 2,2kw |

| Pressure | 50mpa |

| Capacity | 32 L/h |

Single screw extruder

| Type Single screw extruder | Single screw extruder |

| Screw diameter | F200 mm |

| Screw material | 38CrMoAIA |

| Motor | 90kw AC motor |

| Static mixer | DG200 |

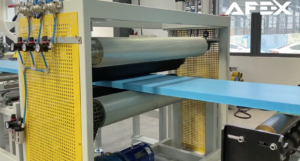

Calibrator

| Total power | 11 sq |

| Dimensions | 1000*1500 mm (length*width) |

| Heating | Aluminum contours |

| Lifting weight | 5 tons |

| Speed | 19 m/min |

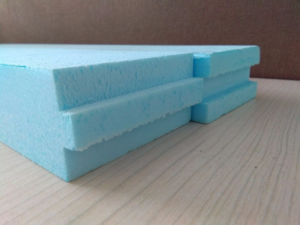

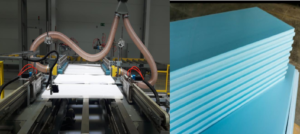

Corner cutting equipment

| Type | Electric saw |

| Engine power | 7,5kw |

| Cutting dimensions | 600-1200mm |

Corner processing equipment

| Working width | 550-650mm |

| Working thickness | 20-120mm |

Surface treatment equipment

| Model | FN-600 |

| Working width | 550-650mm |

| Working thickness | 20-120mm |

| Total power | 12kw |

| Blade size | Ф 160*1260 mm |

| Accuracy level | 0,2mm |

Basic cutting equipment

| Working thickness | 20-100 mm |

| Working width | 600-1200 mm |

| Working length | Longer than 1180 mm |

| Accuracy level | 1-2 mm |

| Motor | 4kw servo motor |

Horizontal processing equipment

| Working width | 600mm |

| Working thickness | 20-120mm |

| Slot width | 15mm |

Electronic control point

Based on 0 reviews

Show reviews in all languages (1)

There are no reviews yet.