Foam block (foam block) production line AF-L014

Available on backorder

With the development of the construction industry, a large part of the market of wall materials has been filled with lightweight concrete blocks. Today there are many types of them, but the most popular of them are foam blocks and gas blocks. Both are very popular with consumers. Using this opportunity, the company “AFEX-GROUP” recommends to you the production line of foam blocks. Let’s see what advantages the foam block has compared to other types of building bricks.

15,600$

Available on backorder

Production technology of foam concrete blocks

To understand the physical properties of materials, it is necessary to know the technology of their production. All blocks of foam concrete are obtained by creating air bubbles in the concrete solution. The method of foaming and the composition of the mixture depends on the properties of the obtained blocks. The foam block we are interested in is produced based on this technology:

The composition of the foam block includes sand, cement, water, and plasticizers (the price of a special component with a penoobrazavatel-mixed foam is 14,000-20,000 soums/kg). Product manufacturing technology has several stages. With the help of special equipment, the mixture is prepared in accordance with the table below, it is poured into a special mold and after drying it is removed from the mold. Currently, ready-made foam blocks are sold in our country for 430-480 thousand soums per 1m3.

RECOMMENDED QUANTITY OF ELEMENTS IN THE INGREDIENT

| Bulk density kg/m3 | 400 | 600 | 800 | 1000 | 1200 | 1400 |

| Sand(kg) | – | 210 | 420 | 590 | 780 | 950 |

| Cement(kg) | 300 | 310 | 320 | 350 | 360 | 380 |

| Water for mixing(L) | 110 | 110 | 120 | 120 | 140 | 150 |

| Water for foam (L) | 60 | 54 | 46 | 42 | 35 | 28 |

| Penoconcentrate (Peneobrazavatel) kg | 1,5 | 1,3 | 1,2 | 1,0 | 0,9 | 0,7 |

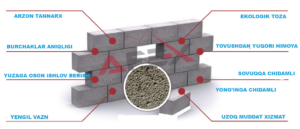

Advantages of foam blocks

Accurate measurements. You can easily build walls without adjusting each element to specific parameters.

That you don’t need to be experienced to use Lego-shaped foam blocks;

Does not release heat. This helps to save energy for heating later;

Does not absorb moisture. Therefore, the building of such material does not require additional water protection;

Inside the house, unlike cinder block buildings, outside noise is not heard. For those who like to live in silence, the house of the foam block is perfect;

The lightness of each block. It is very durable and does not require an expensive foundation, there is no need to use special equipment to install the walls.

Foam concrete allows easy installation of cables and other communications.

Environmentally friendly product. Different safety for human health.

Another difference between foam blocks and cinder blocks is that, if we talk about the properties, the first ones are similar to ordinary bricks. But it is very cheap. Shipping will also be cheap. You can quickly build a house from such materials. The products are fully suitable for the construction of small private houses, houses or low-rise buildings.

If you liked this product, now we will introduce you to the manufacturing technology of this product in detail.

View of the equipment from different sides

Technical specifications:

| Foam generator equipment | |

| Produced | China |

| Model | FBM-12 |

| Production capacity | 12m3/hour |

| Vertical transfer height of mixture (MAX) | 30 m |

| Horizontal Transmission Length(MAX) | 80 m |

| Pressure force(MAX) | 1.6Mpa |

| Output pressure force | 1.2Mpa |

| Power consumption | 7.5kw/h |

| Voltage | 380v50hz |

| Size | 1600*1200*1300 mm |

| Weight | 900 kg |

|

|||||||||||||||||

| Screw conveyor | |

| Produced | China |

| Model | SC-3M |

| Material | Metal steel |

| Power consumption | 1,5 kw/h |

| Voltage | 380v 50hz |

| Screw length | 3 m |

| Weight | 90kg |

Based on 0 reviews

Show reviews in all languages (1)

There are no reviews yet.