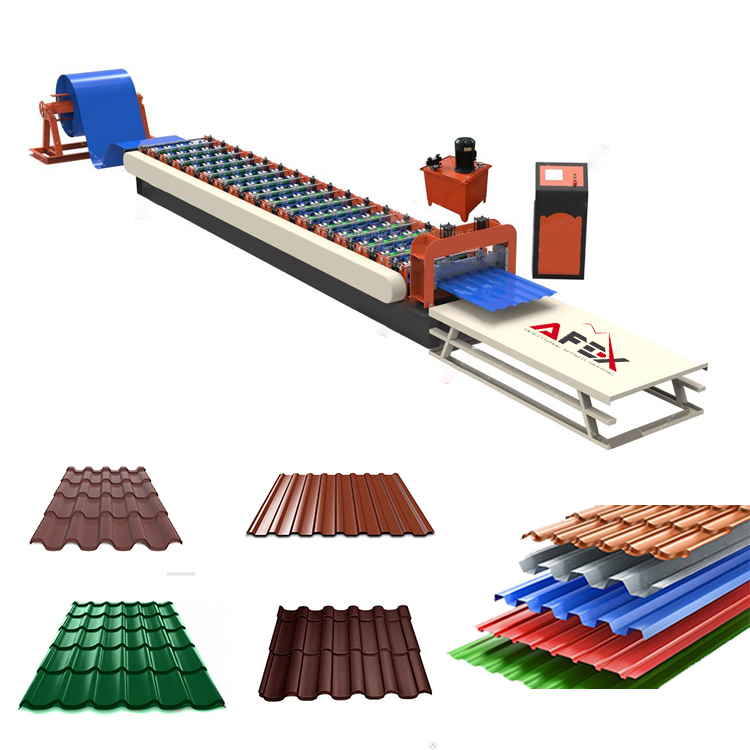

Equipment for the production of metal tiles (profnastil).

Profnastil products are an integral part of construction. Almost all local constructions have demand for profnastil products, taking this into account, the company “AFEX-GROUP” offers you profnastil production equipment below.

14,700$

General information

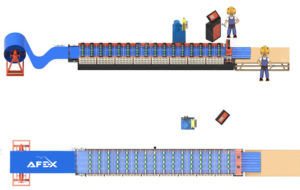

Production area: 16 meters*6 meters, not less than 96m2

Production speed: 10-15 meters/minute

Workers: 2 people

Voltage: 380 V

Power consumption: 12 kW

The production process of metal tile (profnastil) consists of three stages:

- A roll is placed on the main equipment

- It goes to the main forming equipment and gets the desired profile shape

- The hydraulic shears are inserted into the equipment and cut to the required size using this equipment

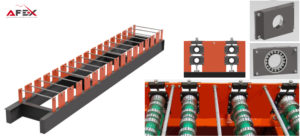

Hardware appearance:

| Basic equipment | |

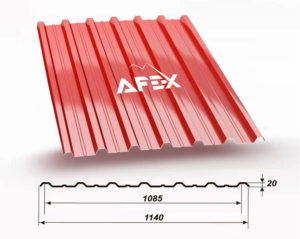

| Product thickness | 0.2-0.7 mm |

| Product width | 1250 mm |

| Solid shaft materials | High quality 45 grade steel |

| Shaft diameter | 80mm |

| Number of roller molds | 14 |

| Roller material | Cr12mov |

| Speed of operation | 10-15m/min |

| Transmission method | Chained |

| Power | 8kw motor |

| Raw material | Metal roll sheets |

| Equipment size (length*width) | 7.8m*1.7m |

| Weight | 3.5 tons |

| Type | PLC controlled hydraulic cutting |

| The material of the cutting blade | Cr12 |

| Hardness level | 50-65 HRC |

| Cutting accuracy | ±1mm |

Equipment operation diagram:

Components of the equipment:

A. Delivery Platform

B. Basic formation

C. Hydraulic system

D. Equipment base

E. Management system

F. Hydraulic cutting

G. Schedule

H. Khomashyo

A. Delivery Platform

Features: separated same material, two wheel adjustment function.

Function: solid raw material, the possibility of adjusting the width of the raw material.

Advantages: stable production, left and right sides are balanced.

B. Roll forming equipment

C. Hydraulic control

D. Electronic control

| Control equipment | |

| Type | PLC control |

| PLC brand | Delta |

| Frequency converter | Delta |

| Touch screen | 10 inches |

E. Protection module

F. Hydraulic cutting

Cutting thickness: 0.1mm-2mm

Based on 0 reviews

Show reviews in all languages (1)

Be the first to review “Equipment for the production of metal tiles (profnastil).” Cancel reply

Related products

-

Metalworking equipment, Solution product lines

Iron fences (sets) production line

0 out of 5(0)Hello, dear followers and customers of AFEX-GROUP. As we all know, the production sector in our country is developing more and more, and the production mechanisms are also improving. This post is about a set of equipment for the production line of iron fences (sets), which are widely used in agriculture and household, as well as in the construction industry.

SKU: n/a39,700$ -

Metalworking equipment

Metal sheet CNC cutting (guillotine) equipment (6*3200)

0 out of 5(0)Key Features: Fully European design, streamlined appearance, monoblock, welded steel frame, ST44 A1 material, high tension equipment. Since the cutting beam is designed in an internal inclined structure, the slabs fall very easily and the accuracy of the products is also guaranteed.

SKU: n/a15,200$ -

Construction equipment, Metalworking equipment

Gypsum board profile production equipment (double mold)

Construction equipment, Metalworking equipment

Construction equipment, Metalworking equipmentGypsum board profile production equipment (double mold)

0 out of 5(0)Gypsum plasterboard products have entered the modern construction industry at a rapid pace, and in turn, the demand for accessories necessary for the installation of this product has increased significantly. Due to the increase in demand, metal profiles began to take the place of wooden slats on the market.

SKU: n/a19,500$ -

Metalworking equipment, Solution product lines

Fully automatic aluminum foil container packaging equipment

Metalworking equipment, Solution product lines

Metalworking equipment, Solution product linesFully automatic aluminum foil container packaging equipment

0 out of 5(0)The equipment is 20-999mm long, and can realize the features of automatic lubrication, automatic self-maintenance and automatic self-control of all parts of the set with a fully automatic operation system.

SKU: n/a49,000$

There are no reviews yet.