Fully automatic aluminum foil container packaging equipment

Out of stock

The equipment is 20-999mm long, and can realize the features of automatic lubrication, automatic self-maintenance and automatic self-control of all parts of the set with a fully automatic operation system.

49,000$

Out of stock

Nowadays, the demand for disposable containers is increasing day by day in our country. Along with plastic containers, the demand for aluminum foil containers is also increasing. In addition to being convenient to use, aluminum foil containers are popular because they can be reheated and do not emit toxins. By starting this business, you can work in cooperation with food delivery points, and depending on their demand, you can also make the top cover from aluminum foil or paper cardboard. In foreign countries, hot food is not placed in PS, PP and PE containers, aluminum containers are used instead. Over time, this norm will also expand in us. Our company AFEX-Group will continue to offer you equipment for the production of demanding products that are expected to increase in demand in the future. Let’s get acquainted with our today’s line:

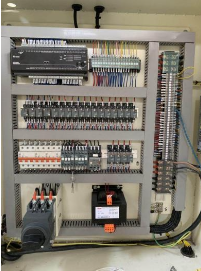

The fully automatic production line includes: decoiler and lubricator + servo drive unit + high precision forming machine + automatic stacker + waste metal collector.

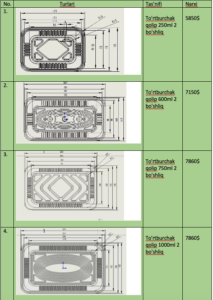

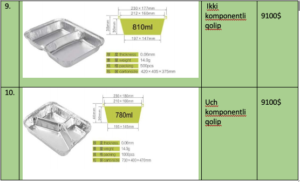

Mold types:

Lubrication with a separate type of decloir and equipment NC taminot system

NC machine control system parameters

| Part names | Parameters |

| The maximum diameter of the package | 1000mm |

| The inner minimum diameter of the package | 80mm |

| The maximum width of the package | 750mm |

| Maximum package weight | 500kg |

| Taminot part working speed | 10-30m/min |

| The length of the taminot part of the equipment | 20-9999mm |

| Taminot part performance accuracy | +/-0.2mm |

| Motor power | 2KW |

| Voltage | 380/220V |

| Equipment weight | 800kg |

| External dimensions | 1200*1400*1100mm |

The equipment is 20-999mm long, with a fully automatic operation system, all parts of the set can realize automatic lubrication, automatic raw material supply part, automatic optical inspection features, which is accurate positioning and automatic adjustment range. provides The device has the precision of self-control and even oil coverage. This equipment works with high precision and low waste, which allows you to get the most out of your raw materials. Our equipment is easy to install, has a simple control system and low noise. It is an ideal automatic machine for aluminum foil and is a great machine for paper and other metal rolls. It also guarantees the success of your project.

Hardware parts:

| Model (45ton) | Classification |

| Nominal pressure | 450kn |

| Slider stroke power | 220mm |

| Slider shot in one minute | 30-70 times |

| The maximum height of the mold set | 450mm |

| The slider adjustment part | 60mm |

| Sizes of the slider bottom | 340*410mm |

| Sizes of a toothed punch | 50*60mm |

| Amplifier dimensions | 800*900mm |

| Total power consumption | 5.5 kw |

| Weight | 5000kg |

| External dimensions | 1600*1100*3200 |

Auto stacker (equipment for stacking manufactured products) (optional)

| Part names | Parameters |

| Conveyor width | 550mm |

| Conveyor belt height | 92025mm (height can be adjusted as desired) |

| Minimum dimensions of the container | 100*100mm (sizes can be customized later) |

| Maximum dimensions of the container | 500*300mm

215*300mm |

| Maximum mounting height | 420mm (it mainly depends on the dimensions of the container) |

| Needs air | 0.2m kub min |

| Hardware power consumption | 3 kw |

| Weight | 1000kg |

| External dimensions | 2800*780*1500mm |

Waste collector system (optional)

Function: As part of the production line, the collector plays an important role in this. Its main function is to collect excess aluminum foil. The vacuum adsorber collection system collects the waste in a box and then compresses the aluminum scrap into balls.

Product Features: It uses a vacuum adsorb collection system, which is easier to collect the foil. Low noise. To reduce noise pollution, knife and flat cutter are used to cut materials.

Screw compressor (optional)

| Part names | Parameters |

| Gas volume | 3.6 m3 per minute |

| Pressure release rate | 0.8 MPa |

| Maximum release pressure | 0.8 MPa |

| Power consumption | 22 KW |

| Input power ratio | 8.1 KW (m3/min) |

| Nominal speed | 2949 r/minute |

Container stamp mold (optional)

Mold life: 10000000 times.

Please note: the price of the mold depends on the size of the container. Special prices will be calculated according to your sample or drawing. Thank you for your attention!

Based on 0 reviews

Be the first to review “Fully automatic aluminum foil container packaging equipment” Cancel reply

Related products

-

Metalworking equipment

Metal cylinder containers production line

0 out of 5(0)“AFEX-GROUP” offers a production line of metal containers with hooks from 1 liter to 5 liters with high profit for our entrepreneurs. For our customers who purchase this line, our company will provide close practical support in starting this activity.

SKU: n/a118,000$ -

Metalworking equipment

AF-M8 Marking equipment for metal pipes

0 out of 5(0)Metal pipe embossing equipment is used for making beautiful embossing on any metal pipe. The equipment has simple operation, high production efficiency, stable forming effect and other features.

Pipe materials: stainless steel/copper/carbon steel/iron/galvanized/aluminum etc.

Pipe shape: Round and other shapes.

Application: Pipes designed for furniture, construction and other industries.

SKU: n/a28,000$

There are no reviews yet.