Cotton and sunflower oil production line (from raw material 8-10T/day)

1 in stock

Decree of the President No. PF-6094 dated 10.27.2020 was announced in order to raise oil production to a new level of quality in our country and to control the producers’ organization of work in a full cycle. The main change in it is as follows:

109,000$

1 in stock

“technical cotton seed – regardless of its organizational and legal form, it is relevant for finished products processed in the full technological cycle of technical cotton seed (gin crushing, hydrothermal treatment, pressing, extraction, refining, deodorization and packaging workshops) to local enterprises with hygienic summary and certificates of conformity. In this case, in order to obtain a hygienic conclusion and certificates of conformity for the production of ready-made cotton oil, technical cotton seed is sold to local enterprises, regardless of the form of ownership, on the basis of a certificate of commissioning of the district or city mayor, in the amount of up to 5 tons, and the resale of purchased technical cotton seed is only through stock exchanges. is done. The control over the purposeful processing of the technical cotton seed in the full technological cycle of the enterprises and whether they have hygienic conclusions and certificates of conformity confirming the quality of the products is carried out by the inspection of control over the Agro-industry complex under the Cabinet of Ministers in accordance with the procedure established by law.

As a result, many applications are coming to our company. With the interests of you entrepreneurs in mind, we recommend a full-cycle compact line made in Chinese factories on a special order basis with our team.

PRODUCT DELIVERY ELEVATOR (4 units)

The main task of elevators is to deliver products from one stage to another. The height of the elevator can be adjusted according to the height of your building. 4 elevators are required for the line we offer you. According to the customer’s request, the elevator can be replaced with a screw elevator.

EQUIPMENT FOR DISC SEEDING

In order to obtain oil from the seed, it is necessary to grind it first. For biting, a disk biting equipment is used. The crushed product is sent to the next step, i.e., a circular sieve, to separate the husk (shulkha) and the kernel.

| Disc harrowing equipment | |

| Manufacturer | China |

| Model | DCM500 |

| Energy type | Electric |

| Voltage | 380V |

| Electricity consumption | 7.5kw/h |

| Weight | 110 kg |

| Raw material | The seed |

| Size | 1300*600*1200mm |

| Material | CR38 metal |

| Operating speed per day | 450-500kg/hour of seed |

2-STAGE SEPARATOR FOR SEPARATING SEED HULLS AND PILES

The seed that comes out of the threshing machine goes through a special 2-stage sieving process to separate it from the kernel. This equipment can separate 93-97% of seed kernels. It depends on the degree of hairiness of the seed you use. The equipment has 2 outlets, one of which is the seed coat, and the other is where the seed kernel comes out. The seed kernel goes to the next stage.

| 2-stage separator that separates the husk (shulkha) and the core of the seed | |

| Manufacturer | China |

| Model | AFX Separator 500mm |

| Energy type | Electric |

| Voltage | 380 V 50hz |

| Electricity consumption | 11kw/h |

| Weight | 940 kg |

| Material | Carbon metal |

| Working power | 800-1000 kg per hour |

| Size | 1200*900*1600mm |

SEED BURNING EQUIPMENT

A seed thresher crushes the seed. This makes it easier to release the oil from the seed. The seed kernel passes between two smooth shafts and is spread. You have the option to compress to the size you need.

| Equipment for crushing seed kernels | |

| Manufacturer | China |

| Model | AFX FLAKER 500mm |

| Energy type | Electric |

| Voltage | 380 V 50hz |

| Electricity consumption | 11kw/h |

| Weight | 940 kg |

| Material | Carbon metal |

| Working power | 800-1000kg hour |

| Size | 1200*900*1600mm |

HYDROTHERMAL PROCESSING EQUIPMENT FOR SEED CORE (3 Compartments)

| Equipment for hydrothermal treatment of seed kernels (3 sections) | |

| Manufacturer | China |

| Model | AFX COOKER 3 P |

| Energy type | Electric |

| Voltage | 380V50hz |

| Electricity consumption | 3 kw/h |

| Weight | 1140 kg |

| Par pressure | 10BAR(1Mpa 100 kg/hour_ |

| Size | 1200*1200*2400mm |

| Material | Carbon metal |

| Heating method | Using Par |

SPECIAL PRESS FOR OIL EXTRACTION (AX-130M)

Press equipment is used to squeeze oil from your product. The average amount of residual fat in the feed is 5-5.5%. For example, the percentage of oil extraction from seeds is up to 16%. The equipment set is equipped with a special 22kw motor produced at the factory.

| Special screw press for extracting oil (M130) | |

| Manufacturer | China |

| Model | 6YL-130 |

| Energy type | Electric |

| Voltage | 380V |

| Electricity consumption | 18.5 Kw/h |

| Weight | 580 kg |

| Raw material | Seed, sunflower pistachio, sesame, safflower and other leguminous products |

| Operating temperature range | 20C-150C |

| Size | 1710*700*1650 |

| Material | CR38 metal |

| Electric motor | 18.5 kw 1500 rpm will be charged separately by the buyer |

| Operating speed per day | 8 T seed |

EXTRACTION EQUIPMENT

Oil and oil come out of the oil pressing equipment. Extraction equipment is used to extract the 5-6% oil remaining in the pot. The extraction process is carried out using Hexane or Ethanol 95%. The oil is extracted from the micelles by heating and vacuum. 0.5-1% of fat remains in the resulting meal. Since the extraction process is carried out using ethyl alcohol, the oil obtained from it can be consumed by refining and deodorizing. Ethyl alcohol evaporates quickly and completely from the oil. The equipment is fully equipped with anti-explosion shields and motors. Work to be done by the buyer for the extraction equipment:

- Solvent (Hexane or Ethanol above 95%) storage tank and assembly pipes

- Water for cooling and cooling tower or chiller for condensing

- Water pump

- Special space on demand for concrete construction and individual works

| Extraction and concentration equipment | |

| Manufacturer | China |

| Model | AX-3000 |

| Energy type | Electric |

| Voltage | 380V50hz |

| Electricity consumption | 5.5 kw/h |

| Weight | 140 kg |

| Par pressure | 10 Bar (1 Mpa 200kg/h) |

| Size | 5000*700*2400mm |

| Material | SUS304 stainless steel |

| Solvent | Ethanol 95%, Hexane, Extraction gasoline |

PLATE FRAME FILTER FOR OIL (model 350)

| Oil filtering equipment | |

| Manufacturer | China |

| Model | TD-26 |

| Energy type | Electric |

| Voltage | 380V |

| Electricity consumption | 1.5kw/h |

| Weight | 160 kg |

| Raw material | For cottonseed oil, sunflower oil, sesame oil, safflower and other leguminous oils. |

| Operating temperature range | 20C-70C |

| Size | 1200*800*1050 |

| Material | CR38 metal |

| Electric motor | 1.5kw 1500rpm is added |

| Speed of operation | 300-350L/hour |

SPECIAL PUMP (3 pieces)

Special pumps are used to transport the oil after it leaves the filter to the next stage and then to packaging. These pumps operate at 380v 50hz and have a power consumption of 3kw/h.

OIL REFINING, NEUTRALIZER, BLEACHING AND DEODORATING EQUIPMENT GL-2000

Refining and deodorizing processes are one of the main processes that determine the quality of this oil. below we will briefly explain to you what parts the equipment is made of and its function

- Refining tank – for oil degumming using hot water

- Deoxidation Neutralizer tank- For neutralization using alkali

- Bleaching tank – sand cleaning and bleaching

- Filter- retains sediment products in the oil

- Deodorizing Tanker- Eliminates unpleasant odors in oil

- Steam generator – to heat the tank for the deodorization process

- Filter – for final filtration before consumption

- Catcher – to catch harmful substances

- Tanker for hot water and alkali

- Tanker for bleaching raw materials and residual product

- To transfer from the pump-filter to the bleaching tank

- Vacuum pump- To create a vacuum condition in the tanker

- Control Panel

- Stairs and platform for easy control

| Oil refining, neutralizing, bleaching and deodorizing equipment GL-2000 | |

| Manufacturer | China |

| Model | GL-2000 |

| Energy type | Electric |

| Voltage | 380V |

| Electricity consumption | 54kw/h (with steam generator) |

| Weight | 1180 kg |

| Raw material | Seed, sunflower, sesame or soybean oil |

| Size | 6000*1500*2400 mm |

| Material | SUS304 stainless steel |

| Operating speed per day | It can process oil up to 2000L |

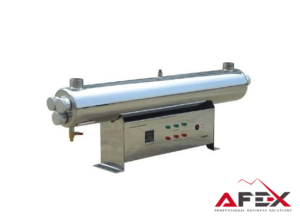

Oil UF sterilization equipment

It is desirable to sterilize the oil before packaging. Prior to packaging in a chilled state, the sterilized part is directed to the packaging equipment.

| Oil UF sterilization equipment | |

| Produced | China |

| Voltage | 220v 50hz |

| Power consumption | 500w/h |

| Material | 304 SS stainless metal |

| Weight | 30 kg |

| Production volume | 500L/hour |

| Operating temperature | 5-60C |

MINI LABORATORY EQUIPMENT FOR OIL

It is required to undergo quality control before packing the product every day. In this case, the probability of our entrepreneurs producing high-quality products is high.

EQUIPMENT FOR MANUFACTURING PET CONTAINERS FOR OIL PACKAGING

PET bottles remain the main packaging product for cottonseed oil and sunflower oil. To produce PET bottles, you need a PET capsule, which can be found in different regions of our country.

| Equipment for the production of pet dishes | |

| Produced | China |

| Voltage | 380v50hz |

| Power consumption | 14kw/h |

| Material | Carbon metal |

| Weight | 1100 kg |

| Pet container size | Max 2L MIN 0.33L |

| Speed of operation | 800-1000 units/hour |

| Size | 1630*620*1590mm/750kg |

| Capsule heating equipment | 1780*570*1380mm/350kg |

| Additional parts | Air compressor, 1 mold, air filter |

SPECIAL HIGH PRESSURE COMPRESSOR

| High pressure special compressor | |

| Manufacturer | China |

| Model | CWM-1,2/30YQH |

| Energy type | Electric |

| Voltage | 380V50hz |

| Electricity consumption | 15 Kw/h |

| Weight | 640 kg |

| Air pressure | 30Bar(3Mpa) |

| Size | 2000*1100*1600mm |

| Material | Carbon metal |

| Air supply flow | 1.2 m3/min |

OIL TANK FILLING AND COVERING EQUIPMENT

When the baklashki are ready, they are filled with oil, the lid is closed and they are made into a finished product. The equipment can pour into bottles from 1l to 5l

| Equipment for filling and capping oil containers | |

| Produced | China |

| Voltage | 220v 50hz |

| Power consumption | 500w/h |

| Material | SS304 stainless steel |

| Weight | 280 kg |

| Pour size | 1L-5L |

| Speed of operation | 100-300 pieces/hour |

| Size | 600*598*1300mm |

| Capsule heating equipment | 1780*570*1380mm |

| Additional parts | Air compressor |

PARAGENERATOR (STEAM BOILER)

The steam boiler mainly supplies steam for the extraction equipment and the hydrothermal treatment equipment for the kernel.

| Paragenerator (steam boiler) | |

| Manufacturer | China |

| Model | JYV- |

| Energy type | Electric |

| Voltage | 380V50hz |

| Electricity consumption | 36kw/h |

| Weight | 140 kg |

| Par pressure | 10BAR(1Mpa) |

| Size | 1000*700*1400mm |

| Material | Carbon metal |

Based on 0 reviews

Show reviews in all languages (1)

There are no reviews yet.