Automatic metal tape production line

Out of stock

Along with all the countries of the world, the metallurgical industry continues to grow steadily in our country. Of course, all these are processes related to the number of residents and consumers. Some products, which have the possibility of production in our country, but continue to be imported, are surprising. We will introduce information and technologies related to the production of one such product, that is, metal tapes.

198,000$

Out of stock

Cut-to-size metal strips are widely used in the automotive, home appliance, packaging, building materials and metal processing industries.

In our country, metal tapes are one of the products that are widely used in the industry, mainly in components, clips, plasterboard profiles, pipes, profiles and other fields.

You can meet the demand for the product not only in the market of our country, but also export it to neighboring countries.

You can get more detailed information about this equipment from AFEX GROUP. We will provide you with guaranteed equipment delivery, installation and quality production of your products with the help of qualified technologists!

Required raw materials:

Metal rolls up to 1600mm wide and 0.5-3mm thick.

The thickness of the metal is different, for example, for the production of a plasterboard profile, a metal tape with a low degree of hardness and thickness is used. It is advisable to use a metal tape with a high degree of hardness and thickness for the pipe and profile. The higher the level of hardness during metalworking in equipment, the higher the probability of breakage.

Required field:

All the equipment of the production line can be placed in an area of 225 (25×9) square meters. In addition, there should be storage of raw materials and entrance and exit lanes for trucks. The ceiling height of the building should be at least 6 meters. a lifting device (TAL) is required at the top.

Required Supplies:

Elements of the infrastructure of the industrial facility must be provided with electricity.

• Line power – 150 KW/380V, 50HZ.

•Required transformer-above 200KW/380V, 50HZ.

Line tracking equipment:

• Roll loading device

• Unrolling equipment

• Leveling equipment

• Side deflection device

• Equipment for cutting into strips

• Redundant tape winding (double sided) device

• Looper device

• Separator and traction equipment

• Wrapping equipment

• Unloader for wrapping equipment

• Hydraulic system

• Pneumatic system

• Electronic control system

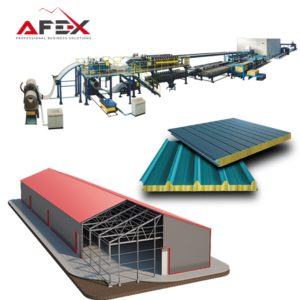

You can see the production lines in the picture below.

We will explain the working mechanism of the automatic metal tape production line with the help of pictures of the equipment.

Metal roll unwinding equipment

We load metal rolls into this equipment with the help of a roll loading device. A roll with an inner diameter of F508 is used for the equipment, and if the inner diameter is large, it is placed through a rubber gasket. Hydraulic cylinder expansion range: F460 – F510mm, stop system with pneumatic pressure, maximum roll width 1600mm.

Leveling

Before cutting to size, it is necessary to level the metal roll through the shafts.

Precision cutting equipment

The diameter of the cutting discs is Х180. The discs can be installed with a width of 1600 mm. Cutting speed ≤80m/min. When cutting 0.3-1.0 mm, 25 rows are formed, when 1.0-1.9 mm are cut, 15 rows, when 2-3 mm are cut, 8 rows are formed.

Redundant tape winding device

In the process of cutting, the equipment, in addition to the metal tapes cut to the required sizes, wraps the excess tapes from the edges of the roll, so that it does not affect the activity of the equipment.

Tape tensioner

This equipment separates and stretches the tapes, a process that facilitates the cutting of the tapes in the cutting equipment. This equipment (Looper) needs a space of 3 meters deep, 2 meters wide and 3 meters long.

Wrap the tape

The ready-made metal tapes that have passed through the looper are ring-shaped and are wound evenly.

Electric wardrobe

There is an electrical control cabinet and two manipulation panels, the equipment is controlled by the PLC system.

Hydraulic system

Pressure: 16Mp

Power: 7.5KW-4 pcs

Oil tank volume: 450L

| Technical indicator | |

| Cutting thickness | 0.5-3mm |

| Cutting width | 300-1600mm |

| Cutting size | 0.3-1.0 mm 25 tapes |

| Cutting size | 1-1.9mm 15 tapes |

| Cutting size | 2-3 mm 8 tapes |

| Cutting speed | Max 80m/min |

| Power source | 380V,50Hz,3 phase |

| Total installation capacity | 150 kW |

| Maximum roll weight | 15,000 kg |

Video from the production process

Based on 0 reviews

Be the first to review “Automatic metal tape production line” Cancel reply

Related products

-

Metalworking equipment

AF-N6 Metal tube winding trace equipment

0 out of 5(0)The advantages of the metal pipe wrapping machine are: simple operation, high production efficiency, stable forming effect, high speed and other features.

Pipe materials: stainless steel/copper/carbon steel/iron/galvanized/aluminum etc.

Application: Pipes designed for furniture, construction and other industries.

SKU: n/a11,000$ -

Construction equipment, Metalworking equipment

Gypsum board profile production equipment (double mold)

Construction equipment, Metalworking equipment

Construction equipment, Metalworking equipmentGypsum board profile production equipment (double mold)

0 out of 5(0)Gypsum plasterboard products have entered the modern construction industry at a rapid pace, and in turn, the demand for accessories necessary for the installation of this product has increased significantly. Due to the increase in demand, metal profiles began to take the place of wooden slats on the market.

SKU: n/a14,800$ -

Metalworking equipment

Metal cylinder containers production line

0 out of 5(0)“AFEX-GROUP” offers a production line of metal containers with hooks from 1 liter to 5 liters with high profit for our entrepreneurs. For our customers who purchase this line, our company will provide close practical support in starting this activity.

SKU: n/a118,000$

There are no reviews yet.