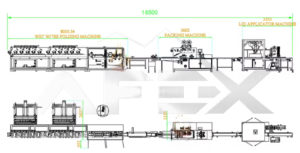

Automatic 12-Row Moist Napkin Production Line (30-120 Pieces)

Currently, one of the most widely used products that has become fully consumed is moist napkins. This type of napkin has become an integral part of our daily lives due to its hygienic advantages and versatility. Considering this, the team at “AFEX-GROUP” LLC presents to you an automatic machine for producing moist napkins.

159,800$

General Information About the Line

Production Area: 300 square meters

Production Capacity: 1800-2400 packs/hour (120-piece napkin)

Energy Type: Electric

Voltage: 380V

Workers: 2-3 people

Water Supply: Necessary

Preparation Vessel for Moistening and Fragrance: 2 units

The process starts with preparing a special fragrant liquid, which is an integral part of the moist napkin production process. A large part of the liquid consists of filtered water and fragrance agents based on a special formula. The volume of the preparation vessel matches your daily production capacity. Excess liquid left in the vessel is returned using a special pump.

| Мanufacturer | China |

| City | Dongguan |

| Voltage | 380V50hz |

| Power Consumption | 4,5kw/hour |

| Product Mixing Section | Available |

| Special Stainless Steel Pump | Available |

| Vessel Material | Stainless Steel SS304 |

| Equipment Capacity | 400L |

| Product Weight | 230kg |

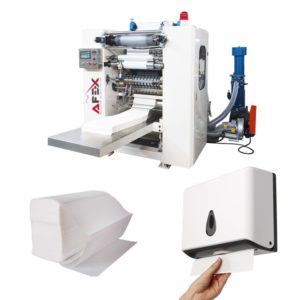

12-Row Moist Napkin Forming and Wetting Equipment

High-performance 12-row raw material supply and forming equipment. The equipment provides moist napkins in the most popular style, namely the N CROSS style, and delivers them to the packing machine in the required volume. With this equipment, it is possible to produce moist napkin products ranging from 30 to 120 pieces. The equipment has a production capacity of 4800 napkins per minute.

| Manufacturer | China |

| Raw Material Reception Width | 900-1200mm |

| Raw Material Thickness | 38-80g/m2 |

| Raw Material Reception Diameter | 1200mm |

| Raw Material Reception Type | Double roll raw material reception, 12-row cutting delivery line |

| Production Speed | 40-65 packs/min (4800 pieces/min when operating in 12 rows) |

| Moist Napkin Size When Folded | Length 100-120mm, Width 80-100mm |

| Moist Napkin Size When Opened | Length 100-210mm, Width 160-220mm |

| Folding Style of Moist Napkin | N cross |

| Control System | Full servo control system (6 axes) |

| Voltage | 380V 50-60HZ |

| Power Consumption | 12KV |

| Equipment Weight | 4000kg |

| Equipment Dimensions | 8560*2530*2050mm (LWH) |

Moist Napkin Gusset Packing Equipment

The packing equipment is created with high engineering skills, where the product is placed inside the packing material, first opening holes to take out the napkin from the packaging, and a special adhesive film is applied over the hole location, thus continuing the packing process. This equipment can prepare products of various sizes. Our equipment packages the finished product design beautifully using the Brick Type Gusset method. The advantage of this type of packaging is that the product side also has a rectangular appearance. The difference is explained in the picture below.

| Manufacturer | China |

| Operating Speed | Maximum 65 packs/min |

| Packing Material | PP,OPP,PET,PE |

| Maximum Packing Material Width | 420mm / Maximum Diameter: 350mm |

| Finished Packing Size | Length 140-300mm * Width 80-110mm * Height 20-80mm |

| Control System | Full servo control system (7 axes) |

| Voltage | 220V 50-60HZ |

| Power Consumption | 4KV |

| Dimensions | 3700*1150*2160mm (LWH) |

Automatic Plastic Cap Sealing and Labeling Machine

This equipment is fully automatic and equipped with HIKVISION brand sensors and cameras for high accuracy. It applies labels to plastic caps and then seals them onto packed moist napkins. The machine can attach caps to 70 packages per minute.

| Manufacturer | China |

| Operating Speed | 50-70 packs/min |

| Cap Delivery System | 2 automatic cap delivery systems |

| Cap Size | Length 20-150mm, Width 20-100mm, Height 5-10mm |

| Label Size | Length 50-100mm, Width 40-80mm |

| Moist Napkin Package Size | Length 50-300mm, Width 60-160mm, Height 20-100mm |

| Control System | Full servo control system |

| Voltage | 200V 50-60HZ |

| Power Consumption | 13KV |

| Equipment Weight | 2000kg |

| Equipment Dimensions | 4400*1650*2400mm (LWH) |

Samples of Finished Products

Video Clip of the Operating Process

Additional Equipment for Full Operation:

Blade Sharpening Equipment

High-precision knife sharpening equipment, primarily used for sharpening cutting tools and fine grinding. The knife’s service life can be extended by 2-3 months.

Eight-Stage Reverse Osmosis Water Filter

| Manufacturer | China |

| City | Shanghai |

| Operating Capacity | 1000L/hour |

| Filtration Stages | 8 stage |

| Material | SUS 304 Stainless Steel |

| OSMOS Membrane | 4040 |

| Power Consumption | 2.5kw/hour |

| Voltage | 380V 50-60HZ |

| Cleaning Stages | Raw water tank → Raw water pump → Quartz sand filter → Activated carbon filter 2 → Cleaning agent dosing device → Precision filter → Primary booster pump → Primary reverse osmosis unit → Secondary booster pump → Reverse osmosis water membrane |

Screw Air Compressor

| Manufacturer | China |

| Air Pressure | 0.8MPA 8 bar |

| Air Flow | 2,3m³/min, 63db |

| Voltage | 380V 50-60Hz |

| Power Consumption | 15KV |

| Cooling Method | Air-cooled |

| Noise Level | 63db |

| Equipment Weight | 300kg |

Equipment Prices

| Preparation vessel for moistening and fragrance | 6000$ |

| 12-row moist napkin forming and wetting equipment and packing equipment | 97000$ |

| Robot plastic cap sealing and labeling machine (automatic) | 45150$ |

| Blade sharpening equipment: | 950$ |

| Eight-stage reverse osmosis water filter | 6900$ |

| Screw air compressor | 3800$ |

There are no reviews yet.