Paper processing

Special paper cones production line for textile and spinning

Availability:

Out of stock

Paper cones are a convenient solution for storing and using threads. Cones serve to keep the strands comfortable and compact, so that the strands do not tangle.

69,000$

Out of stock

General information

- Production speed: 50-60 PCs / min

- Total kW: 51.3 kw

- Wrapping equipment: 13.6 kw

- Storage equipment: 8 kw

- Drying equipment: 29.7 kw

- Number of workers: 4-5 people

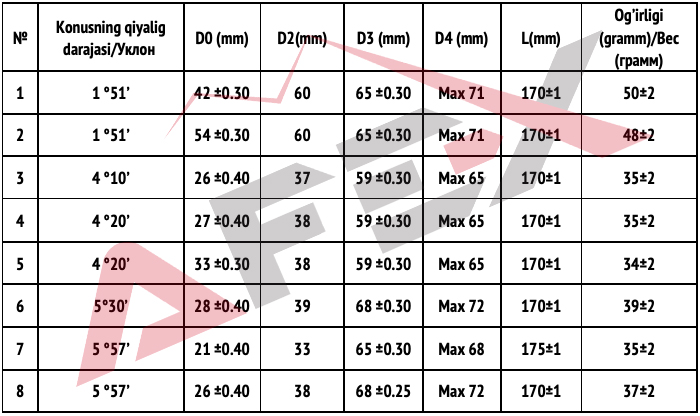

Types of paper cones and their description

Standard types of paper cones

- Paper cone 420

- Paper cone 557

- Paper cone 151

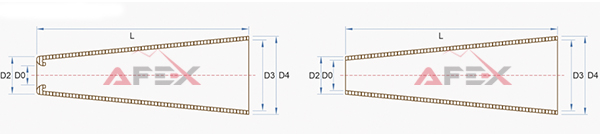

Drawing of the standard type of paper cones

Automatic paper cones production equipment

This equipment consists of several stages. The first to be delivered to the equipment is raw materials, a situation that is achieved in automatic revs. In the Keyiing stage, a colored pattern is omitted for the three parts of the cone. After that, the raw material is transferred to the cutting part and cut to the desired shape and size. Glue (clay) is poured into the cut raw material. In the next step, the equipment wraps the cartons to form the desired shape.

| Produced | China |

| Voltage | 380V |

| Total capacity | 13.6 kv |

| Production speed | 50-60 PCs / min |

| Finished product weight | 30-70 gr |

| Steering wheel | PLC management |

| Clamping style | 2-way gluing |

| Hardware basis | Polat ramali construction |

| Extension mode | Gear and chain transmission |

| Equipment size | 5850x2000x2100 mm |

| Equipment weight | 4000 kg |

Automatic paper cones drying equipment

| Produced | China |

| Voltage | 380V |

| Total capacity | 29.7 kv |

| Speed | 45-65 PCs / min |

| Heating configuration | Electric heater air oven |

| Equipment size | 7500x3000x1040 mm |

| Equipment weight | 2500 kg |

Cone bleaching equipment

| Produced | China |

| Voltage | 380V |

| All-union | 7.25 kv |

| Speed | 55-60 PCs / min |

| Equipment size | 2150x2710x1430 mm |

| Hardware turn | 1570 kg |

There are no reviews yet.