Waffle production line

Out of stock

The demand for food products in Uzbekistan is increasing. We can show the reason for this is the increase in the number of the population and the increase in the income of the population. In this place, as the offers on the market increase, the level of competition is becoming more difficult.

The demand for pastries and sweets in the markets of Uzbekistan remains high. AFEX-GROUP also offers a wide range of equipment in the food industry. We will start production of waffles with the help of this equipment.

144,400$

Out of stock

General information

Production capacity: 2500 kg/day

Total power: 120 KW

Voltage: 380V, 50Hz

Total line weight: 12 tons

Number of workers: 4-5

Total area: 18*8*4 (length*width*height)

Equipment list

A. Baking oven

B. Refrigeration equipment

C. Floor picking equipment

D. Cream spreading equipment

E. Vertical cooling section

F. Cutting equipment

G. Wafer separating-breaking equipment

H. Dough mixer

I. Mixer for cream

Now let’s get acquainted with the technical parameters of the equipment and the production process.

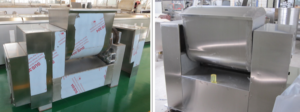

Mixer

First of all, we start the production process with a mixer. The mixer has automatic delivery and mixing systems. The equipment is made of metals that meet international standards and uses 1.2 mm SUS 304 stainless steel.

| Mixer | 95L |

| Continuity of mixing | 5-10 minutes |

| Voltage | 380V 50Hz |

| Power | 3.75 sq |

| General dimensions | 1300*660*930 mm |

| Weight | 200 kg |

Cream mixer

A cream mixer mixes sugar, butter and other products according to the recipe. The equipment is made of metals that meet international standards and uses SUS 304 stainless steel.

| Cream mixer | |

| Mixing capacity | 95 L |

| Voltage | 380V 50Hz |

| Power | 4kw |

| General dimensions | 1370*710*1400 mm |

| Weight | 700 kg |

Electric oven

The oven, of course, is the most basic equipment of this line. The fact that the oven is of high quality plays an important role in the quality output of the final products. The electric oven has the following features:

- All parts of the oven have heating circuits. Because of this, all parts of the oven heat up at the same time. Due to the use of high-quality metal, the equipment retains heat well.

- Small volume. The equipment is very different from the furnaces on the market, especially in terms of size. Its compact size can produce the required temperature and quality.

Oven The number of colips 27 The size of the culms 470*325 mm Error rate 1S Waffle block thickness 2.5-3.2 mm Initiating coleops Automatic Voltage 380V 50Hz Power 86 sq General dimensions 5540*1560*2320 mm Weight 9100 kg

Cooling conveyor

The function of this conveyor belt is to cool the wafers. You can see the working process in the following video.

| Cooling conveyor | |

| General dimensions | 2400*730*1360 mm |

| Power | 1kw |

| Weight | 130kg |

Cream spreading equipment

Spread the prepared cream on each sheet.

| Cream spreading equipment | |

| Power | 3,05 kw |

| Number of beds | 2,5 |

| General dimensions | 330*930*1230 mm |

| Weight | 850kg |

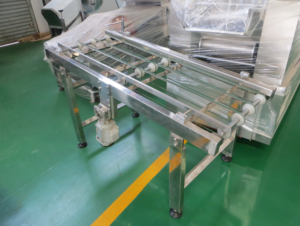

Conveyor belt

The equipment delivers wafers to further cooling and cutting equipment. Dimensions: 1150*700*950 mm.

Cutting equipment

The equipment can cut all required sizes without any difficulties.

| Cutting equipment | |

| Max. cutting height | 55mm |

| Min. cutting height | 20 mm |

| Power | 0,75 kw |

| General dimensions | 1740*2000*920 mm |

| Weight | 500 kg |

Grinding equipment

When we cut the wafers, lumps and excess parts are formed. The equipment shreds them and makes them usable again.

| Grinding equipment | |

| Power | 1,1 kw |

| General dimensions | 680*540*1200mm |

| Weight | 150 kg |

Packaging equipment

We prepare our finished products for sale with the help of packaging. We can use different types of film in the equipment. Package sizes can also be changed.

| Horizontal coding equipment | |

| Speed of operation | 40-230 pcs |

| Voltage | 220V 50Hz |

| Power | 1.7 sq |

| Product height | 70mm |

| The length of the package | 90-230 mm or 180-1350 mm |

| The width of the package | 40-175 mm |

| The size | 3770*670*1450mm |

| Weight | 550 kg |

| Price |

| Mixer |

| Cream mixer |

| Electric oven $105 4000 |

| Cooling conveyor |

| Cream spreading equipment |

| Conveyor belt |

| Cutting equipment |

| Grinding equipment $ 19500*2 $39000 |

There are no reviews yet.