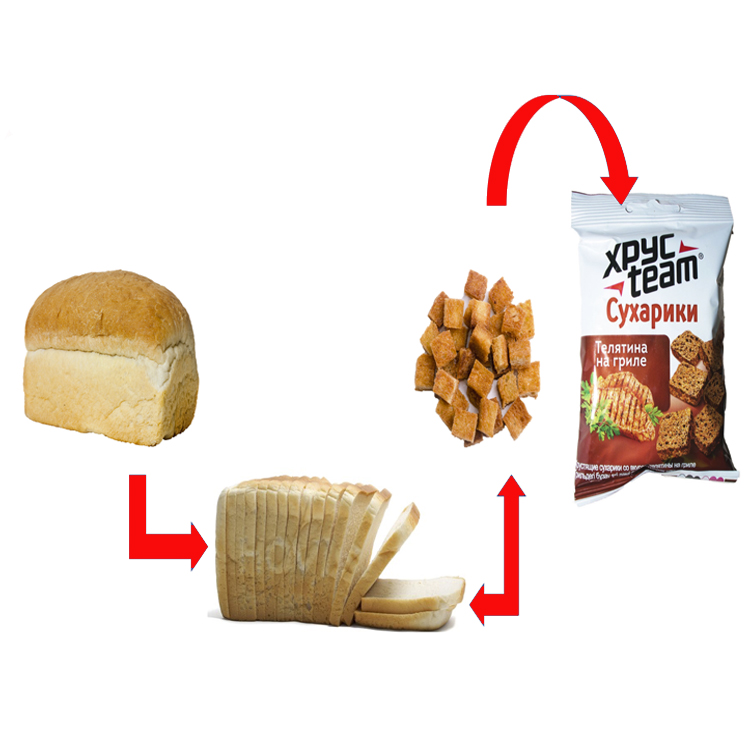

SUHARIKI (hard bread) production line from molded bread AF-L007

Out of stock

One of the snack products that both children and adults love to eat is dried bread, that is, sukariki. The demand for this product in our country is increasing every year. There are 2 different ways to produce this product – Extrusion and mold bread. Today we bring to your attention the mold bread production line. With this business, you can easily start at home and make quality products, that is, registered as a family business or a private enterprise. For your convenience, we have adapted all equipment to 220v voltage. In this line, the cost of the product is much cheaper, because you can choose one of two styles to produce the product.

Method 1: Buy freshly made bread, or make it yourself

Method 2: buy moldy bread at a lower price that is not more than 2 days old.

11,900$

Out of stock

First of all, you need to determine how to make a biscuit. Accordingly, you know exactly how to place the bread in the slicer. With our recommended line, you can produce products in the form of cubes and straws. Let’s take a look at the equipment we use to make our favorite sukharikiki with you, and then we’ll get to the account book stage.

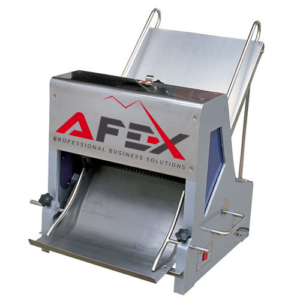

Bread Slicer (Step 1)

| Bread slicer | |

| Producing country | China |

| Voltage | 220V 50hz |

| power consumption | 1,5 kw/h |

| The size between saws | 8 mm |

| Bread cutting speed | 80-120 ps/h |

| Metal | Stainless metal + carbon |

After making the bread as shown above, you will need to place them in the second equipment. When you put it in the second bread slicer, it will have the shape you want.

BREAD cutting equipment (stage 2)

| BREAD cutting equipment (cube cutter) | |

| Producing country | China |

| Voltage | 220V 50hz |

| power consumption | 1,5 kw/h |

| Product cut length | 5 sm max |

| Bread cutting speed | 80-120 ps/h |

| Metal | Stainless metal + carbon |

| Raw cutting function for chips | is available |

After cutting the bread in the desired shape, they should be dried well. There have also been many suggestions as to whether it is possible to use a deck oven instead of the drying equipment we recommend. We want to write down what happens when you dry in a regular oven with the drying cabinet we recommend.

1) It is possible to dry breadcrumbs in an ordinary baking oven, but you cannot avoid the following disadvantages.

- Floor ovens provide heat only from the top and bottom, which causes the product to not dry evenly throughout.

- Due to the fact that the heat is given by the skins, the products placed close to the skins cause burns.

- Since the maximum capacity of the floor ovens is 9 trays, it will not match your production speed, and the cost of the product will increase due to its high electricity consumption.

Considering the above disadvantages, we recommend you a high capacity drying cabinet with high energy efficiency. This is the main stage that determines the quality of your product. In the drying equipment below, the product does not become too hard and does not burn.

P.S. You can easily use this drying cabinet to dry fruits and vegetables in summer.

| Product drying cabinet | |

| Producing country | China |

| Voltage | 220V 50hz |

| power consumption | 4,5 kw/h |

| Product cut length | 5 sm max |

| Bread cutting speed | 80-120 ps/h |

| Metal | Stainless metal + carbon |

| Copper coil fan speed | 1800r/min |

| The size | 59,6*42*146 sm |

| Number of pads | 32 |

| Padnos cherry size | 40*40sm |

| Heat dimension | 40*90C |

| Management system | numerical control |

Well-dried sukariki is put into the aromatizer to give it different flavors. Our technologists teach how much flavoring to add to the product, how long to mix it and other technological processes.

FLAVOR EQUIPMENT (AROMATIZER)

| Aromatizer for the product | |

| Producing country | China |

| Voltage | 220V 50hz |

| power consumption | 1,5 kw/h |

| Metal | Stainless metal |

| Speed | 35r/min |

| The size | S9,6*120*146sm |

We can easily pack our ready-to-eat products using our packaging equipment. And for packaging equipment, you can order a roll for packaging in the design you like. Our experts will help you in this regard as well. Currently, the price of 1 kg roll is around $7. Everyone is probably interested in the process of how much to earn from this work. Let’s make an account with you.

- 1 piece of mold bread wholesale price 1000 soums (550g)

- 1 piece of packaged product 35 gr

- The price of 1 pack is 80 soums

- We will review with you the production process of at least 50 pieces of bread in 1 hour.

- 50 pieces of bread*550g=27.5 kg

- 30% weight is lost in the process of building a 27.5 kg product and we are left with 19.25 kg of product

- We add 10% mass during the flavoring process and the total mass is 21.2 kg of product

- 21.2 kg=21200 gr / 33 gr 642 finished products

- 50000 soums for bread+80*642=51360 soums for packaging+corrugated box 33 soums for each product*642=21186 +24000 soums for dessert+3700*3=11 100 (3 workers)+ 2200 soms for electricity=159,846 soms

- 159,846 soums/642 products=248.9 soums

- 274 soums cost plus 10% tax and incidental expenses

- if 642 products are produced per hour, 6420 products are produced in 10 hours

If you add 76 soums of profit for yourself, 6420*76=487,920 soums (your net profit for one day)

Your monthly net profit of 13,174,000 soums (27 working days)

Wholesale price of your product: 350 soums

If the worker receives a monthly salary of 1 million soms each, 27 working days*10 hours per day

VERTICAL PACKAGING EQUIPMENT (Based on Capacitive Measurement)

| Coding equipment | |

| Producing country | China |

| Voltage | 220V 50hz |

| power consumption | 2,2 kw/h |

| Metal | Stainless metal |

| Speed | 50-60 |

| The size | S9,6*70*220 sm |

| Roll width max | 280mm |

Based on 0 reviews

Show reviews in all languages (1)

There are no reviews yet.