Dry plaster mix production line

Out of stock

One of the areas that shows the country’s development and power is, of course, the construction industry. In the most developed countries, great progress has been made in the field of construction. That is why the demand for construction materials remains high. AFEX GROUP will continue to offer its equipment in this direction (construction sector). You can produce dry plaster mix using our next production equipment. First of all, let’s get acquainted with the information about the product.

15,800$

Out of stock

About the dry plaster mix

Dry plaster mixture is raw materials mixed in dry form, to which special additives and polymers can be added for specific purposes in construction. The plaster mixture meets the excellent technical characteristics that meet the requirements common in the current construction industry.

It is often prepared in the form of powder or granules in special factories and delivered to the construction site. After mixing with enough water, it can be used directly. Dry plaster mixture usually consists of lime, cement, sand and minerals. Other types of raw materials are added for use in other fields and purposes. For example, this mixture can be added to plaster and concrete, it can be used for external and internal facades, for gluing and patching tiles. Therefore, depending on the field of application, the list and proportion of raw materials changes.

General information

Production capacity: 1-3 tons/hour

Number of workers: 2-3

Total power: 20kw

Required area: 50 square meters

Main raw materials: lime, cement, sand

Equipment list

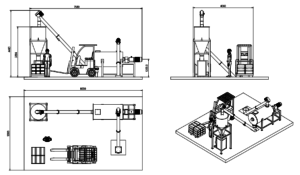

Our production line includes the following equipment:

- Screw conveyor (2 sets)

- Spiral mixer

- Hopper for finished product

- Packaging equipment

- Compressor

The production process does not consist of multi-stage and complex processes. In this, all the finished raw materials are mixed and then packed. For this reason, it will be enough for us to familiarize ourselves with the equipment itself.

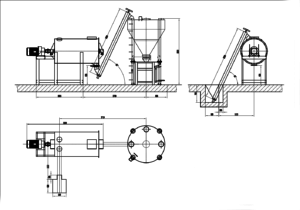

Screw conveyor

Delivers various raw materials to the mixer. And when the production process comes to an end, it transports the finished product to the tank. 2 sets of these conveyors are provided.

| Screw conveyor | |

| Spiral diameter | 140 mm |

| The equipment is diametric | 165mm |

| Working angle | 0-60 |

| Length | 3m |

| Working capacity | 3-5 tonna/h |

| Power | 3 kw |

Spiral mixer

We mix all the raw materials. The equipment has a large capacity and prepares the mixture in good quality. You can familiarize yourself with the technical indicators in the table below.

| Spiral mixer | |

| Capacity | 1,65m3 |

| Efficiency | 600-1000 kg/Cycle |

| Cycle duration | 10-15 min |

| Power | 7,5 kw |

| General dimensions | 3140*980*1400mm |

| General dimensions | 1200 kg |

Hopper for finished product

Equipment diameter: 1.6m. Its length is 2.8 m. Due to the fact that the equipment is made of stainless steel, it can serve you for a long time. When this hopper is connected to the packaging equipment, the automatic packaging process begins.

Packaging equipment

We pack the finished products and they are ready for sale.

| Packaging equipment | |

| Packing weight | 20-50 kg |

| Power | 3 kw |

| General dimensions | 700*1100*1200mm |

| Weight | 180kg |

Video from the production process

There are no reviews yet.