Mattress production line

Out of stock

AFEX-GROUP company offers modern equipment necessary for the production of Bonell mattresses, popular and popular in our country, to start mattress production.

67,000$

Out of stock

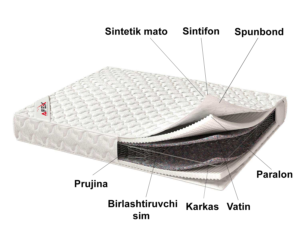

Bonell mattress production technology

In the production of bedroom furniture, mattresses made of traditional soft steel wire elastic springs are becoming more modern in terms of design. Production of products includes the following general work processes. Bonell mattress manufacturing processes begin with spring production and assembly. Then, the surface of the mattress is made of fabric combined with fabric and synthetic fiber. At the last stage, depending on the type and purpose of the combined spring block and the mattress, various fillers (foam rubber, latex, fabric waste, thermal felt, etc.) are prepared for the surface part, and the side part is combined with hardened fabrics and brought to the state of the finished product. .

Required raw materials:

Jacquard woven synthetic or cotton fabric; homeland; spunbond; strap; paralon or polyurethane foam.

High carbon steel wire with a diameter of 2.2 mm and a thickness of 5-6 mm.

Necessary infrastructures to start the activity:

Required area; Should not be less than 120 m².

Electric energy; 19 KW/220 and 380 V.

Number of workers; 8-12 people.

Equipment needed for this activity:

1. Bonell spring equipment.

2. Bonell spring assembly equipment.

3. Zigzag equipment.

4. Dimension cutting equipment.

5. Frame bending equipment.

6. Pneumatic clamping equipment.

7. Tape sewing machine.

8. Computer bladder machine.

9. Connecting sewing machine.

10. Air compressor.

Bonell spring equipment

Bonell spring equipment – The equipment has the ability to automatically make, weld, and cut springs. Depending on the diameter of the steel wire, it can be adjusted from 1.8 to 2.5 mm. The equipment has a production capacity of 55 pieces of bonell springs for 1 minute.

| Technical indicator | |

| Diametric of steel wire | 1.8-2.4 mm |

| The outer diameter of the ring | 65-85mm |

| Spring rate | 80-200mm |

| Production speed | 55 springs/min |

| Spring rotation | 4-8 |

| Voltage | 380V |

| Power | 4.5KV |

| Size | 2280*1100*1660mm |

| Weight | 1100 kg |

Bonell spring harvesting equipment

Bonell spring assembly equipment – In the equipment, bonell springs are manually placed in a specially designated part, and then automatically coiled with steel wire.

| Technical indicator | |

| Spring width | 2 m |

| Diametric of spiral steel wire | 1.3-1.6mm |

| Spring length | 80-220mm |

| Wire diameter | 1.8-2.5mm |

| Voltage | 380V |

| Power | 4.5KV |

| Size | 3100*960*1900mm |

| Weight | 950 kg |

Zigzag equipment

Zigzag equipment–the equipment works on the technology of automatic non-stop wire unwinding, forming and winding. The diameter of the steel wire is 2.5- 4.3 mm, and the wire is bent to form a zigzag appearance.

| Technical indicator | |

| Spring width | 45-70 m m |

| Diametric of spiral steel wire | 20-50mm |

| Diametric of the spring wire | 2,5-4,3mm |

| Opportunity | 38-180 hills/min |

| Power | 380V50Hz |

| Size | 1340*720*1900mm |

| Weight | 800 kg |

Equipment for cutting to size

Sizing equipment – this equipment straightens and cuts steel wires with a diameter of 3-6 mm. This equipment also has the option of automatic non-stop operation in fixed sizes. In the equipment, the wires cut to size are processed in the frame bending equipment.

| Technical indicator | |

| Frame length | 7800mm |

| Wire diameter | 3-60mm |

| Voltage | 380V |

| Speed | 1400 rpm |

| Power | 4kv |

| Size | 1460*495*1335 mm |

| Weight | 675 kg |

Frame bending equipment

Frame bending equipment – this device bends the side frames that support the mattress in the specified dimensions to form a frame. The equipment works with air cylinders.

| Technical indicator | |

| Wire diameter | 3-5 mm |

| Air pressure | 1.0 MPa |

| Frame width | 800-1800mm |

| Frame length | 1800-2300 mm |

| Opportunities | 1000 pieces/hour |

| Size | 2500*700*700mm |

| Weight | 200 kg |

Pneumatic clamping equipment

Pneumatic clamping device – a device that connects the carcass part with concentrated bonell springs, with special clamping details. The equipment works with an air compressor. In the production of bonell mattresses, this equipment completes the production processes of products with steel parts.

| Technical indicator | |

| Opportunity | 40-50 pcs |

| Gross weight | 4.03 kg |

| Net weight | 3.3 kg |

| Size | 410*210*90mm |

Tape sewing machine

Ribbon Sewing Machine- The side fabrics connecting the upper and lower parts can be combined with ribbons or other types of fabric to create a new design. Machine sewing can be done automatically without interruption.

| Technical indicator | |

| Knitting width | 10(14.20)*4.8(6.4)mm |

| Side fabric width | 100-360mm |

| Sewing speed | 10-14.4m/min |

| Voltage | 380V |

| Power | 0.58KV |

| Size(L*W) | 3200*1600mm |

| Weight | 520KG |

Computerized bladder machine

Computer-aided sewing machine- This sewing machine automatically executes the sewing work specified on the basis of the drawing created by the computer. Bonell is adapted to the production possibilities of mattresses.

| Technical indicator | |

| Length | 2-7mm |

| Needle speed | 500-2500 needles/min |

| Speed | 2000 rpm |

| Stitch size | 2.0*2.2 m |

| The size of the fabric | 2.3*2.5 m |

| Voltage | 220V, 50Hz |

| Power | 1.5KV |

| Size | 2800*2900*1400 mm |

| Weight | 700 kg |

Joint sewing machine

Connecting sewing machine – a modern machine that sews upper and lower seams with a special tape. This machine can be adjusted to a size of 26 cm.

| Technical indicator | |

| Range | 260 mm |

| Voltage | 220V, 50Hz |

| Size | 1930*1500*800mm |

| Weight | 464 kg |

Air compressor

Air Compressor – Auxiliary device for frame bending equipment and pneumatic crimping equipment.

| Technical indicator | |

| Pressure | 0.8 Mpa |

| Cylinder(diametric*quantity) | 90mm*3 |

| Gas volume | 250L |

| Packaging size | 1630*670*1150mm |

| Gross weight | 320 kg |

| Net weight | 270 kg |

| Tension | 380V |

| Power | 7.5KV |

| Size | 1530*520*1130 |

Video footage of the process

Based on 0 reviews

Show reviews in all languages (1)

There are no reviews yet.