Automatic candy production line

Out of stock

Of course, the youth of each of us did not pass without sweets, chocolates and candies. There are some such products that are still available for sale and have not lost their customers. You can see one of such products in the following pictures.

124,000$

Out of stock

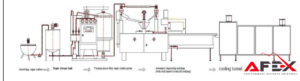

AFEX-GROUP company offers the production of this type of candies using the following equipment. Below you can see general information about this production line.

General information

Production capacity: 200 L/h

Production capacity: 20 kw/h

Required area size: 70-80 square meters. meters (at least 20 meters long)

Number of workers: 4-5

Number of molds: 4-5 types

List of raw materials: sugar, syrup, paste, water, colors

Equipment list

- Mixer

- Sugar melting equipment

- Pumps

- Vacuum oven

- Pouring equipment

- Cooling tunnel

- Control Panel

- Molds

Production process

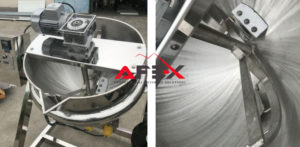

Mixer

| Capacity | 100 L |

| Voltage | 380 V |

| Power | 24 KW/h |

| Heating way | Through thermal oil |

| Dimensions | 1280*1050*1300mm |

| Theft | 250 kg |

| Contains | Reducer, motor, agitator |

Sugar melting equipment

| Capacity | 200 L |

| Dimensions | F 800*1500 mm |

| Voltage | 380V 50Hz |

| Power | 0.75 Kv |

| Vapor pressure | 0.4 Mpa |

Pump

| Diameter | 25mm |

| Speed | 0.32 L/r |

| Capacity | 3m3/hour |

| Power | 1.1 sq/h |

| Dimensions | 980*350*400mm |

| Task: | Delivery of syrup to dry equipment |

Vacuum oven

| Model | AFX-300 |

| Vapor pressure | 0.5-0.8 Mpa |

| Total power | 28 Kv/h |

| General dimensions | 2300*2500*2350 mm |

| Function | Removes water from syrup to improve product quality |

Pouring equipment and cooling tunnel

| Capacity | 250-300 kg/h |

| Voltage | 380 V |

| Total power | 17 Kv/h |

| General dimensions | 11000*19000*2600mm |

| Material | Stainless metal |

| Control Panel | PLC control panel |

Contents:

1) Double row servo control injection molding machine 1 set

2) casting pot 1 set

3) Molds 1 set

4) Casting part

5) Blender of fragrances and by-products (two sets)

6) Metering pump (four sets)

7) Cooling section: 12P

8) Servo controller 1 set

9) Refrigerator 1 set

10) Cooling conveyor 1 set

11) Release from the mold 1 set

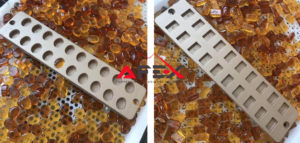

Molds

Video from the production process

Video from the production process

There are no reviews yet.