Agraf (podves) production line

Out of stock

Day by day, modern technologies enter every part and field of our life

is coming Our demand for them is increasing, not decreasing at all.

Examples of these are food, car service, wood and metal processing,

we can say packaging, service areas. It is developing so rapidly

one of the sectors is, of course, the construction sector.

12,700$

Out of stock

Advantages

1 Light

2 Production does not require much effort

3 Comfortable

4 Durable

5 Multi-functional

6 Low cost

7 Takes up little space

As you can see, agraf has a lot of advantages and its in the field of construction

the place is incomparable. That’s why we offer you a business that brings you high income

we offer. We hope that through this business, our people will be cheap and of good quality

you provide with podves and therefore, as a result, your income is short

you will be able to increase in a large amount within a period of time. Below is this production

You can get detailed information about the line.

We need equipment, raw materials and space

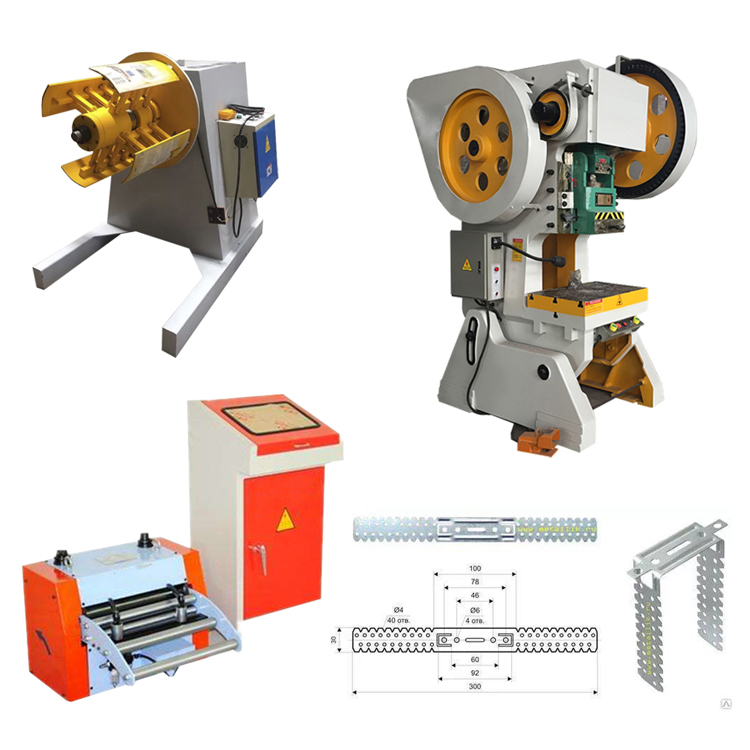

We need the following set of equipment for the production of agraf (podves):

1 Metal roll delivery equipment

2 Metal roll leveling equipment

3 Mechanical press

You use metal as raw material. For this, a metal round roll

it is advisable to wrap it in the form of Metal roll in Tashkent at an average price

You can find 1 ton for 10 million soums. We remind you that this price is average

taken into account. Price changes in relation to the quality of raw materials and the place of purchase

possible

This set of equipment does not require a large area from you. Sequence the equipment

When you place it, it takes up about 10m. Therefore, the room in relation to these dimensions

your preparation will be appropriate.

Due to the automation of all processes in the equipment, the processes in the equipment, raw

it is enough to hire 2 workers in order to control materials and products.

Production process

Let’s talk with you about the whole process of the agraf(podves) production line

let’s get acquainted in detail.

Metal roll delivery equipment

At this stage, we place the finished coil of metal into the delivery equipment. This

delivery of the metal roll to the servo feeder (straightening equipment) through the rotation of the equipment

will give.

| Metal roll delivery equipment | |

| Material thickness | 2 mm |

| Latitude range | 450mm-530mm |

| Kalava weight capacity | 2000 kg |

| Speed | 15m/min |

| Kalava external diametric | Max 1200mm |

| Maximum bed width | 400 mm |

| Main shaft | 40 Cr |

| Equipment weight | 800 kg |

Due to the fact that all parts of the supplier’s equipment are made of steel, heavy metals

it serves without difficulty and continuously when lifting.

Function: to the diameter of the metal roll due to the hydraulic parts placed in the equipment

it is possible to expand and narrow the diameter of the part located on the equipment.

Corrective equipment

In the next step, after the roll metal is delivered, the servo feeder equipment

The roll straightens the metal and makes it ready for the press machine. To the equipment

as an addition, a display is installed. Settings and process through a modern display

you can change and control its progress

| Corrective equipment | |

| Maximum operating speed | 400 mm |

| Maximum working length | 9999 mm |

| Material thickness | 0.2-3.2mm |

| Mold height | 70-170mm |

| Motor | AC1.3 |

Corrective equipment has the following characteristics:

1 Products of different thicknesses and lengths can be used

2 High speed and can work for a long time, improved speed and accuracy

3 Panel control, easy and clear

4 Pneumatic process, error free

5 Mechanization is also possible according to the customer’s request

6 The maximum speed is 20m/min

Corrective equipment structure:

1 The latest servo motor is used. This, in turn, requires a process

minimizes area and test time

2 Decoder with high sensitivity

3 Low noise, less oil required

4 It may occur during delivery due to the motor being located inside the equipment

prevents various damage.

5 YASKAWA brand motor is used in the equipment

Mechanical Press Equipment

At the last stage, the finished roll is pressed using a mechanical press

based on the entered dimensions, makes slits in the metal and cuts. Equipment pressing

works according to the mechanism.

| Mechanical Press equipment | |

| Nominal pressure | 400KN |

| Stroke speed | 45/min |

| Length of vertical columns | 340mm |

| The distance between the center of the slider and the hardware | 250mm |

| Desktop thickness | 65 mm |

| Electric motor power | 5.5kw |

| Weight | 3600 kg |

| № | Parts | Produced | Configuration |

| 1 | Main motor | China | Standard |

| 2 | Electric part | France | Standard |

| 3 | Security barrier | France | Standard |

| 4 | Mechanical lubrication | China | Standard |

| 5 | Pedal | China | Optional |

| 6 | Photoelectric protection | China | Optional |

| 7 | Main motor | Germany | Optional |

| 8 | Oiling | China | Optional |

| 9 | Safety standard | CE |

Film from the production process

This Press equipment is made of metal construction. Heavy weight and special design

thanks to which the equipment can press up to 40 tons.

Product thickness: 0.3-1.0mm

Product length: 300mm

Production capacity: 70-80 pieces/minute

The mechanisms of the equipment are made of cast steel, and the teeth of the mechanism are the same.

The hardware disk is also made of solid steel. The processes in this equipment are gentle, easy and

serves a quick transition.

The mechanical power press is made of high grade cast iron and is sufficient for pressing work

balanced to store and release power.

The oil-lubrication system is specially developed for the equipment, and the equipment is pushed

ensures continuous operation of surface parts.

| Prices | |

| Delivery equipment | 11 900$ |

| Corrective equipment | |

| Mechanical Press equipment | |

Based on 0 reviews

Show reviews in all languages (1)

Be the first to review “Agraf (podves) production line” Cancel reply

Related products

-

Metalworking equipment

AF-N6 Metal tube winding trace equipment

0 out of 5(0)The advantages of the metal pipe wrapping machine are: simple operation, high production efficiency, stable forming effect, high speed and other features.

Pipe materials: stainless steel/copper/carbon steel/iron/galvanized/aluminum etc.

Application: Pipes designed for furniture, construction and other industries.

SKU: n/a11,000$ -

Metalworking equipment, Solution product lines

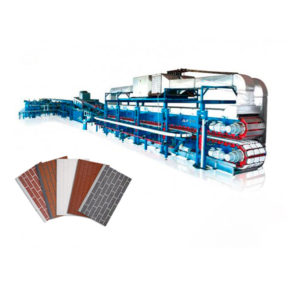

Production line of PU insulating decor products for walls

Metalworking equipment, Solution product lines

Metalworking equipment, Solution product linesProduction line of PU insulating decor products for walls

0 out of 5(0)This production line:

The whole line adopts the first line brand touch screen, sine frequency converter. Features: Real-time monitoring and data display of the entire line; The equipment is easy to use, can do start and pause, automatic and manual mode change.

SKU: n/a237,000$ -

Metalworking equipment

Metal cylinder containers production line

0 out of 5(0)“AFEX-GROUP” offers a production line of metal containers with hooks from 1 liter to 5 liters with high profit for our entrepreneurs. For our customers who purchase this line, our company will provide close practical support in starting this activity.

SKU: n/a118,000$ -

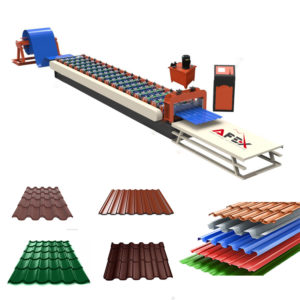

Metalworking equipment, Solution product lines

Equipment for the production of metal tiles (profnastil).

Metalworking equipment, Solution product lines

Metalworking equipment, Solution product linesEquipment for the production of metal tiles (profnastil).

Rated 5.00 out of 5(0)Profnastil products are an integral part of construction. Almost all local constructions have demand for profnastil products, taking this into account, the company “AFEX-GROUP” offers you profnastil production equipment below.

SKU: n/a14,700$

There are no reviews yet.