Waffle production line for ice cream AF-L31

Out of stock

As the days begin to warm, the era of the ice cream business begins. In general, the production of ice cream and related products has always been one of the most profitable products. Today we will introduce you to a small but very profitable business.

15,700$

Out of stock

This machine can produce the rolled wafer for ice cream, and you can also produce a new type of plate shape and waffle tube for ball ice cream. AFEX-GROUP always introduces the best businesses to you, and this time it is the same. Let’s first look at the resources required for the operation of our equipment.

- Premises for building or production: one room of not less than 50m2

- Work force: 2 people

- Power supply and consumption: 380v 50hz 18kw/h

- Gas supply: No

- Raw materials: 100% local raw materials

- Field of application: Food

- Daily production volume: 10,000-12,000 products in 10 hours

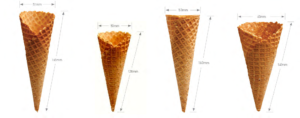

The only thing you need to focus on when you’re doing your market research is determining what size waffles are most popular in your area. To do this, you need to measure the diameter of the upper part of the rolled waffle and its length.

MIXER FOR LIQUID DOUGH PREPARATION 60L

First of all, the necessary products (flour, sugar, water, etc.) for making ice cream waffles are carefully prepared in a mixer. The main task of the equipment is to thoroughly mix the products and bring them to the desired liquid state. If it is not well mixed, it may have trouble passing through the special casting equipment.

| MIXER FOR LIQUID DOUGH PREPARATION 60L | |

| Produced | China |

| City | Shanzai |

| Voltage | 220V50Hz |

| Speed | In 2 different modes |

| Sigimi | 60 l |

| Material | stainless metal sus304 |

| Weight | 70 kg |

| The size | 500*700*1000mm |

CASTING EQUIPMENT FOR LIQUID DOUGH

This equipment is used to pour the liquid dough prepared in a mixer into the baking part at the same weight. A compressor is necessary for the equipment to work, and it starts when a special sensor gives a command.

| CASTING EQUIPMENT FOR LIQUID DOUGH | |

| Produced | China |

| City | Shanzai |

| Voltage | 220V50Hz |

| Speed | Using a special sensor |

| Sigimi | 30 l |

| Material | stainless metal sus304 |

| Weight | 70 kg |

| The size | 500*600*1200mm |

| Type of operation | With the help of air |

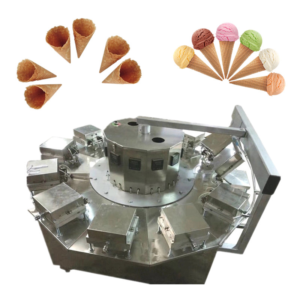

CONTINUOUS WAFFLE PREPARATION EQUIPMENT 15 pcs

Our equipment consists of 15 electric waffle irons arranged in a circle. The speed of the equipment and the heat level of each waffle cooking section can be controlled separately. By changing the equipment baking molds, the patterns on the surface of the waffle can be changed. The equipment is made of stainless steel so that it meets all hygienic requirements. The casting equipment can produce 1000-1200 pieces of product per hour.

| CONTINUOUS WAFFLE PREPARATION EQUIPMENT 15 pcs | |

| Produced | China |

| City | Shanzai |

| Voltage | 350V50Hz |

| Speed | Using a special sensor |

| Sigimi | 30 l |

| Material | stainless metal sus304 |

| Weight | 800 kg |

| The size | 1800*1380*1500mm |

| Type of operation | With the help of air |

| Number of cooking pods | 15 |

EQUIPMENT FOR PACKING WAFFLES IN THE SHAPE OF A CONE

With this equipment, round shaped wafers are made into a conical shape. The equipment has two winding parts, which is an indication of the high speed of operation of the equipment. A mold is ordered for the machine according to the customer’s request, which determines the size of the final product.

| EQUIPMENT FOR PACKING WAFFLES IN THE SHAPE OF A CONE | |

| Produced | China |

| City | Shanghai |

| Speed | Using a special sensor |

| Speed of operation | 1000-1200 pieces/hour |

| Material | Stainless metal sus304 |

| Weight | 130 kg |

| The size | 600*1100*1200 mm |

| Type of operation | Air and electricity |

| Voltage | 220V50Hz |

| The part that gives | 2 pcs |

AIR COMPRESSOR 30L

An air compressor is used to supply air to cylinders during product pouring and molding.

There are no reviews yet.