PP, PS film production line

Out of stock

In the last decade, the increase in packaging requirements, the emergence of large retailers, requires the production of new types of films with different compositions and properties. There are many types of polymer films, every year the packaging market offers new modifications with improved properties.

69,000$

Out of stock

“AFEX-GROUP” will continue to present new projects and technologies for entrepreneurs of our country. PP, PS polymer film production business; You can see how profitable this activity is, the high demand for this product in the markets of our country, and the products that are imported in large quantities from foreign countries.

PP, PS polymer films are mainly used for thermoforming disposable containers and packaging. Brief information on PP, PS polymer film products and their differences.

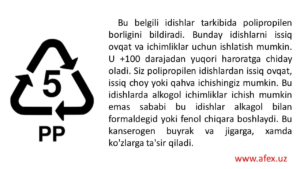

Needed, plastic numbering for consumer and producer

Polypropylene (PP) is the most modern, environmentally friendly, highly recyclable thermoforming material. High and low temperature resistance, light and manufacturable. Polypropylene – transparent, glossy surface, oil resistance, differs from polyethylene in low temperature resistance. Depending on the desired properties, its properties can be adjusted by adding suitable additives. Polypropylene film is used for hot drinks, food and dairy products, egg containers, seedlings and flower trays, various pastries and sweets, confectionery, packaging.

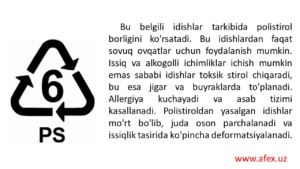

Needed, plastic numbering for consumer and producer

Polystyrene (PS) film- In addition to transparency, rigidity and dimensional stability, the advantages of the material are its cheapness. The popularity of the product is due to its low weight, ease of processing, high quality, low temperature and resistance to aggressive environment. Polystyrene film is used for non-hot drinks, food and dairy products, egg containers, seedlings and flower pots, various baking and sweets, confectionery, packaging.

Necessary infrastructures to start operations

Required area; 12 x 3 meters, not less than 36 m².

Electric energy; 140 KW/380 V.

Number of workers; 1-2 people.

All production industries require water as the main source.

The range of equipment in the line

1. Raw material mixer.

2. Screw conveyor.

3. Extruder.

4. Calendar (3 reels)

5. Temperature control system.

6. Wrapping equipment.

7. Water tower.

8. Plastic shredder.

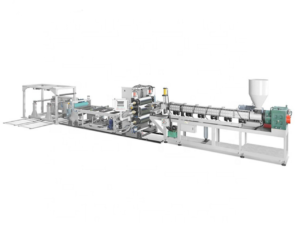

You can find out about the production technology of the line in the picture below.

The production capacity of this line is 150-200 kg per hour. We will briefly explain the production processes of the line products with the help of the equipment included in the line.

The mixer is made of stainless steel. Initially, two or more colored raw materials are mixed in the production of color film using a mixer.

| Mixer | |

| Model | TJB-1100 |

| Capacity | 125 kg |

| Production | 500 kg/h |

| Bunker | 1100 mm |

| Voltage | 380V 50Hz |

| Power | 2.2 sq |

| General dimensions | 1100*1100*1050 mm |

| Weight | 125 kg |

Screw conveyor – this device acts as a supplier of raw materials to the upper feeding part of the Extruder.

| Screw conveyor | |

| Model | ZD-2000 |

| Speed | 200kg/h |

| Rated power | 2,3kw |

| Power source | 380v50hz |

| General dimensions | 900*900*700 mm |

| Stainless steel pipe size | L1400*133 mm |

| Weight | 125 kg |

Composition of Extrusion line in production of products; It consists of extruder, calendering, temperature holding system, waste wrapper and roll film wrapper. Extruder PP, PS type plastic raw materials are melted at high temperature after being loaded. Melted granules are compressed with the help of an auger into a formation with a width of 670 mm and a thickness of 0.3-2 mm. Formed films are cut to a specific size in a 3-roll calendering section. Then, after passing through the temperature control system, the waste upper part of the two edges of the film with the specified dimensions is wrapped. Then the films of the specified size are automatically wound in the roll case. The equipment is controlled by a computerized PLC control panel.

| Ekstruder liniya | |

| Model | TJ-670 |

| Raw material | PP, PS |

| Max list width | 670 mm |

| Sheet thickness range | 0.3-2.0 mm |

| Screw stem diameter | 110 mm |

| Main motor | 45 sq |

| Production speed | 150-200 kg/h |

| Rated power | 110 sq |

| Power supply | AC 380V 50Hz |

| Size | L11000*2000*1800 mm |

| Weight | 5.8 T |

Water tower – An auxiliary device for the operation of equipment through a pump, in cooling the water temperature and ensuring its moderation.

| Water tower | |

| Height | 2300 mm |

| Diameter | 1800 mm |

| Motor power | 1,1 kw |

| Power source | 380v50hz |

| Weight | 100 kg |

Plastic shredder – shreds plastic waste for recycling.

| Grinding equipment | |

| Model | TP-650 |

| Speed | 300 kg/h |

| Diameter | 10.5 mm |

| Twist teeth | 6 |

| Motor power | 15 sq |

| Voltage | 380V 50Hz |

| General dimensions | 1600*1200*2000 mm |

| Weight | 500 kg |

There are no reviews yet.