Ear cleaning stick production line

Out of stock

Members of the AFEX-GROUP team will continue to offer you mutually beneficial and profitable types of business. Our next production line is also one of the most profitable areas. Products can be used in everyday life, childcare, medicine and cosmetics. With the help of our equipment, you can produce ear cleaning sticks in different sizes and shapes (appearance).

47,000$

Out of stock

General information

Production speed: 1200 pieces/min

Voltage: 380V

Power: 13 kw/h

Buffer type: one-way / two-way

Type of sticks: plastic, paper, wood, bamboo

Equipment dimensions: 7806*940*1790 mm

Types of packaging: packaging equipment varies

Cotton Head Type: Patterns vary

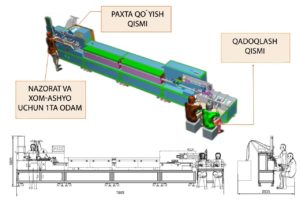

Location scheme

An area of 8 meters in length and 1 meter in width is required for placing the equipment. In general, 30-40 square meters will be enough.

Production process

The first part

To understand the production process, first of all, it is necessary to familiarize yourself with the parts of the equipment.

- Glue pump. Delivers glue to the mold.

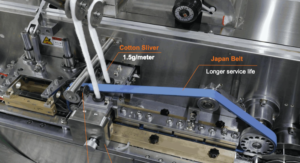

- Cotton head adjustment section. In this part, how thick and heavy the cotton should be wrapped is adjusted.

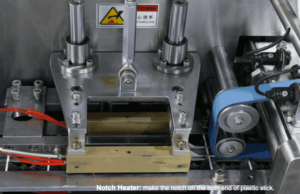

- Part of processing sticks. The function of this part is twofold: if it is a plastic stick, it is to bend it so that it sticks well, or to apply glue to bamboo/paper, wooden sticks.

- Cuts cotton.

- Mold. It determines the type of wrapping by changing the mold.

Samples from the production process

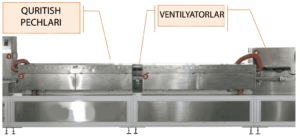

The second part

The main function of this equipment is to remove moisture from the finished products.

The third part

- Supplier part. After the product is 100% ready, it is necessary to pack it. A special unit automatically supplies the sticks to the packaging equipment, while complying with hygienic requirements.

- Packaging equipment. The packaging equipment is located at the end of the production line. 1 packaging equipment is included in the package of the line. If another type of packaging is needed, packaging equipment will be added for an additional fee.

There are no reviews yet.