Corrugated box production line AF-L028

Out of stock

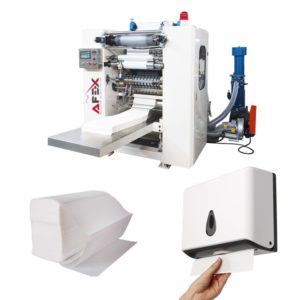

Corrugated boxes are mainly used to ensure that any of your products reach the customer in good quality. It is safe to say that this business has become a trend in the 21st century. Corrugated boxes are used to protect them from deformation without affecting product quality. Corrugated boxes can be 2, 3, 5 and 7 layers depending on the field of use. The most common types are 2- and 3-layer types. We decided to recommend the semi-automatic version of our production line, which we offer you below, so that most entrepreneurs have the opportunity to buy it. With the help of the equipment, you can produce corrugated boxes with a smooth surface on one side. The equipment is designed to work with a kraft roll with a width of 1400 mm. We also have the option to bring in fully automatic production lines for our customers who want to further expand production or set up large-scale production.

109,700$

Out of stock

REQUIRED SUPPLY FOR THE LINE

Building: production area of not less than 150 m2

Raw material: Kraft roll width 1400mm

Work force: 5 people

Voltage: 3 phase 380v 50hz

Gas supply: Not required

Water supply: Not required

Sewage: Not required

CONVEYOR EQUIPMENT FOR KRAFT PAPER ROLL

This equipment is designed to work with two rolls at the same time. Kraft paper is used for corrugation and product delivery for gluing part. It has the ability to lift the roll from the ground during operation. This eliminates the need to carry a heavy roll.

| Transfer equipment for kraft paper roll | |

| Produced | China |

| Voltage | 380V50hz |

| Power consumption | 3kw/h |

| Working width | 1400 mm |

| Maximum weight bearing capacity | 2T |

| Size | 4300*1600*1700 mm |

| Weight | 1300 kg |

GLUING EQUIPMENT FOR CORRUGATED PRINTING ON KRAFT ROLLS

The main function of the equipment is to make a special mark on the incoming roll and connect both layers using glue. In order for the glue to dry quickly, we chose the method of drying the equipment using an electric roller instead of steam. This allows you to produce a high-quality product without additional costs and additional equipment.

| Corrugated gluing machine for kraft roll | |

| Produced | China |

| Voltage | 380V50hz |

| Power consumption | 3kw/h |

| Working width | 1400 mm |

| Speed of operation | 30-40m/min |

| Size | 2600*1300*1500 mm |

| Weight | 3700 kg |

| Type of drying | Using an electric heating shaft |

| Paper transit method | Using vacuum technology |

| Automatic lubrication system | There is |

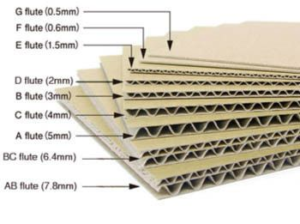

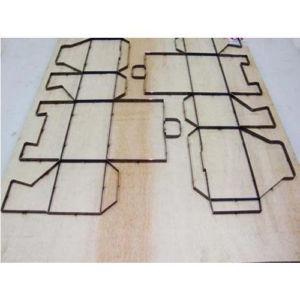

You can order from us by choosing one of the sizes shown in this picture after you have determined which size of corrugated sheets you are interested in. Please note that this size is the size of the footprints on the bent part of your sheet, and to change them, you will need to order an additional shaft. We advise you to order carefully.

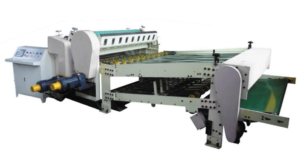

COMPUTERIZED CORRUGATED SHEET CUTTING EQUIPMENT

This part is used to cut the corrugated roll to the required size and divide it into corrugated sheets according to your order. The cutting size is entered into the computer by the controller, and the moving kraft roll is measured by the laser sensors and cut by the cutting drum. The vertical and horizontal cutting blades you need do not require a lot of experience because they work automatically.

| Computerized corrugated sheet cutting equipment | |

| Produced | China |

| Voltage | 380V50hz |

| Power consumption | 3kw/h |

| Working width | 1400 mm |

| Speed of operation | 30-40m/min |

| Size | 2500*4000*1800mm |

| Weight | 2500 kg |

| Paper transit method | Using PXV tape |

| Automatic lubrication system | There is |

2 COLOR FLEX PRINTER WITH CUTTING ROLLER

This equipment has an improved paper receiving function and a part to transfer paper to the printer. Corrugated sheets are lowered into the image through drums. A high-tech process takes place in the equipment, which allows construction in a short time. If your box design is just a matter of snapping the sides together, this printer will print the prints for you. Also, the equipment is used to cut the cutting parts adjacent to the edges of the sheet. In such cases, you will not need to come to the aid of other techniques. This printer is designed for 0-12mm thickness corrugated boxes.

| 2 color flex printer with cutter roller | |

| Produced | China |

| Voltage | 380V50hz |

| Power consumption | 6kw/h |

| Working width | 1400 mm |

| Speed of operation | 0-60m/min |

| Size | 3000*3700*1700mm |

| Weight | 7000 kg |

| Printing error | 0,5mm |

| Printer shaft diametric | 480mm% |

| Minimum corrugated sheet size | 350mm*500mm |

| Maximum print size | 1400*2300mm |

CORRUGATED BOX STAPLER EQUIPMENT

Corrugated boxes are attached using glue or staplers depending on the area of use. The weight of the product placed in the box and the size of the box play an important role. The equipment is distinguished from other types by its quick stapler. According to the thickness of the corrugation, the length of the axis is adjusted. The distance between staplers is adjusted according to the weight of the load.

| Corrugated box stapler equipment | |

| Produced | China |

| Voltage | 380v50hz |

| Power consumption | 0.3kw/h |

| Working width | 1200mm |

| Speed of operation | 250 staplers/min |

| Size | 1700*400*1820mm |

| Weight | 350 kg |

| Box thickness | For corrugated boxes with 2,3,5,7 layers |

GLUING EQUIPMENT FOR CORRUGATED BOXES

Boxes that cannot be attached with a stapler or designed for lighter products are glued. Sometimes we also see that staplers are hammered on the glued boxes, and this is an indication of the high quality of the box. The gluing equipment is first adjusted along the width of the box and the glue is automatically poured into the box. Glue is sent with heat so that the glue dries quickly.

| Semi-automatic gluing equipment for corrugated boxes | |

| Produced | China |

| Voltage | 380v50hz |

| Power consumption | 4 kw/h |

| Working width | 2600*1400mm |

| Speed of operation | 0-50 min |

| Size | 5500*1800;2000 |

| Weight | 1500 kg |

| Box thickness | For corrugated boxes with 2,3,5,7 layers |

| Automatic counting function | There is |

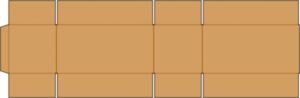

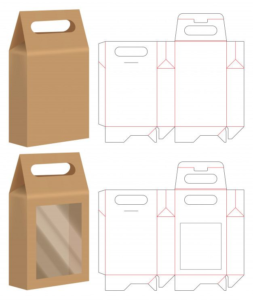

SEMI-AUTOMATIC CUTTING AND BENDING PRINTING EQUIPMENT FOR BOXES

Some boxes cannot be cut using a printer. Special cutting equipment is available for such non-standard boxes. The equipment is popularly called a crucible press. You can earn a good profit by using this equipment separately. Because it is precisely this equipment that cuts single-layered sweets and disposable containers. We present to you the variety of equipment in standard sizes. There are larger and smaller types. The equipment requires a separate mold for each shape. Our staff will tell you how to make molds and where to order them. The equipment can be moved automatically and with the help of a pedal.

| Marking equipment for semi-automatic cutting and bending for boxes ML-750 | |

| Produced | China |

| Voltage | 380v50hz |

| Power consumption | 2,2 kw/h |

| Working width | 750*520 mm |

| Speed of operation | 0-30 min |

| Size | 1500*1400*1300mm |

| Weight | 2200 kg |

| Box thickness | For corrugated boxes with 2,3,5,7 layers |

| Automatic counting function | There is |

We believe that with the help of equipment, your business will expand and your income will increase. Most importantly, we are proud to have contributed to the completion of this field with modern equipment.

Based on 0 reviews

Show reviews in all languages (1)

There are no reviews yet.