Compact toilet paper production line

Out of stock

We have seen the height of interest of most entrepreneurs in the toilet paper production business in the appeals to us now. Taking this into account, we would like to recommend a production line that takes up relatively little space, the production volume of which is sufficient for small entrepreneurs. The production line consists of the following stages:

14,900$

Out of stock

PACKAGING EQUIPMENT FROM LARGE PACKAGING TO SMALL PACKAGING

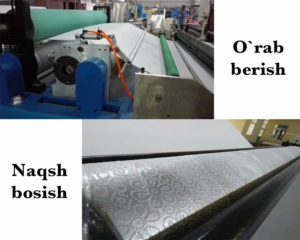

First of all, before starting work, you need to plan how many layers of toilet paper to produce. Currently, we see that manufacturers in our country are making 1, 2, and in some cases 3-story. The most common is certainly 2-story. You can make 1, 2, 3 layers in our equipment. A patterned shaft is also added to this equipment, because the patterned shaft makes your product more marketable.

| The equipment for wrapping from a large package to a small package | |

| Raw material | Secondary paper or cellulose roll |

| Packaging product | Toilet paper or roll napkin |

| Paper thickness | 13-30g/m2 |

| Roll paper width | 787-900mm |

| Embossing cylinder width | 1100 mm |

| Production capacity | 0.8-1T/day |

| Number of floors | 1; 2; 3 |

| Speed of operation | 30-40m/min |

| Change speed | There is |

| Voltage | 380v50hz |

| Power consumption | 4.5kw/h |

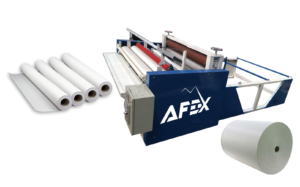

EQUIPMENT FOR CUTTING SMALL PACKAGING

This saw serves to cut the small rolls created by the above equipment into a special small size. If you want to make toilet paper, you need to cut it 10-12 cm long, and if you want to make paper towels, you need to cut it longer. This equipment can be used for toilet paper with and without an inner liner.

| Small package cutting equipment | |

| Cutting length(mm) | Changeable |

| Working capacity (tons/day) | 01.май |

| Cutting length(mm) | 3750 |

| Diameter(mm) | 1300*70*1800 |

| Weight (kg) | 560 |

| With and without bushing | Designed for both |

| Power consumption(kw) | 1,1 |

SPECIAL IRONING EQUIPMENT FOR GRAIN PACKAGING

With the help of this equipment, we can pack one or two pieces of toilet paper, which have not yet been made and will be needed by people. After all, demand should be taken into account when doing every job. Granular packaged product can come in handy when traveling to the mountains or other places. Also, through this equipment, you will have the opportunity to use other products (napkins, envelopes) for packaging.

PACKAGING EQUIPMENT

And the last stage, as always, is the block packaging equipment for convenient delivery of the product to the customer. Depending on the requirements of the buyer in the area where you live and plan to sell your product, you can pack up to 2, 4, 6, 8. When you order a packing bag, don’t forget to leave holes in it that are easy to grab by hand. This will provide additional convenience for the buyer who receives your product. The package is ready-made and closed on three sides. Then, after putting the product in it by hand, the upper part is well closed with the help of the following equipment.

| Block packing equipment | |

| Voltage | 220v50hz |

| Number of packages | 2, 4, 6, 8 |

| Material | Metal and textalite |

| Welding width | 50 cm |

| Mechanism of action | Using the foot pedal |

| Production capacity | 15-18 pieces/min |

| Manpower required | 1 person |

| Power consumption | 0.5kw/h |

There are no reviews yet.