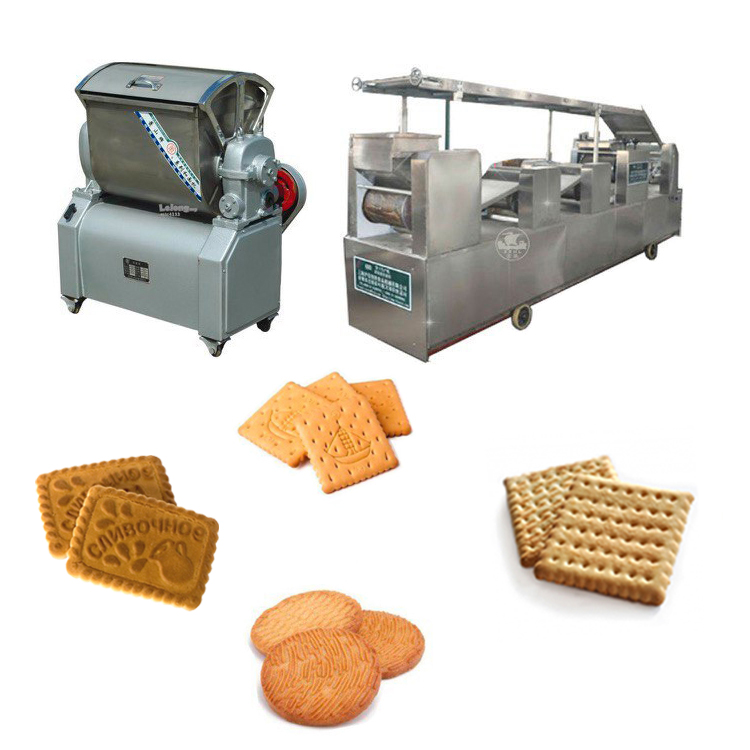

Compact biscuit production line

Out of stock

As we live with high-level technologies, our demand for them is increasing day by day. It would not be wrong to say that modern technologies have entered almost all areas of our life. One such industry is, of course, the food industry.

The equipment that we want to present to you today is also used for the production of biscuits, a product that is loved not only by the Uzbek people, but also by the whole world. This set of equipment is intended for the production of cookies. You can see such cookies in the pictures above.

AFEX-GOUP offers you a set of equipment for the production of this type of cookies. We hope that the cookies you made will be loved by our people and you will be able to collect your valuable customers in a short period of time.

37,000$

Out of stock

A variety of biscuits such as soft and hard sandwiches can be made through the biscuit production line. The automatic production line includes mixer, cookie forming equipment, tunnel molds, oil spray equipment, cooling conveyor, control box, packing equipment. Biscuits can be made according to your preferences, for example, the shape, the shape of the decoration and the thickness of the biscuit, etc.

Equipment for making dough for cookies using a mixer

| Flour mixer | |

| Produced | China |

| Voltage | 380v50xz |

| Opportunity | 250 kg/hour |

| Weight | 210 kg |

| Power | 1.5kw |

| Material | Stainless metal |

| The size | 880*630*1050 mm |

| Time to mix the flour | 3-10 minutes |

The machine is a kind of mixer suitable for all kinds of food production. The quality of the dough mixed with it is very good. The dough mixer has the quality standard SB / T 10127-92, which is the required quality standard of the food industry. A new type of decelerator used in the mixer automates the process and makes it easier.

Equipment for forming soft and hard cookies

| Equipment for forming soft and hard cookies | |

| Produced | China |

| Voltage | 380v50xz |

| Opportunity | 250 kg/hour |

| Weight | 1600 kg |

| Power | 1.5kw |

| The size | 3900*800*1450 mm |

The purpose of this equipment is to prepare soft and hard cookies, sweet cookies and other types of thick cookies.

Biscuits of various shapes can be produced by changing the molds of the equipment.

This equipment has three measuring tools for rolling out the dough. Three processes take place in the equipment: it spreads the dough, molds hard cookies, and returns the excess dough. A total of five belts are used in the equipment.

The bottom of the machine has four rubber wheels, easy to move in production and maintenance.

Tunnel oven (electric type)

| Tunnel oven (electric type) | |

| Produced | China |

| Voltage | 380v50xz |

| Opportunity | 60-70 kg/hour |

| Weight | 1800 kg |

| Power | 31.5kw |

| The size | 9000*730*1100 mm |

This tunnel consists of furnace tunnel, conveyor, conveyor control system, chimney, electric heating pipes and control cabinet. Frequency inverters keep the temperature constant at a certain size. It is possible to adjust the temperature, which not only saves energy, but also makes cookies of high quality and taste.

Equipment for spraying oil on the surface of finished cookies

| oil spray equipment | |

| Produced | China |

| Voltage | 380v50xz |

| Weight | 200 kg |

| Power | 1,5kw |

| The size | 1500*700*1200 mm |

After the tunnel oven, the baked hot biscuits are immediately delivered to the oil spraying equipment, which is necessary to produce high quality biscuits and have a better taste. A centrifugal pump is used to pump the oil from the oil tanker. Powered by an engine. There are several valves in the pipe to control the volume of oil. Equipped with a temperature control device. Oil spraying width is 360°.

Cooling conveyor

| Cooling conveyor | |

| Produced | China |

| Voltage | 380v50xz |

| Weight | 180 kg |

| Power | 1,1kw |

| The size | 4000*600*700 mm |

After the end of the oil spraying stage, the cookies are cooled using this equipment. The cooling speed can be changed.

Molds for cookies

This equipment is necessary to form the thickness of the biscuit.

| Molds for cookies | |

| Produced | China |

| Material | Stainless metal |

| Weight | 200 kg |

| Power | 1,1kw |

| The size | 800*650*750 mm |

There are no reviews yet.