Aqqand production line

Out of stock

Sugar has been used in human life for a long time and has become a product of primary importance. Nowadays, sugar is used almost everywhere, and many people cannot imagine their life without this sweet product. Also, a compact, easy-to-use, cube-shaped product called aqqand in our language, which is made from sugar products, is taking a wide place on our tables and is one of the fastest-selling products in our local food markets. Aqqand production is carried out in the following stages.

42,500$

Out of stock

Oqqand ishlab chiqarish liniyasi uchun kerak bo’ladigan ishchi maydon: 70 m2

Types of energy: Electricity

Power consumption: 16 kw/h

Number of employees: at least 2 people

We will need the following set of equipment for production.

1. Crusher for grinding sugar

2. Mixer for mixing

3. Screw conveyor

4. Forming equipment

5. Infrared drying oven

6. Cooling equipment

All equipment is made of the highest quality stainless steel and fully complies with food standards. This ensures that the equipment will serve you for a long time.

The production process of Akqand begins with grinding sugar using a special crusher.

1. CRUSHER FOR CRUSHING SUGAR

| CRUSHER FOR CRUSHING SUGAR | |

| Produced | China |

| City | Henan |

| Voltage | 380V50hz |

| Electricity consumption | 4kw |

| Rotor diameter | 230mm |

| Production capacity | 100-200 kg |

| Speed | 5700 rpm |

| Weight | 250 kg |

In the second stage of production, the crushed sugars are mixed using a mixer. If you do not intend to add anything to the powdered sugar, then you do not need a mixer. The mixer is mainly needed to add coffee, dry milk, color or other additives to the liquid. The equipment is fully hygienic and made of stainless steel. Metal thickness ensures that it does not vibrate during operation.

2. MIXER FOR MIXING

| MIXER FOR MIXING | |

| Produced | China |

| City | Henan |

| Voltage | 380V50hz |

| Electricity consumption | 4kw |

| Material | Stainless metal |

| Production capacity | 300 kg |

| Size | 1350*1350*1600 mm |

| Weight | 200 kg |

After the mixing mixer, the crushed product is delivered to the special pressing equipment through a special delivery screw conveyor. The screw conveyor is also made of food-grade stainless steel, making your work much easier.

3. SCREW CONVEYOR

| SCREW CONVEYOR | |

| Produced | China |

| City | Henan |

| Voltage | 380V50hz |

| Electricity consumption | 0,75 kw |

| Material | Stainless metal |

| Screw diameter | 140 kg |

| Length | 3500 mm |

| Weight | 80 kg |

At the next stage, the most basic process of production takes place. That is, the crushed sugar powder is made into liquid form with a high-pressure press using the forming equipment. The equipment is made of SUS304 stainless steel material. The control panel of the equipment is equipped with a microcomputer PLC system. During pressing, 3% water is added to the crushed sugar. This ensures that the flow is stronger.

4. FORMING EQUIPMENT

By changing the molds, you can produce different sizes of flowers. You can also make different shapes of the flow by changing the shapes of the molds.

| Press forming equipment | |

| Produced | China |

| City | Henan |

| Voltage | 380V50hz |

| Electricity consumption | 3 kw |

| Material | Stainless metal |

| Production volume | 200 kg/h |

| The size | 1700*980*1600 mm |

| Weight | 800 kg |

MOLDS

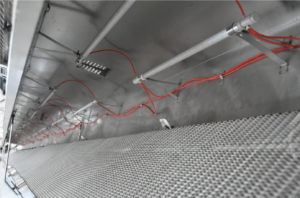

After the press equipment, the granulated sugar becomes liquid and slightly moist due to the mixing of water. At the next stage, the effluents are dried in conveyor drying equipment. The drying equipment is equipped with infrared rays, and infrared rays have a number of advantages.

- The use of infrared radiation during drying of products allows preservation of 80-90% of biologically active substances and vitamins in the product.

- Energy saving

- High efficiency and speed in drying

- Low air temperature for drying. Average air temperature is 40-60 °C

- After the product is dried in an infrared radiation oven, all its physical and chemical properties are restored.

6. INFRARED LIGHT DRYING OVEN

| INFRARED LIGHT DRYING OVEN | |

| Produced | China |

| City | Henan |

| Voltage | 380V50hz |

| Electricity consumption | 8 kw |

| Material | Stainless metal |

| Production volume | 0-10 metr/min |

| The size | 1900*700*1150mm x4 |

| Weight | 90kg x4 |

After the drying oven, the effluents are cooled in a fan cooling unit.

| Cooling equipment | |

| Produced | China |

| City | Henan |

| Voltage | 380V50hz |

| Electricity consumption | 0,25 kw |

| Material | Stainless metal |

| Production volume | 0-10 metr/min |

| The size | 1900*1000*700 mm |

| Weight | 60kg |

| Price | |

| Sugar crushing crusher | $ 2800 |

| Mixer for mixing | $1600 |

| Screw conveyor | $1800 |

| Forming equipment | $18300 |

| Infrared drying oven | $15800 |

| Cooling equipment | $2200 |

| Total: $42,500 (CIP Tashkent) | |

There are no reviews yet.