19 Liter Filtered Still Drinking Water Production Line (For Offices and Homes)

Out of stock

The demand for clean drinking water is increasing all over the world. Including in our country, the demand for clean drinking water is increasing year by year even in remote areas. The demand for water that passes through high-tech filters and is free of all bacteria is also increasing in large cities. This is because metal pipes are used in the water supply system. they form corrosion in water. In addition, the level of softness of water is softened with the help of special filters. Pay attention to the following minimum requirements for organizing production:

24,900$

Out of stock

Briefly about the project:

Water supply: Spring, artesian and other sources of drinking water

Power supply: 380v 50hz

Power consumption: 9kw/h

Working speed: 50-100 pieces/hour (19L)

Number of employees: 2 people

Metal used for equipment: SUS304

Sewerage system: Appropriate if available

Required area: a building of not less than 70 m2

It is advisable to contract with a transport or delivery service company for the delivery service.

We advise you to discuss the above requirements with the company’s staff before placing an order.

8 STAGE REVERSE OSMOSIS MEMBRANE WATER FILTER EQUIPMENT

Reverse osmosis is the application of a solution with a higher osmotic pressure to pass water through a special semi-permeable membrane and separate it from the solution. Since this process is the opposite of osmosis, it is called reverse osmosis. According to the different osmotic pressure of different materials, it can be used to achieve the purpose of separating, extracting, purifying and concentrating the solution. It can remove organic substances with low molecular weight, such as bacteria, poison, heat source, etc. A reverse osmosis device basically separates the range of ions in the solution. It does not require heating and there is no transition process, so it consumes less energy than traditional methods. A reverse osmosis device is small and easy to use, and has a wide range of applications. The reverse osmosis device is used to purify industrial water without consuming a large amount of acid and alkali, without secondary pollution, and its operating costs are relatively low. Water treated by reverse osmosis has high purity. In addition to removing only ionic range dirt, it can also remove organic contaminants, microorganisms, viruses and pyrogens that are difficult to remove by other methods.

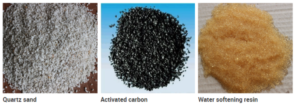

steps involved in water filtration

| Reverse osmosis water filtration equipment | |

| Produced | China |

| City | Shanghai |

| Working power | 1000l/h |

| Filtering steps | 8 levels |

| Material | Sus 304 stainless steel |

| OSMOS membrane | 4040 |

| Power consumption | 2.5kw/h |

| Water use efficiency | 50% |

| Size | 1870*650*1850 mm |

OZONE GENERATOR

| Water type | Plain water | Drinking water | Spring water |

| Ozone concentration | 0.1-0.3 mg/l | 0.2-0.4 mg/l | 0.4-0.6 mg/l |

| Ozone layer size | 1-2 grams/ton | 2-3 grams/ton | 3-5 grams/ton |

Ozone is more powerful than chlorine in oxidizing disinfection. It can not only thoroughly sterilize and disinfect, but also neutralize harmful components in water, remove heavy metal ions and other impurities such as iron, manganese, sulfide, benzene, phenol, organophosphorus, organochlorine, cyanide, etc. Germicidal efficiency is better than chlorine disinfection and UV disinfection. Unlike chlorine, residual ozone can decompose into oxygen and does not cause secondary pollution. After ozone processing, the water is colorless and odorless and tastes good. This is one of the main criteria determining the quality of drinking water.

WATER STORAGE TANKER 2T

As you know, tankers are needed to store water before and after filtration. We offer you 2 stainless steel tankers of 2T each. We can also supply larger storage tanks at additional cost upon customer request.

| WATER STORAGE TANKER 2T | |

| Produced | China |

| City | Shanghai |

| Water capacity | 2000l |

| Material thickness | 1,0 mm |

| Material | Sus 304 stainless steel |

| Location | Vertical |

in this picture we can see the arrangement sequence of 2 water storage tanks, ozone generator and water filter.

MONOBLOC WATER FILLING EQUIPMENT (washing, filling and capping)

3-in-1 water injection equipment, all processes take place without human intervention, inside the equipment protected by glass. Our equipment is made of high-quality sus304 stainless steel, and can pour 19L of water using the line. The equipment thoroughly washes the container before pouring water into the pet containers, for this there is a washing channel and fills the pet containers with water through the water pouring channel. At the last stage, he closes the pet bottles filled with water by pressing the lids. It includes washing, filling, covering three parts in one body. The design of the machine reduces the contact time of the drink with the external environment, improves sanitation and guarantees safety.

| Monoblock water filling equipment 19L | |

| (Washing, filling with water and closing the lid) | |

| Produced | China |

| Production capacity | 100-120 units/hour |

| Number of water filling heads | 1 pc |

| A place to close the lid | 1 pc |

| Dishwashing compartment | 1 pc |

| Container size | F270x490mm |

| Container size | 19L |

| Power consumption | 1.5kw/h |

| Weight | 800 kg |

| Material | SUS 304 |

| Size | 2800*800*1700 mm |

| Voltage | 380v50hz |

PET CONTAINER UNCOVER AND EXTERIOR WASHING EQUIPMENT

As you know, in the 19L water business, because the cost of the bottles is expensive, they are reused. To reuse PET bottles, the inside and outside are washed with high-pressure water and shots. This equipment is also used to separate the special cap installed on the tip. The machine automatically stops when you open the top for safe operation. All parts are made of stainless steel and will serve you for a long time. The washer is an indispensable equipment in the pre-barrel treatment process of the drinking water production line, and it is usually operated by an air compressor. Our company introduces and adopts the advanced technology of cleaning PET bottles.

| Separating the pet container from the lid and washing equipment with a shot | |

| Produced | China |

| Washing power | 100-120 units/hour |

| Cover separation part | 1 pc |

| Shot cleaning unit | 1 pc |

| Cleaning the inside of the tank with high pressure water | 1 pc |

| Container size | F270x490mm |

| Container size | 19L |

| Power consumption | 1.1kw/h |

| Weight | 120 kg |

| Material | SUS 304 |

| Size | 1100*750*1150 mm |

| Voltage | 380v50hz |

Once the equipment is ready, you can sell your products from sales outlets and with delivery service. This business is a profitable business, you can sell additional coolers and pneumatic pumps for water to customers along with water.

There are no reviews yet.