2-layer PVC plastic roofing (tile) production line.

Out of stock

148,900$

Out of stock

1-Project Overview

Raw Materials: PVC powder, CaCO3, CPE, PE-WAX, Stearic acid, Complex stabilizer, ACR, kerosene, ASA material.

Final Product Description:

- Width: 1040 mm

- Thickness: Typically 2.0-3.5 mm

Production Capacity: 300-350 kg/hour

Central Height: 1000-1050 mm

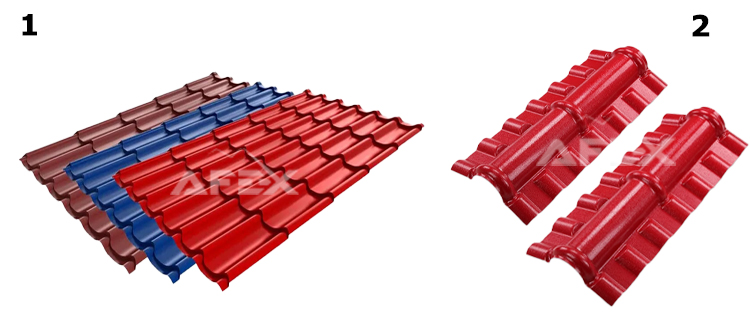

2-Final product image

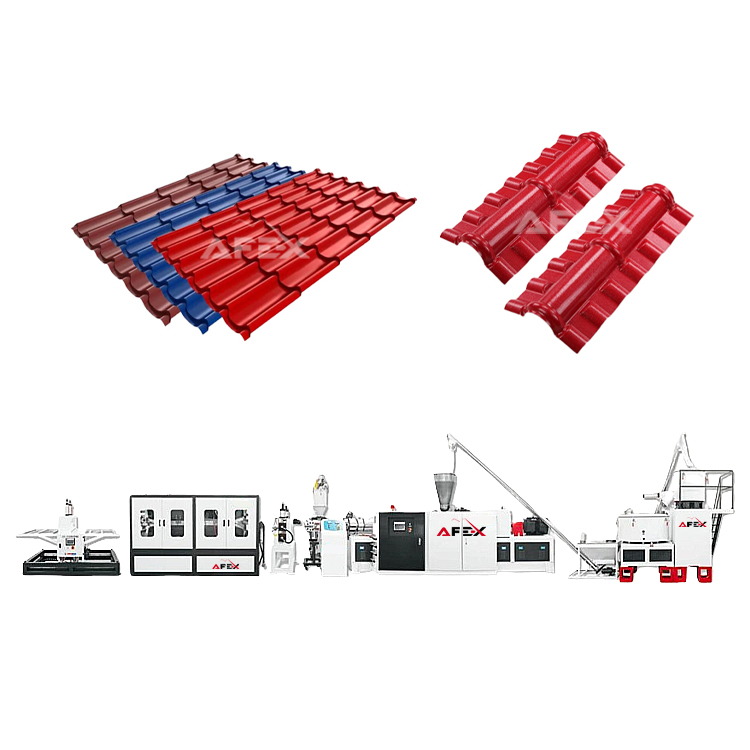

- Plastic PVC+ASA roofing panel

- Roof Trim Accessory

3-Description of operating conditions (provided by the customer)

| Склад / мастерская | Line Size: 25m (Length) × 3.5m (Width) × 3.5m (Height).

Foundation Construction, Construction Works, Earthworks, and Wall Works. Provision of Cranes, Loaders, or Other Lifting Equipment; Materials and Tools for Installation.

|

| Temperature / Humidity | 0-35°C/≤95% |

| Power Supply | 3-phase, 380V, 50 Hz** |

| Wire/Cable/Water Hose | Electric Supply: Wiring/Cables from the power supply to the control cabinet of the production line.

All electrical cables from the control cabinet to each machine. Water Hose: Water supply to machines and pools.

|

| Cooling Water | Without dissolved or suspended minerals** such as phosphorus, sulfur, iron, and others.

Inlet temperature T1: max. 15°C. Outlet temperature T2: T2 = T1 + 5°C Hardness: 5-8 °dH (degrees of hardness). Reverse flow: pressureless. |

| Kopmressor | 7.5KW (0.6-0.8Mpa) |

4-Energy Consumption

Transformer: Over 250 kW

Cooling Water: ≤20°C, ≥0.3Mpa, 5-6 tons/hour

Compressed Air: 0.3m³/min, >0.6Mpa

Number of Employees: 3-5 people per shift (24 hours, 2 shifts required)

5-Equipment in the Line

Screw Loader

SJZ 80/156 Twin-Screw Extruder (Conical)

Mold Section

Pattern Printing Roller

Temperature Control Controller

Shaping Equipmenti

PLC-Controlled Cutting Equipment

Assembly Table

Chain Conveyor Furnace

Accessory Shaping Equipment for Roof Edge Sealing

Molds for Roof Edge Sealing Accessories

Screw Loader (for Mixer)

Special Mixer

6-Equipment Technical Specifications

Screw Loader

| Nominal feeding capacity | 500 kg/hour |

| Voltage | 380V |

| Motor power | 2.2 KW |

| Pipe diameter | φ 102mm |

| Material | SUS 304 (Stainless Steel) |

SJZ 80/156 Conical Twin-Screw Extruder

| Screw (Shnek) |

Features: The screw is made of 38CrMoAlA alloy, tempered, nitrided, with a surface coating for high hardness and wear resistance, achieving a hardness of HV950 or higher. The screw handle is designed to evenly distribute the working moment with two symmetrical keys, ensuring uniform and reliable operation. |

| Barrel |

Features: The barrel is made from a composite alloy material, hardened, carburized, and has a hardness of up to HV950. The inner surface is hard-chromed and polished for smooth operation. |

| Drive System |

Bearings: All bearings in the gearbox are from internationally renowned brands, providing long service life, high load capacity, and surface hardness. |

| Feeding System |

| Motor Power: 3 KW |

| Feeding System |

|

| Electrical System |

|

Mold Section

Mold Type: Single Charge

Material: Made from 5CrNiMo steel, heat-treated with surface polishing. Both the internal and external surfaces are electroplated, with the mold head surface chrome plating thickness between 0.04-0.05 mm.

Heating Method: Heating is done using a closed-type heating system with a heating sterjn.

Effective Width: 1300 mm

Adjustment Range: 1-4 mm

Heating Zones: 7 zones

Heating Power: 3.5 kW per zone

Pattern Printing Roller

- Working Speed: 1-5 meters per minute.

- Control Motors: 1.5 kW x 2 sets.

- Roller (Valve) Dimensions: φ295mm × 1300mm.

The system uses two types of rollers:

- Upper Roller: Raised pattern roller.

- Lower Roller: Reverse roller.

Both rollers are treated with hard chrome plating on the surface (depth: 0.10-0.15mm) to ensure durability and precision in pattern transfer.

Control System: The system operates with an ABB inverter. Spiral runners are used in the roller, ensuring uniform surface temperature for consistent pattern quality.

The synchronization of the upper and lower cylinders is guaranteed by two separate motors, ensuring that both rollers work together seamlessly. This setup guarantees high-quality pattern printing on the material.

Temperature Control Controller (for rollers)

| Type | Oil-heated |

| High-temperature pump | 0.75 kW x 2 |

| Electric heater power | ≥ 9 kW x 2 |

| Electromagnetic valve | High-quality branded valve |

Shaping Equipment

The shaping machine features a protective shell, ensuring safety and an aesthetically pleasing design. The aluminum shaping module is made of high-quality aluminum alloy, treated at a machining center for durability, with multi-functional capabilities and strong interchangeability. The driver module, made of 40Gr material, undergoes quenching and blackening processes for enhanced strength and hardness. The transmission system uses a turbine reducer with synchronized movement of both sides of the module for smooth operation. The entire line is driven by a motor, with forward and backward motion. An air cooling system within the stamp set ensures efficient cooling of the module’s rear section. The distance between the upper and lower modules can be manually adjusted to ensure the shape’s integrity. |

|

|

PLC-Controlled Cutting Equipment and Assembly Table

Cutting Type: The cutting equipment utilizes a circular saw type, with a motor power of 2.2 kW. It is designed with a special adjustable locator for precise placement, ensuring the accuracy of each cutting position. The machine’s center of gravity is low, contributing to more stable operation during cutting. It is equipped with a dust collection system to minimize airborne particles during the cutting process.

The cutting system uses a microcomputer-based electrical control, allowing for high-precision operation and minimizing errors, ensuring reliability in production.

Assembly Table:

- Material: Stainless steel

- Length: 3000 mm

This assembly table offers a sturdy, durable platform for assembling cut parts, optimized for efficient workflow and providing flexibility for various post-processing tasks.

Chain Conveyor Oven

| Oven Length | 3500 mm |

| Oven Width | 1700 mm |

| Heating Power | 26 KW |

| Conveyor Power | 0.75 KW |

| Production Capacity | 500 units / within 8 hours |

The Roof Edge Sealing Accessory Shaping Equipment

| Control | Cylinder control for both top and bottom |

| Mold material | Alloy aluminum |

| Molds | For 4 types of tiles |

This equipment is semi-automatic and can produce various shaped products from PVC sheets.

Molds for roof closure accessories.

- Roof closure accessory

- Two-side connection angle accessory

- Three-side connection angle accessory

- Bottom side accessory for roof

Screw Conveyor (for mixer)

| Nominal transfer capacity | 500kg/hour |

| Voltage | 380V |

| Motor power | 2.2 KW |

| Pipe diameter | φ 102mm |

| Material | SUS 304 |

Special Mixer

| Hot Mixer | |

| Total Volume | 500 L |

| Usable Volume | 330 L |

| Mixing Time | 8-10 minutes |

| Production Volume | 500-750 L |

| Cold Mixer | |

| Total Volume | 1000 L |

| Usable Volume | 500 L |

| Mixing Time | 8-10 dminutes |

| Production Volume | 500-750 L |

| Cooling Type | Cold water cooling |

| Electrical Components | |

| Hot Mixer Motor | 75 KW |

| Cold Mixer Motor | 15 KW |

There are no reviews yet.