Corner profile (perfougol) Production equipment

Out of stock

Home renovation is a pursuit of beauty and well-being. If the walls are uneven or there are small errors along the surface, this is not scary. The most important thing is the flatness of the corner edges, because the corner edges are the part that quickly attracts a person’s attention. How to achieve a smooth edged surface?

19,800$

Out of stock

Few people know that the secret of the visual beauty of the walls lies in the correct and precisely edged profiles. This concept refers to the following areas of application of sand plasters:

external and internal angles;

connecting walls on ceilings and floors;

protruding parts of any structures (belts, boxes, other structures).

All these areas (edges) must fit the intended design. It should be straight and solid. Former plasterers achieved the acceptable quality almost by hand. But modern accessories simplify and speed up the process. Therefore, the demand for these accessories is increasing day by day.

In fact, all of them are widely used corner profiles with holes for sand plaster or plaster. They are used almost everywhere where gypsum mixtures are used with corners. Corner profiles with flat holes are available for internal corners and external corners. It can be of different widths, as well as aluminum, metal or plastic (made of polyvinyl chloride). In general, there is no difference in function. You cannot say that some are better or worse. But the galvanized metal corner is tougher than others and resistant to deformation under external influence. Therefore, it is convenient to use it with gypsum or sand plaster.

Today we will tell you about the equipment for the production of metal corner profiles.

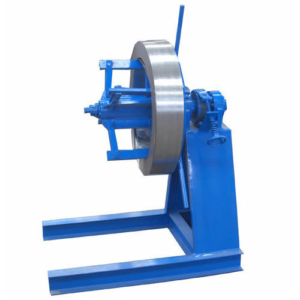

TIN ROLL CONVEYING EQUIPMENT

| Tin roll transfer equipment | |

| Workable material | Black metal tin and galvanized tin |

| Tin width | 50-100 mm, other sizes may be available according to the customer’s request |

| Tin thickness | 0.3-1.5mm |

| Transmission speed | It varies depending on the mechanical tension |

| Dimensions | 500*650*1000 mm |

| Weight | Around 110kg |

VARIABLE SPEED TRANSMISSION DEVICE

| Variable speed transmission device | |

| Workable material | Black metal tin and galvanized tin |

| Tin width | 50-60 mm, there can be other sizes according to the customer’s request |

| Tin thickness | 0.3-1.5mm |

| Transmission speed | 0-20m/s |

| Dimensions | 500*750*1000mm |

| Weight | Around 100 |

| Power consumption | 0.5 kw/h |

| Voltage | 380V50Hz 3 phase |

| Control Panel | Button control |

STAMPING EQUIPMENT FOR HOLES

| Press stamping equipment | |

| Workable material | Black Metal tin and galvanized tin |

| Tin width | 50-60 mm, there can be other sizes according to the customer’s request |

| Tin thickness | 0.3-0.6mm |

| Tons of clicks | 40T |

| Dimensions | 1100*750*2050mm |

| Weight | Around 1.5t |

| Power consumption | 3 kw/h |

| Voltage | 380V 50Hz 3 phase |

| Control Panel | Button control |

| Production speed | 40-45m/min |

| Mold material | Cr12 |

EQUIPMENT FOR MANUFACTURING V-SHAPED CORNER PROFILE

|

|||||||||||||||||||||||||||

Based on 0 reviews

Be the first to review “Corner profile (perfougol) Production equipment” Cancel reply

Related products

-

Metalworking equipment, Solution product lines

Metal pipe and profile production line

0 out of 5(0)We will continue to provide detailed information on profitable businesses and technologies for customers of AFEX GROUP! Stay tuned!

Shaped pipes and profiles are considered one of the widely used products today in many fields – automotive industry, construction, metallurgy, gas pipelines, greenhouses, tables and chairs, doors, light constructions and other fields. The business of production of shaped pipes has become a very promising business direction today. Of course, the buyers of products are not only large enterprises, iron markets and individuals, but also successful buyers. Of course, not every region has factories or workshops that produce such products, so why not still take advantage of the space and start your own manufacturing enterprise?

SKU: n/a198,700$ -

Metalworking equipment, Other equipment

Leather belt production line

0 out of 5(0)Most of the leather belts are imported products. That is why we believe that the production of this product in the territory of our country will give you good results. We first need raw leather or a leather substitute to make the product. 10 types of equipment are involved in the production process, and our company recommends these equipments to you at the most reasonable prices.

SKU: n/a25,700$ -

Metalworking equipment

AF-M7 Metal pipe engraving machine

0 out of 5(0)Metal pipe embossing equipment is used for making beautiful embossing on any metal pipe. The equipment has simple operation, high production efficiency, stable forming effect and other features.

Pipe materials: stainless steel/copper/carbon steel/iron/galvanized/aluminum etc.

Pipe shape: Round and other shapes.

Application: Pipes designed for furniture, construction and other industries.

SKU: n/a11,800$

There are no reviews yet.