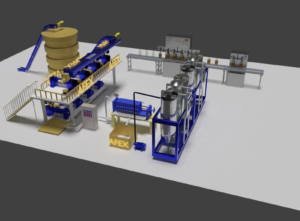

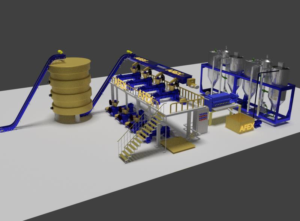

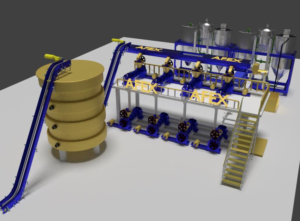

vegetable oil production line (6-8T raw material per day) AF-L026

1 in stock

Encouraged by the positive changes taking place in our country, the AFEX-GROUP company recommends the next compact vegetable oil production line from cotton seeds to you entrepreneurs. Until now, the production of cottonseed oil belonged to JSC “Uzpakhtayog”, and private entrepreneurs were not allowed to produce cottonseed oil. According to the President’s decision on January 17, 2018, now 27 highly liquid products are sold by monopolistic enterprises based on market principles only through stock trading. Among these products, the presence of seed products is also pleasing. Today, we will try to provide you with information about the cottonseed oil production line, which is one of the most popular products in our country. In our line that we recommend to you below, you will be able to produce edible cottonseed oil.

We can also add Extraction and Deporafining parts at extra cost according to customers request. Through this recommended line, you can also use other types of raw materials, including: sunflower pistachios, almonds. you will be able to get good quality oil from sesame etc.

84,900$

1 in stock

Work area required for the project: 150 m2

Recommended storage area: 200 m2 and larger

Types of energy: Water and electricity

Total power consumption: 92kw/h

Number of employees: 4 people

Sewage system: required

Let’s first introduce you to the series of equipment:

A conveyor with a special screw that lifts the seed to the press

Seed roasting equipment

Special press for extracting oil from seeds (model 110)

Vertical pressure filtration equipment

Refining equipment including steam equipment (up to 2.5T per day in complete condition)

Oil UF sterilization equipment

Special stainless pumps for oil transportation 3 pcs

Equipment for inflating PET bottles for the product

A mini-computer laboratory for determining the quality of oil

Deparaffinization (vimorozka) equipment

PET bottle filling equipment

PET container capping equipment

Semi-automatic adhesive labeling equipment for PET containers

Paragenerator for the refining process

Air compressor 2 pcs

Now we will introduce the above equipment in detail for you.

A conveyor with a special screw that lifts the seed to the press

This equipment serves to release the seed into a special press. To prevent the equipment from clogging during operation, a special vibrator is installed on it, and it can also be used for powder products.

| A conveyor with a special screw that lifts the seed to the press | |

| Produced | China |

| Voltage | 220V50hz |

| Power consumption | 1.1kw |

| Material | SS208 stainless steel |

| Pipe diameter | 110mm |

| Weight | 190 kg |

| Lifting height | 2.5 m |

Seed roasting equipment

| Production volume | 300 kg/h |

| Power | 1.5 Kv |

| Electric heating | 30*1300w |

| Weight | 410 kg |

| Size | 2420*1200*1300 mm |

Special press for extracting oil from seeds (model 110)

With our cold press oil press, you will be able to get 90-94% oil from the seed. The equipment is made of durable metal CR13, which will serve for a long time during operation. Using this press, oil can be extracted from sesame, sunflower pistachios, peanuts, almonds and other products.

| Special press for extracting oil from seeds (model 110) | |

| Produced by | China |

| Voltage | 380v50hz |

| Power consumption | 15kw |

| Material | Carbon metal and SS208 stainless metal |

| Model | 110 |

| Weight | 680 kg |

| Production volume | 250-300kg/hour |

Vertical pressure filtration equipment

The inner part of the vertical high pressure filtration equipment consists of multi-stage filters, which is the oil filter used in the industry. With this filter, you get a high-quality product and high performance. The equipment is made of strong metal and the inner part is resistant to high pressure. Also, it is easy to replace the filters inside the equipment. The product meets the requirements in terms of quality and hygiene, because everything is done in a closed state without the human factor.

| Vertical pressure filtration equipment | |

| Produced | China |

| Voltage | 380v50hz |

| Power consumption | 3kw |

| Material | Carbon metal |

| Model | CPF-10 |

| Weight | 320kg |

| Production volume | 300-400L/hour |

| Operating temperature | 0-150С |

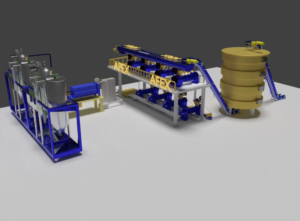

Refining equipment with steam generator (500L at a time)

Refining and deodorizing processes are one of the main processes that determine the quality of this oil. below we will briefly explain to you what parts the equipment is made of and its function.

Refining tank – for oil degumming using hot water

Deoxidation tank – for neutralization using alkali

Bleaching tank – sand cleaning and bleaching

Vibrating filter- retains sediment products in the oil

Deodorizing Tanker- Eliminates unpleasant odors in oil

Steam generator – to heat the tank for the deodorization process

Filter – for final filtration before consumption

Catcher – to catch harmful substances

Tanker for hot water and alkali

Tanker for bleaching raw materials and residual product

To transfer from the pump-filter to the bleaching tank

Vacuum pump- To create a vacuum condition in the tanker

Control Panel

| Refining equipment with steam generator (500L at one time) | |

| Produced | China |

| Voltage | 380v50hz |

| Power consumption | 59,55kw |

| Material SS stainless metal | SS stainless metal |

| Model HLX-500L | HLX-500L |

| Its weight is 2320 kg | 2320 kg |

| Production volume 500L/time (8-10 hours) | 500L/once (8-10 hours) |

| Operating temperature 0-150C | 0-150C |

| Size | 5200mm*1300*1450mm |

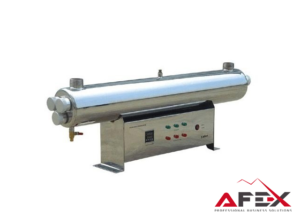

Oil UF sterilization equipment

It is desirable to sterilize the oil before packaging. Prior to packaging in a chilled state, the sterilized part is directed to the packaging equipment.

| Oil UF sterilization equipment | |

| Produced | China |

| Voltage | 220v50hz |

| Power consumption | 500w/h |

| Material | 304 SS stainless metal |

| Weight | 30 kg |

| Production volume | 500L/hour |

| Operating temperature | 5-60C |

AIR COMPRESSOR

An air compressor is required for high pressure air necessary parts for the smooth operation of the equipment.

| Air compressor | |

| Produced | China |

| Voltage | 380v50hz |

| Power consumption | 4kw/h |

| Material | Carbonmetall |

| Weight | 140 kg |

| Air output volume | 826L/min |

| Operating temperature | 5-60C |

| Size | 159*59*98cm |

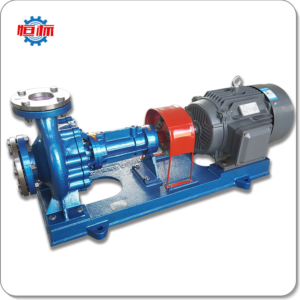

SPECIAL CENTRIFUGAL PUMP FOR OIL

We need special stainless pumps to transport oil through pipelines.

| SPECIAL CENTRIFUGAL PUMP FOR OIL | |

| Produced | China |

| Voltage | 380v50hz |

| Power consumption | 2kw/h |

| Material | Carbon metal and stainless metal |

| Weight | 70 kg |

| Oil output volume | 1-800m3 |

| Operating temperature | 20-320C |

| Size | 159*59*98cm |

| Lifting height | 10-130 m |

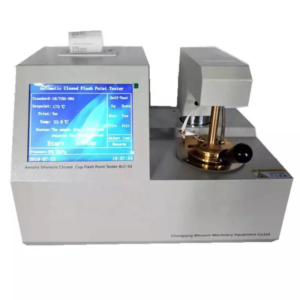

MINI LABORATORY EQUIPMENT FOR OIL

It is required to undergo quality control before packing the product every day. In this case, the probability of our entrepreneurs producing high-quality products is high.

| Mini laboratory equipment for oil | |

| Produced | China |

| Voltage | 380v50hz |

| Power consumption | 0.2kw/h |

| Material | ABS plastic |

| Weight | 12 kg |

| Detection speed | Max 2.4 kg/min |

| Operating temperature | 20-320C |

| Size | 320*240*180mm |

| Indicators | 10 1mg water, ±0.2%; 1mg water, <±0.3% |

Deparaffinization (vimorozka) equipment

| Production volume | 1000 kg/24 hours |

| Power | 3.75 sq |

| Internal volume | 500L |

| Vessel diameter | 800mm |

| Material | SS 304 |

| Voltage | 380V 50Hz |

| Theft | 1250 kg |

| Size | 5000*1200*2550mm |

EQUIPMENT FOR MANUFACTURING PET CONTAINERS FOR OIL PACKAGING

PET bottles remain the main packaging product for cottonseed oil and sunflower oil. To produce PET bottles, you need a PET capsule, which can be found in different regions of our country.

| Equipment for the production of pet dishes | |

| Produced | China |

| Voltage | 380v50hz |

| Power consumption | 14kw/h |

| Material | Carbon metal |

| Weight | 1100 kg |

| PET container size | Max 2 L MIN 0.33L |

| Speed of operation | 800-1000 units/hour |

| Size | 1630*620*1590mm/750kg |

| Capsule heating equipment | 1780*570*1380mm/350kg |

| Additional parts | Air compressor, 1 mold, air filter |

OIL TANK FILLING AND COVERING EQUIPMENT

When the baklashki are ready, they are filled with oil, the lid is closed and they are made into a finished product. The equipment can pour into bottles from 1l to 5l.

| Equipment for filling and capping oil containers | |

| Produced | China |

| Voltage | 220v50hz |

| Power consumption | 500kw/h |

| Material | SS304 stainless steel |

| Weight | 280 kg |

| Pour size | 1L-5L |

| Speed of operation | 100-300 pieces/hour |

| Size | 600*598*1300mm |

| Capsule heating equipment | 1780*570*1380mm |

| Additional parts | Air compressor |

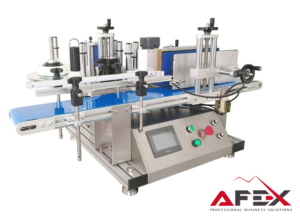

PET CONTAINER LABELING EQUIPMENT

This equipment, which is one of the integral parts of the packaging process, attaches the adhesive label to the product itself. The equipment can label bottles from 500ml to 1.5l.

| Labeling equipment for PET bottles | |

| Produced | China |

| Voltage | 220v50hz |

| Power consumption | 1500w/h |

| Material | SS304 stainless steel |

| Weight | 120 kg |

| Diameter | 30-120mm |

| Speed of operation | 20-200 units/hour |

| Size | 600*598*1300mm |

| Height | 15-200mm |

Based on 0 reviews

Show reviews in all languages (2)

There are no reviews yet.