Food equipment

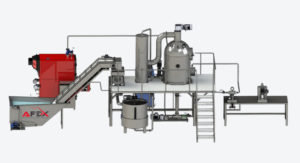

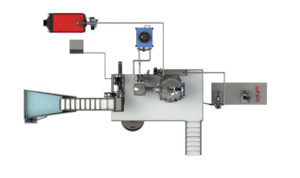

Tomato paste production line

The tomato processing line is easy and convenient to use, greatly reducing the labor force, and you can produce products with low power in small areas. This line has a processing capacity of 250 kg of tomatoes per hour. With a condensate system, it thickens the product well while retaining its flavor, allowing the consumer to use it for a longer period of time.

83,700$

| Producing state | Turkey |

| Production volume | 250kg / H |

| Product size that goes for 1kg dark paste | 4-5kg tomato |

| Raw materials used | Tomatoes, hard wheat, water salt, olive oil or vegetable oil,spices and herbs,acidic substances |

| Required space for equipment | 110-120m2 |

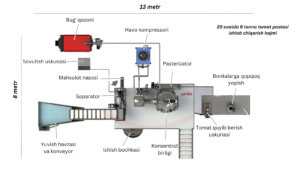

| Size | 13m*8m*4.5 m |

| Used material | Stainless metal |

| Total capacity | 17.44 kW |

| Type of management | Automatic 17 kWh |

| Total power consumption | 17 kWh |

| The total water consumption was. | 5-12tonna/H |

| Total steam consumption | 150kg / H |

| Suvta’minoti | Necessary |

| Gas supply | Necessary |

| Sewer system | Necessary |

| Manpower | 3rd-4th |

Advantages of tomato paste production business

- Bulk supply: paste is the most common and bulk product in our life, and there is a bulk supply for Paste products in general. This can provide your business with a reliable customer base.

- Product expansion: you have the opportunity to expand your line of products even later because in addition to the tomato paste used in food, it is also possible to produce different sauces for restaurants. This flexibility allows you to serve different customer preferences and market segments.

- Long shelf life: the Paste has a long shelf life, suitable for storage and distribution in warehouses. This can help reduce the effects of rapid decay.

Tomato paste preparation process

- Fully made of stainless steel and easy to clean.

- Tomatoes are poured into the conveyor pool, and here they pass through the conveyor to the tomato grinder.

- Tomatoes are first chopped, then separated from the peel. Then, tomato juice is taken into a heating container.

- By heating at 75 ° C, the arched tomatoes are turned into juice.

- At 55-60 ° C on a vacuum equipment, boiled tomato juice is poured.

- Boiling tomatoes takes about 6-8 hours. Then tomato paste is poured into a barrel with a pump for cooking.

- With the tomato pouring equipment on the right side of the line, the equipment of the required size is filled.

- The heater container contains a mixer and this prevents the product from sticking to the container.

- At the bottom of the cooking pot, you can observe a constant level with a high heat-resistant mirror.

- Nylon binding equipment is included in the steam boiler.

- The steam boiler works with coal and natural gas, and the choice of this is optional.

Detailed classification of line parts

Wash basin

- 240 liter water volume

- open-wing Rotary Pump

- 0.75 kw engine

Separator

- Engine with a power of 7.5 kW 1400 pm

- 500 kg/h tomato processing power

- 0.7 m sieve surface

- 1.5 mm hole diameter

- Garbage shnegi

Heating barrel

- Volume of 450 liters

- Steam heating

- Mixer includes

Concentrate unit

- 850 liter volume boiling unit (working Volume: 500 kg, final product volume 200-350 kg)

- Steam heating

- 0.75 kW 125-250 water pump

- 3 kW vacuum pump

- 1.1 kW mixer

- Lighting part

- Glass washing machine

- Sampling panel

Pasteurizer

- Scraper blades designed for high-grade Adhesion Products

- Steam heating

- Automatic temperature control system

- Sealing: mechanical seal

- 0.55 kw engine

Product pump

- Monopomp with a capacity of 2 tons/hour, suitable for food

- 2.2 kW engine

- Stainless cap butterfly valve

Tomato pouring equipment

- Volume 100-900 G

- Weight control using sensors

- Pneumatic drive

Closing the lid on the jars

- Power 0.09 kW

- Pneumatic control

Air compressor

- 1.5 kw

- 8-part

Steam boiler

- 200 kg/h steam generating capacity

- Gas or diesel powered

- 6 meter pipe

- 50 liter hot water boiler

Cooling equipment

- With a capacity of 10,000 kcal

- Made of galvanized material

- All other parts except the cooling device and steam boiler are made of 304 stainless material

- Total electricity consumption is 17 kWh

- Total water consumption 5-12 t / h

- Total steam consumption 150 kg / h

There are no reviews yet.