Filtered still mineral water production line AF-L32

Out of stock

As our lifestyle improves, we begin to pay serious attention to the quality of our daily consumer goods. Especially drinking water is the most necessary and important blessing for human life. From time immemorial, our forefathers strictly controlled spring water, and as time progressed, pineapples were further processed with the help of modern filters and delivered to the people while preserving their minerals. Water production business has been booming recently due to high demand. Of course, we developed the offer taking into account the high demand for non-carbonated water by a large segment of the population. Therefore, the AFEX-GROUP company brings to your attention the production line of still mineral water.

65,800$

Out of stock

Briefly about the project:

Water supply: Spring, artesian and other sources of drinking water

Power supply: 380v 50hz

Power consumption: 13kw/h

Production speed: 1500 pieces/hour (500ml)

Number of employees: 4 people

Metal used for equipment: SUS304

Sewerage system: Appropriate if available

Required area: Building not less than 100 m2

We advise you to discuss the above requirements with the company’s staff before placing an order.

8 STAGE REVERSE OSMOSIS WATER FILTER EQUIPMENT

Reverse osmosis is the application of a solution with a higher osmotic pressure to pass water through a special semi-permeable membrane and separate it from the solution. Since this process is the opposite of osmosis, it is called reverse osmosis. According to the different osmotic pressure of different materials, it can be used to achieve the purpose of separating, extracting, purifying and concentrating the solution. It can remove organic substances with low molecular weight, such as bacteria, poison, heat source, etc. A reverse osmosis device basically separates the range of ions in the solution. It does not require heating and there is no transition process, so it consumes less energy than traditional methods. A reverse osmosis device is small and easy to use, and has a wide range of applications. The reverse osmosis device is used to purify industrial water without consuming a large amount of acid and alkali, without secondary pollution, and its operating costs are relatively low. Water treated by reverse osmosis has high purity. In addition to removing only ionic range dirt, it can also remove organic contaminants, microorganisms, viruses and pyrogens that are difficult to remove by other methods.

| Produced | China |

| City | Shanghai |

| Working power | 1000L/hour |

| Filtering steps | 8 steps |

| Material | SUS 304 stainless steel |

| OSMOS membrane | 4040 |

| Power consumption | 2.5 kw/h |

| Water use efficiency | 50% |

| Size | 1870X650X1850mm |

OZONE GENERATOR

| Water type | Plain water | Drinking water | Spring water |

| Ozone concentration | 0,1-0,3mg/L | 0,2-0,4mg/L | 0,4-0,6mg/L |

| Ozone addition size | 1-2 gramm/ton | 2-3gramm/ton | 3-5gramm/ton |

Ozone is more powerful than chlorine in oxidizing disinfection. It can not only thoroughly sterilize and disinfect, but also neutralize harmful components in water, remove heavy metal ions and other impurities such as iron, manganese, sulfide, benzene, phenol, organophosphorus, organochlorine, cyanide, etc. Germicidal efficiency is better than chlorine disinfection and UV disinfection. Unlike chlorine, residual ozone can decompose into oxygen and does not cause secondary pollution. After ozone processing, the water is colorless and odorless and tastes good. This is one of the main criteria determining the quality of drinking water.

WATER STORAGE TANKER 2T

As you know, tankers are needed to store water before and after filtration. We offer you 2 stainless steel tankers of 2T each. We can also supply larger storage tanks at additional cost upon customer request.

|

|||||||||||||||

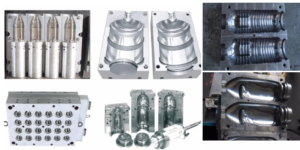

PET CONTAINER HIGH AIR FORMING EQUIPMENT

1). This machine is characterized by low cost, high efficiency, easy operation and maintenance, and stable operation with PLC.

2). Automatic rotation and revolution of the infrared heated heater ensures even distribution of heat production, which improves the speed of glass formation.

3). By adjusting the voltage control area inside the PLC, which can adjust the temperature of the infrared lights on the pre-heated film, and the humidity, which can continuously change, the high level of adjustment ensures high quality.

4). High level of safety with safety automatic locking device in every mechanical movement, which makes production a perfect safe environment even if certain order is broken.

5). A FESTO air cylinder was used to prevent contamination and noise.

6). The air pressure scheme of the machine uses different atmospheric pressures for impact and mechanical action by blowing and dividing the action into three parts.

7). Provides strong clamping force with high pressure and internal and external connections to lock the mold.

8). The pneumatic diagram on the machine serves for ease of understanding and also for the safety, reliability and unique design of the case.

9). An ideal cooling system makes finished dishes flawless.

10). Low error rate: less than 0.2% percent.

| Pet bottle top air forming equipment | |

| Produced | China |

| City | Shanghai |

| Production capacity | 800-1200 units/hour |

| Container dimensions | 0.25L-2L |

| Material | Carbon metal |

| Heating oven | Using a quartz heater |

| Main equipment size | 160X60X161cm |

| Heating equipment size | 187x63x145 cm |

| Capsule length | 15mm-350mm |

| Capsule internal diameter | F5mm-38mm |

HIGH PRESSURE SPECIAL AIR COMPRESSOR

We need a special compressor with a pressure of 3.0 Mpa to produce PET bottles. With this compressor, your equipment will work flawlessly and at the same standard. By having compressors that cannot deliver air at the required pressure, you will not be able to produce a quality product and will cause an increase in defective products.

| High pressure special air compressor | |

| Produced | China |

| City | Shanghai |

| Pressure output power | Up to 3.0 MPa |

| Air supply volume | 2m3/min |

| Motor power | 22kw/h |

| Rotation speed | 630 RPM |

| Weight | 680 kg |

MONOBLOC WATER POURING EQUIPMENT (8-8-3)

3-in-1 water injection equipment, all processes take place without human intervention, inside the equipment protected by glass. Our equipment is made of high-quality sus304 stainless steel, and the line can pour water from 500-1.5L. The equipment washes well before pouring water into the pet containers, for this there are 8 washing channels and fills the pet containers with water through another 8 watering channels. and closes the pet containers filled with water through 3 channels. It includes washing, filling, covering three parts in one body. The filling machine is mainly used for non-carbonated drinks such as mineral water, pure water, still wine and drinks, with a speed of 2000 units per hour. The design of the machine reduces the contact time of the drink with the external environment, improves sanitation and guarantees safety.

| 8-8-3 monoblock packaging equipment | |

| Produced | China |

| City | Shanghai |

| Pressure output power | 2000 pieces (500ml) |

| Material | Stainless metal |

| Working power | 3.5kw/h |

| Size | 1750*1450*2350 mm |

| Weight | 2500 kg |

| Control Panel | PLC control |

LABELING EQUIPMENT FOR VESSELS

Adhesive labels are used to give product name and brand information to pet bottles. These in turn are glued using special equipment. The equipment automatically senses each product through special laser sensors and is virtually error-free.

| Labeling equipment | |

| Produced | China |

| City | Shanghai |

| Production capacity | 1800 units/hour |

| Paste field | L<300mm, H<120mm |

| Speed of operation | 30 dishes/min |

| Bonding accuracy | ±1.5mm |

| Size | L1900*W800*1450(mm) |

| Voltage | 220V |

| Power consumption | 420W |

| Weight | 250KG |

DATE PRINTER ON PACKAGING PET CONTAINER

A modern specially designed cartridge printer will serve you long and flawlessly. With this equipment, dates and other information can be printed on cardboard boxes and any other surface.

| Date or Product data entry printer | |

| Produced | China |

| City | Shanghai |

| Print out | 150-600 dpi |

| Cartridge performance | 1,500,000 products |

| Speed of operation | 60 dishes/min |

| Print accuracy | ±0.01mm |

| Size | L1900*W300*1450(mm) |

| Voltage | 220V |

| Power consumption | 50W |

| Weight | 30KG |

PRODUCT PACKAGING EQUIPMENT

This equipment is used for the final stage of product production. The equipment wraps the bundle product using a film in a special roll position and sends it to the hot tunnel. As a result of the temperature of the tunnel heating the film to the required level, the product is tightly packed together and hardens in normal air. In this way, the product is ready for sale in the market.

1. Periodic review and protection of the product.

2. Double size ventilation duct system ensures perfect packing.

3. The temperature is automatically controlled.

4. Imported frequency converter serves for fast step control

5. A cooling system that ensures that the products quickly fall into perfect shape.

6. The control panel is safe and simple to operate.

7. The counting position can be adjusted according to the size of the product

8. Tunnel dimensions can be customized according to your requirement.

The equipment is suitable for packing mineral water, bottled beer, drinks, etc. without a bottom layer (or with a bottom tray). It is advisable to use PE film for perfect packaging of goods. The whole production process adopts the customized technique produced by German technology. The main parts are used from well-known companies such as OMRON, MITSUBISHI, FUJI, etc., which ensures stable and long-term performance.

| Product packaging equipment | |

| Produced | China |

| City | Shanghai |

| Maximum packing size | L450xW560xH360mm |

| Packing speed | 2-5 blocks/min |

| Film width | 550mm max |

| Conveyor weight lifting | 30 kg max |

| Size | L1150xW910xH1860mm |

| Voltage | 220V |

| Power consumption | 50W |

| Weight | 250 kg |

Based on 0 reviews

Show reviews in all languages (3)

There are no reviews yet.