Grain and legumes cleaning equipment (elevator)

This equipment is used to clean cereals, various seeds, corn, pistachios and legumes from straw, dust or dead grains.

We offer you 3 different types of this equipment. They differ in production capacity, volume, energy consumption, sieve size.

13,000$

Principle of operation of the equipment

The main method of cleaning seeds is an air sieve separator. The equipment uses a combination of air and sieves to separate the seeds by size, shape and density. Depending on the model of the equipment, up to eight sieves are fixed. In all cases, the principles of cleaning are the same. The grains are poured into a bunker, where they are evenly distributed through a feeding roller and transmitted through a controlled door in the upper sieve. In this case, the grains are subjected to primary aspiration using an air barrel, from which straw, dust or dead grains are removed. The grains are then sieved to separate them in width and thickness. After separation, the sorted grains enter the air sieve and the aspiration chamber, where the remaining excess particles are absorbed by a strong air flow.

Sorted grains and mixtures are automatically thrown into separate tubes. These machines are suitable for efficient cleaning of beans, wheat, soybeans, sesame, corn, flower seeds and other grain-like materials. The soft feeder section and delivery belts provide efficient cleaning without damaging the grains. Parts of highly functional equipment can be easily replaced for various types of cleaning. To process different seeds, you just need to change the size of the sieve.

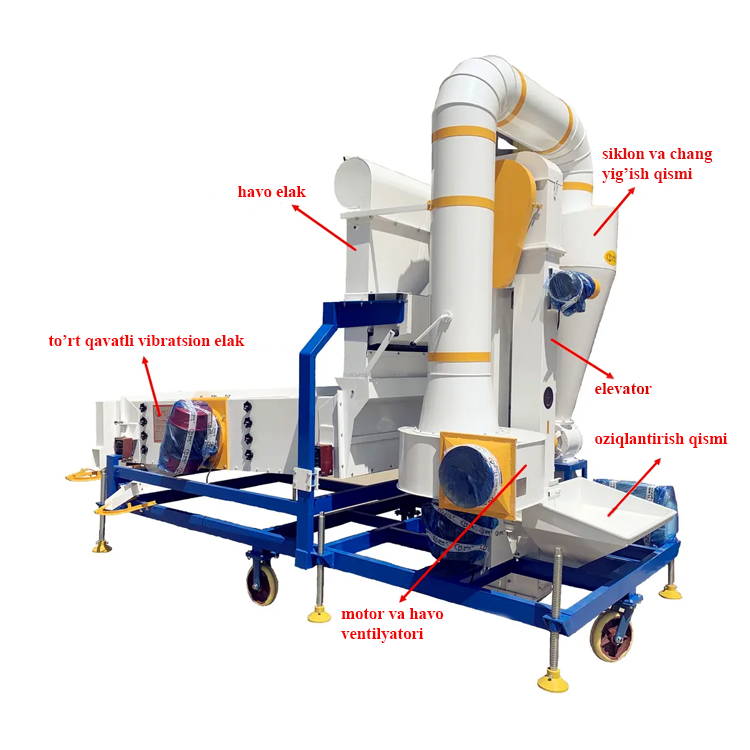

Overview of equipment

Advantages of equipment

- Efficient working capacity

- Only whole unrefined grains come out of the elevator

- Air flow has the ability to adjust for different products

- Indoor air duct, environmentally friendly and does not emit dust

- The vibrating sieve is of high quality and can be easily cleaned.

- Due to the presence of wheels, it is easy to change the location of the equipment

- High productivity and ease of operation

- Solid equipment, consisting entirely of iron construction

- Has a cyclonic aspirated fan

- The low-level bunker is equipped with a control device. Rubber ball specially designed to check whether the sieve holes are clogged

- There is an option to adjust the air supply

Equipment parts

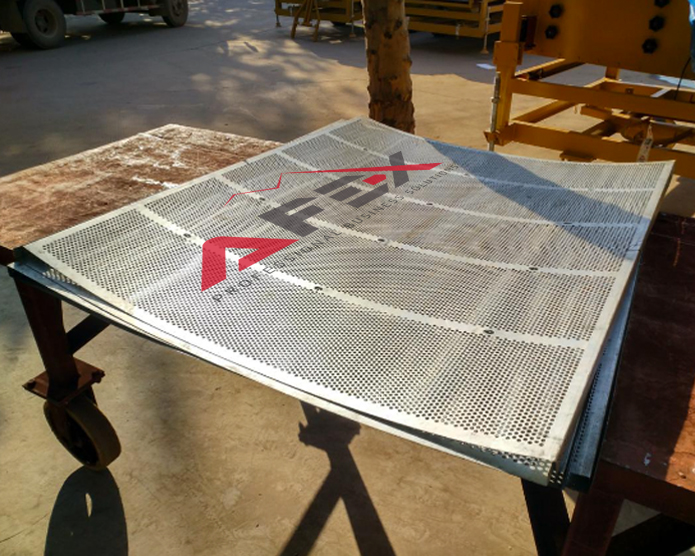

Sieves

Technical characteristics

|

Model |

Production capacity | Capacity | Equipment weight | Equipment size | Sieve size |

| AF-3DX | 3 tons / hour | 7.54 kw | 1750 kg | 4790x1800x3050 mm | 2000×1000 mm |

| AF-5DX | 5 tons / hour | 9.9 kw | 1850 kg | 5430x2060x3200 mm | 2400×1250 mm |

| AF-7DX | 7 tons / hour | 10.3 kw | 2100 kg | 5640x2350x3560 mm |

2400×1500 mm |

There are no reviews yet.