Toilet paper and paper towel production line AF-L016

1 in stock

Day by day, sales of sanitary hygiene products are flourishing. At present, many of our customers are contacting us for toilet paper production line from maclatura. Of course, we also have this line and we can deliver it to you, but the line we are recommending to you is designed for the production of products from cellulose rolls, not from paper. We would like to remind you that AFEX-GROUP LLC relies on the experience of developed countries before recommending any equipment to you. Currently, manufacturers of toilet paper, which is needed for our domestic market, have reached the level of importing raw materials from foreign countries. Russia is mainly a supplier of paper, but a smart businessman should ask himself why the Russian state does not process them. The answer is clear, Russian citizens prefer 100% cellulose toilet paper. Currently, our buyers of products made from secondary raw materials are mostly representatives of the population located in the outskirts of the regional center. However, the demand for cellulose napkins, toilet paper and paper towels among buyers in our domestic market is increasing year by year. In the next 3-4 years, 90% of our population will start using these products. It is a simple economic law that buyers move towards quality as the income of the population increases. Let us introduce you to a highly profitable industry.

20,900$

1 in stock

We always give you a choice. With the help of the table below, you will be able to draw a conclusion through the comparative table of toilet paper made from secondary raw materials and cellulose.

| Advantages and disadvantages of toilet paper made from cellulose and secondary raw materials | ||

| Characteristics | Cellulose | From secondary raw materials |

| It is problematic for the sewage system and completely soluble in water | It dissolves completely in water | It dissolves partially and slowly |

| Softness and risk of body injury | Soft, safe | Rough and less flexible |

| Different colors can be used | It is possible | Not allowed |

| Possibility to add aromatizers | It is possible | Not allowed |

| Compliance with hygienic requirements | Gives a full answer | Partially answers |

| The risk of causing allergic diseases | It does not cause allergies if no flavoring agent is added | It causes allergies if a large amount of chlorine is used during processing |

| Installation of inner bushing | It is possible | Partially possible |

| Ecology and impact on the environment | Trees are cut | Saves trees |

| Use of embossed patterns on the surface | It is possible | It is possible only when it is produced from high-quality office paper |

| The possibility of leaving a break line | It is possible | It can be inserted, but there is a high risk of breaking during the paper wrapping process |

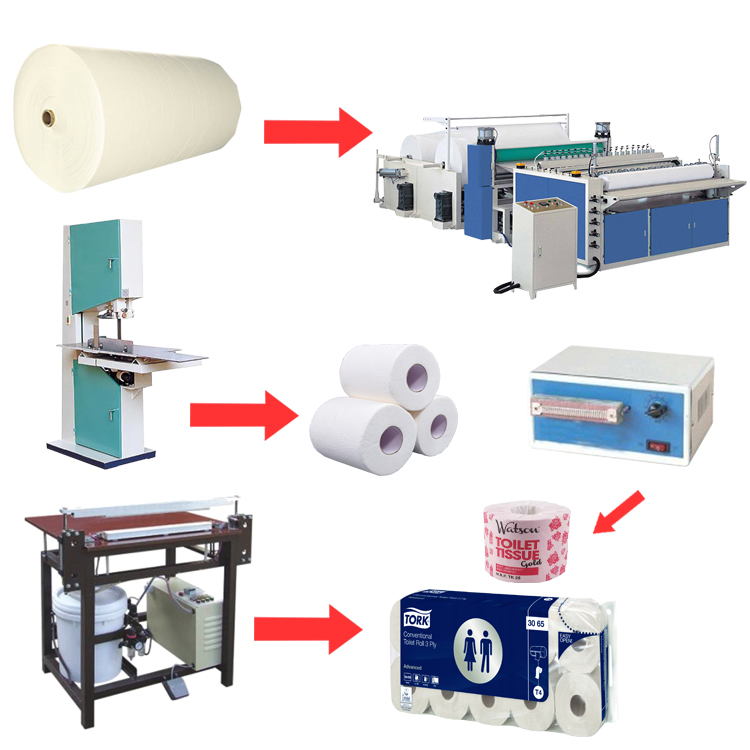

PACKAGING EQUIPMENT FROM LARGE PACKAGING TO SMALL PACKAGING

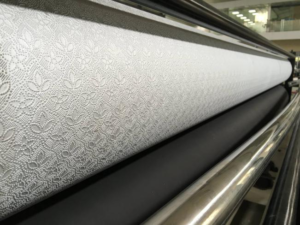

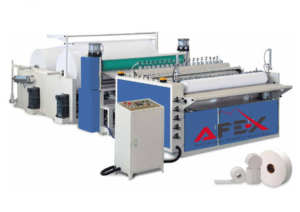

First of all, before starting work, you need to plan how many layers of toilet paper to produce. Currently, we see that manufacturers in our country are making 1, 2, and in some cases 3-story. The most common is certainly 2-story. You can make 1, 2, 3 layers in our equipment. On request, we can provide you with a special embossing shaft for an additional charge.

| Small wrapping equipment | |

| Equipment model | XTGK-1850 |

| Paper width(mm) | 04.дек |

| Production capacity (in 8 hours) | 1.2t |

| The final product is diametric | F50-1800mm (width and diameter vary) |

| Inner bush diametric | F30-55mm |

| The raw material is diametric | Standard 1100mm (other sizes available) |

| Raw material inner sleeve | 76mm |

| Winding speed | 150-280m/min |

| Setting procedure | Through PLC computer control |

| Number of floors | 3 floors |

| Determining the cutoff line | 2 blades, 150-300mm |

| Pneumatic System | 3-valve compressor |

| Power consumption | 5.5kw-15kw varies depending on the speed |

| Size | 6200*2600*800mm |

| Weight | 5 tons |

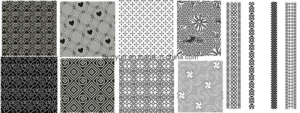

Patterns can be changed according to your requirements, and it is also possible to install a company name or logo.

SMALL ROLL CUTTING EQUIPMENT

This saw serves to cut the small rolls created by the above equipment into a special small size. If you want to make toilet paper, you need to cut it 10-12 cm long, and if you want to make paper towels, you need to cut it longer. This equipment can be used for toilet paper with or without an inner liner.

| Small package cutting equipment | |

| Cutting length(mm) | Changeable |

| Working capacity (tons/day) | 01.май |

| Cutting length(mm) | 3750 |

| Diameter(mm) | 1300*70*1800 |

| Weight (kg) | 560 |

| With and without bushing | Vt is intended for both |

| Power consumption(kw) | 1.1 |

SPECIAL IRONING EQUIPMENT FOR GRAIN PACKAGING

With this equipment, we can package one or two toilet rolls that are not yet made and that people will need. After all, demand should be taken into account when doing every job. A grain-packed product can come in handy when traveling to the mountains or other places. Also, with this equipment, you will have the opportunity to use it for packaging other products (napkins, envelopes, etc.).

PACKAGING EQUIPMENT

And the last stage, as always, is the block packaging equipment for convenient delivery of the product to the customer. Depending on the requirements of the buyer in the area where you live and plan to sell your product, you can pack up to 2, 4, 6, 8. When you order a packing bag, don’t forget to leave holes in it that are easy to grip by hand. This provides additional convenience for the buyer who receives your product. The packaging package is ready-made and closed on three sides. Then, after putting the product in it by hand, the upper part is closed well using the following equipment.

How much income toilet paper production will bring you, equipment costs are given below. We have tried to write the account books as accurately as possible. If you do not allow your goods to remain in your warehouse through good marketing, you will have the daily income shown in the table below.

EXPECTED PROFIT FROM THE BUSINESS

The above table was issued without calculating taxes at the expense of an entrepreneur whose place of production is his own

| Name of products and services (1 package for 60g product) | Account and price |

| Raw material (cellulose) | 14 000 000 soums |

| Inner sleeve 170 cm long (170 gr) | 1000 soums |

| Package for packaging (6 pieces) | 420 soums |

| Consumed electricity (12 hours per 1 ton) | 13.5kw*12=162kw (59,940 soums) |

| Work force 4 people (for 1 ton of product) | 220,000 soums (1.5 million soums monthly) |

| Raw material (cellulose) for one package | 50 gr*14 soums=700 soums |

| Bushing for one roll | 170 cm/10 cm=17 pcs. 1000/17=59 soums |

| Prices of products for the production of 1 bag (6 pieces). | 20000/6=3330 pochka

6*700 soum4200+59*6=354 soum+420 soum=4974 soum |

| Cost of labor and electricity token for 1 piece of product | 277 bags of products are produced in 1 hour

Electricity: 13.5*370=4995 soums Workers: 18330 soums, the price of 4 workers for 1 hour 4995/277=18 soums of electricity for one bag 18330/277=66 soums for workers’ wages for 1 bag So 4974+84=5058 soums is the cost of 1 bag of products |

| The wholesale market price is 6250 soums | 1250 soums*3330 units=4,162,500 soums, your profit for 1 day!

|

Based on 0 reviews

Show reviews in all languages (4)

There are no reviews yet.