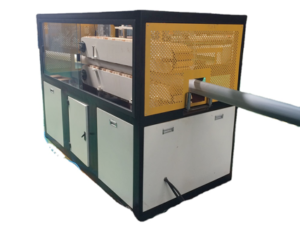

Production line of household hoses

Out of stock

Our people have been engaged in horticulture and agriculture since time immemorial, because the climate and natural conditions of our country provide ample opportunities for horticulture and agriculture.

39,700$

Out of stock

Even now, these two areas form the basis of one of the developed fields in our country – agriculture. Providing comfortable conditions and modern equipment and technologies for the workers of our people is the main goal of AFEX-GROUP.

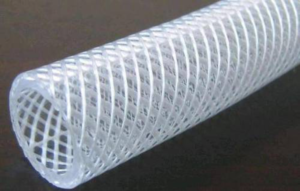

For this reason, our production line, which is presented to you today, produces household hoses, which are very necessary for our people. Our equipment package produces double-layer hoses. Let’s get acquainted with the general information about this production line.

A.

Working area: Indoors, indoors

Humidity: 85% non-condensing

Temperature: 0-40 degrees

B.

Power source: motor, 3 phase, 380V, 50Hz

Water cooling: Pressure greater than 0.4MPa, 2m cubic hour

C.

Production diameter: 13-32mm

Material: PVC soft granule, PP

Production volume: 5-10m/min

Installation power: 75kw

Power consumption: 45kw

Colors: Blue and white (on request)

General dimensions: 15000m*3000mm*2350mm

Total weight: 8000 kg

The set of equipment we need is as follows:

1. Raw material delivery equipment (2)

2. Drying equipment (2)

3. First layer extruder (1)

4. Second layer extruder (1)

5. Mold (2)

6. Water cooling equipment (2)

7. Supply equipment (2)

8. Thread gluing equipment (1 piece)

9. Oven (1)

10. Color line drawing equipment (2 pieces)

11. Wrapping equipment (1)

So, we have learned all the general information we need. Now we can consider the production step by step.

Vacuum delivery equipment

| Vacuum delivery equipment | |

| Material | Stainless metal |

| Performance | 200 kg/h |

| Motor power | 1.5 kw/h |

Drying hopper

In the next process, our above equipment dries and melts some wet raw materials and prepares them for the next processes.

| Drying hopper | |

| Material | Stainless metal |

| Weight | 50 kg |

| Heating power | 4 kW |

| Parrack power | 180 W |

| Error rate | -1,+1 degrees |

Mold

The mold will decide the diameters of your hoses. You can set the diameters to the size you want.

| Mold | |

| Material i | 40 Chromium alloy |

| Surface part | Chrome |

| Diameters | 13mm, 16mm, 20mm, 25mm, 32mm |

| Air pump | 0.37 sq |

The first layer is the extruder

As for the next equipment, the task of the equipment is to mix different raw materials together. If we pay attention to the photo, the drying equipment is also placed in the upper part of the equipment. The mold is placed in the last part of the equipment (on the left).

| General description | |

| Electrical parts | Inverter-ABB

Contactor-SIEMENS Temperature control-OMRON |

| Production volume | 50-65 kg/h |

| Advantages | Brand company parts, real-time quality control |

| Screw | |

| Diameter | 65 mm |

| Material | 38 chromiumMoAIA, nitrogen |

| Heating system | Heater made of stainless steel and aluminum |

| Heating power | 10 kW |

| Cooling | |

| Type of cooling | Through the tubes |

| Cooling accuracy | -1,+1 degrees |

| Material | 38 chromiumMoAIA, nitrogen |

| The progress of the process | |

| Main motor power | 18.5 kW |

| Speed | Can be changed |

| Main motor speed | 1441 times/min |

Cooling system

The hose that came out of the extruder is very hot. This can cause the hose to be accidentally deformed. For this reason, we need to cool them in the next process. For this we need the above equipment. They cool the hose by pouring water over the hot hose.

Supplier equipment

| Cooling system | |

| Length | 2.5 m |

| Material | Stainless metal |

| Type of cooling | With water |

| Pump motor power | 0.12 kW |

And the turn of the cooled hoses came to the supplying equipment. The function of this equipment is to adjust and deliver the hose to the line drawing equipment.

| Supplier equipment | |

| Type | 2 parts |

| Grip length | 520 mm |

| Motor power | 0.75 kw*2 |

| Speed | 0.3-15 m/min |

Threading equipment

| IP sealing equipment | |

| Motor power | 1.5 KW* 2 pcs |

| Inverter | ABB |

| Speed | 0-12 m/min |

| Number of reels | 34 |

| Reel | Galvanized |

| Spiral tube diametric | 13mm, 16mm, 20mm, 25mm, 32mm |

| Center section height | 1000mm |

| Coil material | Stainless metal |

Now it is the turn of the line drawing equipment, one of the largest pieces of equipment on the production line. You can see how the equipment is capable of drawing lines in the file below. PP is used as raw material for equipment.

Oven

Now it’s time to heat the finished hose. The above equipment is the same term for this.

| Oven | |

| Type of heating | Heating Vacuum |

| Heating power | 4 KW |

| Management system | Automatic |

| Temperature control | Automatic |

| Length | 1000mm |

So, we have completed the first layer of our hose. It’s time for the second layer of the hose. The same procedures and equipment are needed for the production of the second layer of the hose. The only equipment that will be changed is that instead of the first layer extruder, the second layer extruder will be installed, and instead of the thread gluing equipment, the equipment for drawing 2-color lines will be installed. The equipment can draw 2 different colors on the hose at the same time.

Color plotting equipment

| Color plotting equipment | |

| Screw diameter | 25mm |

| Length-diameter ratio | 25:01 |

| Production volume | 20/min |

| Rotation speed | 38 chromiumMoAIA, nitrogen |

| Material | 1.2*2 sq |

| Heating power | 2 |

| Main motor power | 0.75 sq |

| Temperature control | Japan Omron |

| Converter | ABB |

At the last stage of the process, the finished hoses are wrapped and made ready. This is the end of the production. Hoses are ready for sale.

| Prices | |

| Raw materials and equipment (2) |

39 700$ |

| Drying equipment (2 units) | |

| Extruder (1st floor) (1 piece) | |

| Extruder (2nd layer) (1 piece) | |

| Mold (2 pieces) | |

| Cooling equipment (2 units) | |

| Supply equipment (2 units) | |

| Threading equipment (1 piece) | |

| Oven(1) | |

| Color bar equipment (2 pieces) | |

| Wrapping equipment |

Based on 0 reviews

Show reviews in all languages (1)

There are no reviews yet.