Egg flake container production line

Out of stock

Great attention is paid to poultry and egg production in our country. The consumption of egg products is also increasing year by year. In this place, the production of egg containers is becoming a profitable business. Egg dishes are made by recycling uncomplicated newspapers, books, boxes, magazines and other types of paper waste. This is not only an economic benefit, but also an ecologically beneficial business.

19,700$

Out of stock

“AFEX-GROUP” offers our businessmen a compact line that brings a large profit for a small investment.

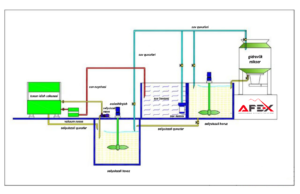

In the diagram below, you can find information about the technological processes of product production, the location of equipment and devices.

3 basins (pools) are required for water and cellulose mass. It is desirable that the dimensions of the basin are 1.5×1.5 meters, the depth is 1.2 meters or 1.5 meters.

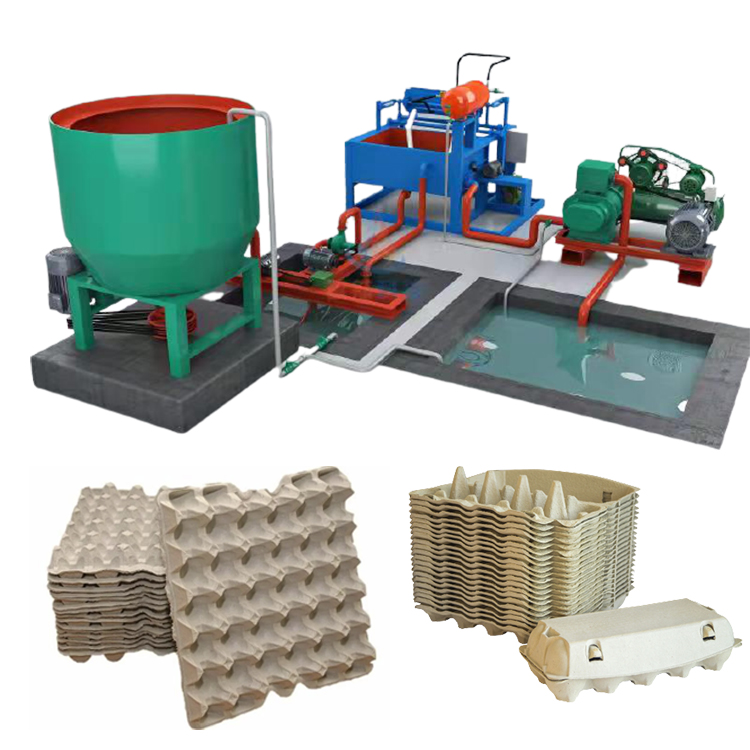

As you can see in these pictures, the raw materials, which are initially waste paper, are made into a slurry using a hydraulic mixer. The prepared cellulose mass is thrown into the first basin. The mass prepared in the first basin is thrown to the second basin to be sent to the equipment. In these technological processes, the water basin ensures the processing of water that has increased during the adjustment of the cellulose mass.

Required raw materials:

All types of waste paper products

Necessary infrastructures to start the activity:

Required area; 50 m² (for equipment)

Total power; 37 sq.

Electricity consumption; 25.9 kw/h.

Paper consumption; 120 kg/h.

Water consumption; 300 liters / hour.

Equipment and devices required for the activity:

1. Hydraulic mixer.

2. Forming equipment.

3. Cellulose pump.

4. Vacuum pump.

5. Water pump.

6 Karcher.

7. Air compressor.

8. Additional parts

Mixer

| Technical indicator | |

| Power | 7.5KW |

| Size | 1600x1600x1550mm |

| Weight | 1000kg |

Mold equipment

In the egg container forming equipment, the number of molds is 3 rows/2 pieces, and it has the capacity to produce 1000 pieces of products in one hour. The size of the products is 31×31 cm, the weight is 55-80 grams. The equipment consumes an average of 100-120 kg of waste paper to produce 1000 pieces of product.

| Technical indicator | |

| Work/output volume | 8-14 pieces/min |

| Power | 3KW |

| Size | 3170x1700x1800mm |

| Weight | 1500kg |

Pump for pulp

| Technical indicator | |

| Power | 5.5 KW |

| Size | 900x300x300mm |

Vacuum pump

| Technical indicator | |

| Power | 7.5 KW |

| Size | 1500×800 x800mm |

Water pump

| Technical indicator | |

| Power | 1.5 KW |

| Size | 380x240x240mm |

Karcher equipment

| Technical indicator | |

| Power | 3 KW |

| Size | 100x560x560mm |

Compressor

| Technical indicator | |

| Power | 7,5 KW |

| Size | 1300x700x900mm |

Additional parts

Egg container drying system.

In this project, the customer is required to organize a drying system at his own expense. We offer three types of drying methods for customers: natural drying process, semi-automatic brick tunnel drying system, metal tunnel-automatic conveyor drying system.

In terms of fuel, you can use electricity, wood, diesel, coal and natural gas for all drying systems.

Because the automatic conveyor drying system and the fully automatic metal drying system have a high degree of automation, the labor requirement is low.

For the drying system, fuel consumption per hour:

Electricity – 20 kW.

Natural gas – 22-32 cubic meters.

Diesel – 18-25 liters.

Coal – 50 kg.Video footage of the process

There are no reviews yet.