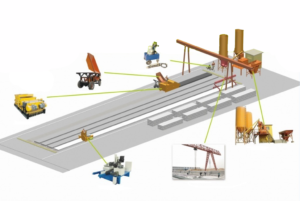

Reinforced concrete slab production line

Out of stock

The business of manufacturing concrete products is one of the profitable activities, as it covers many areas. ”AFEX -GROUP” offers modern technologies in the production of reinforced concrete slabs, one of the concrete products.

108,500$

Out of stock

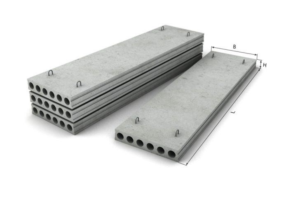

Reinforced concrete slabs – these products are mainly used for the construction of residential buildings, roads and bridges. It has been tested for many years and is considered one of the most reliable products.

Now the construction industry is developing, new houses, residential complexes are being built, and new roads are being laid. All this increases the demand for concrete structures. Of course, the demand is high, which is explained by the rapid development of the construction industry.

“AFEX-GROUP” provides close practical support for entrepreneurs who want to start this business activity.

product image

Technological processes of product production

Preparation of the concrete mixture – the concrete mixture must be moistened in order to pour the slab evenly.

Preparation of armature constructions – armatures are pulled taut with the help of wire pulling equipment.

Positioning the concrete slab to direct the pouring equipment.

Delivery of raw materials with the help of a machine that transports raw materials.

Cutting the prepared products into the specified sizes.

The following raw materials are needed for the production of concrete slabs:

Cement, sheben, sand, metal fittings.

Necessary infrastructures to start the activity:

Required area: Must not be less than 500 m².

Electric power: 70 KW/380 V.

Number of workers: 4-5 people.

The main source of all infrastructures is water.

The special crane required for this project will be installed by our company as agreed upon by the client.

Line equipment:

1. Cement storage bunker (silo).

2. Equipment for measuring raw materials.

3. Mixing mixer.

4. Raw material delivery machine.

5. Concrete slab pouring equipment.

6. Equipment for cutting concrete slabs.

7. Wire drawing equipment.

All technological processes in the production of products begin with the loading of raw materials into the measuring equipment.

Cement storage hopper – cement product is loaded into this container from the top. Loaded cements are loaded from the bottom using a screw conveyor to the mixer in the required amount to prepare the mixture.

| Technical indicator | |

| Model | 100 Т |

| Silo diameter | 3,000mm |

| Silo cylinder height | 9,810mm |

| The height of the silo cone | 2,579mm |

| Silo height | 19,799mm |

| Total height | 23,177mm |

| Unloading height | 7,400mm |

| Thickness | 3-8mm |

| Total weight | 8T |

| Technical indicator | |

| Body diameter | 273 mm |

| Screw diameter | 243 mm |

| Rotation speed | 209rpm |

| Delivery | 50t/h |

| Power | 7,5kw |

| Length | 9 metr |

Raw Material Weighing Equipment- This equipment weighs the specified amount of sand mixed with sheben and fine stone on a scale and delivers it to the loading hopper to prepare the mixture. The equipment is capable of delivering 56 m³ of stone and sand raw materials per hour. All processes are managed in the control panel.

| Technical indicator | |

| Model | PLD1200 |

| Bunker capacity | 1200L |

| Bunker number | 3 |

| Opportunity | 56 m/h |

| Accuracy | 2% |

| Loading height | 2.9 m |

| Delivery speed | 1.25m/s |

| Power | 9kw |

| Size | 8000*2200*1680 mm |

| Weight | 3000 kg |

| Total weight | 5000 kg |

Mixing mixer- the equipment loads the stone and sand raw materials in the loading hopper, the cement product is delivered directly from the cement storage hopper to the screw conveyor, and then mixed until it is wet with water. All processes are controlled by the control panel. .

Mixing mixer- the equipment loads the stone and sand raw materials in the loading hopper, the cement product is delivered directly from the cement storage hopper to the screw conveyor, and then mixed until it is wet with water. All processes are controlled by the control panel. .

| Technical indicator | 800l |

| Loading hopper | 750l |

| Internal capacity of the mixer | 80/60mm |

| Maximum stone size | 30-35m3/h |

| Working power | 18,5kw |

| Mixer power | 5,5kw |

| Pump power | 0,75kw |

| Size | 4600*3030*5780mm |

| Weight | 4200kg |

Raw material delivery machine-The raw material mixing mixer delivers the mixture to the concrete slab forming equipment. The car’s carrying capacity is 1.5 tons.

Raw material delivery machine-The raw material mixing mixer delivers the mixture to the concrete slab forming equipment. The car’s carrying capacity is 1.5 tons.

| Technical indicator | |

| Fuel type | Diesel |

| Size | 2600*2200*1550mm |

| Weight | 1500kg |

The concrete slab pouring equipment forms the concrete mixture into slabs. The length of the equipment is from 4.5 meters to 15 meters, the height is 220 mm, and the width is 1200 mm. On this equipment, 500 meters of reinforced concrete slabs can be poured in one day (8 hours). In the production of products, there are different types of plate holes, for example: circle, drop and oval. The customer can purchase one of these types when purchasing the equipment.

The concrete slab pouring equipment forms the concrete mixture into slabs. The length of the equipment is from 4.5 meters to 15 meters, the height is 220 mm, and the width is 1200 mm. On this equipment, 500 meters of reinforced concrete slabs can be poured in one day (8 hours). In the production of products, there are different types of plate holes, for example: circle, drop and oval. The customer can purchase one of these types when purchasing the equipment.

| Technical indicator | |

| Hole type | Oval |

| Power | 29kw |

| Texture | 60-65m/h |

| Size | 4600*1900*1400mm |

| Weight | 1500kg |

Biton slab cutting equipment – after the formed concrete slabs have dried, they are cut to the required length.

Biton slab cutting equipment – after the formed concrete slabs have dried, they are cut to the required length.

| Technical indicator | |

| Blade diameter | 700mm |

| Cutting thickness | 220mm |

| Cutting length | 1200mm |

| Power | 11kw |

| Rotation speed | 1440rmp/min |

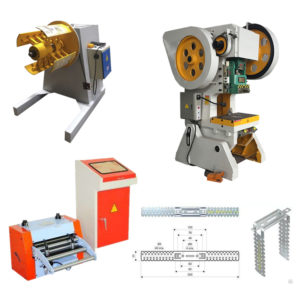

Wire tensioning equipment – Steel reinforcements are used to increase the strength of concrete slabs, this equipment pulls the reinforcements before pouring the slab.

Wire tensioning equipment – Steel reinforcements are used to increase the strength of concrete slabs, this equipment pulls the reinforcements before pouring the slab.

| Technical indicator | |

| Rated power | 650 mpa |

| Nominal pressure | 30,8 kn |

| Pump power | 2,2 |

| Size | 2150*500*500mm |

| Weight | 120kg |

| Technical indicator | |

| Diameter | 5mm |

| Number | 200 pieces |

| Technical indicator | |

| Disc diameter | 700mm |

| Cutting thickness | 220mm |

| Number | 5 ps |

There are no reviews yet.